Jun 21 2013

What is a nanoengineer? It’s a question nearly 20 seniors, who, this June, earned the first bachelor’s degree in nanoengineering offered at the University of California, San Diego, have learned to answer as they tackle the questions and expectations of their parents and potential employers.

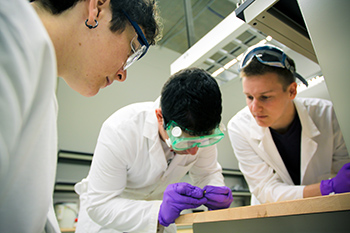

From left, seniors April Pereia, Andrew Baker and Brandon Westerberg at work in the senior design lab for nanoengineering undergraduates. Photos by UC San Diego Jacobs School of Engineering

From left, seniors April Pereia, Andrew Baker and Brandon Westerberg at work in the senior design lab for nanoengineering undergraduates. Photos by UC San Diego Jacobs School of Engineering

They are, after all, the first crop of graduates in a degree program that is still unique in engineering schools in the United States. Although most engineering programs now offer courses about engineering at the nanoscale, very few provide a focused curriculum dedicated to this rapidly growing field. UC San Diego was the first in the nation to create a Department of NanoEngineering in 2007 and began offering it as an undergraduate degree program in fall 2010. Since then, undergraduate enrollment has grown from 51 students to 273, and is expected to reach nearly 400 students this fall with the arrival of a new crop of freshmen. The department took over the chemical engineering program in 2008. That program’s enrollment grew from approximately 135 undergraduate students to more than 550 this year. The department plans to introduce a new materials engineering degree in 2014 to complete the growth of the department’s undergraduate engineering degree programs.

“In the fully developed NanoEngineering Department, we will administer the more traditional engineering programs of Materials Engineering and Chemical Engineering, along with our core focus program of NanoEngineering, which combines aspects of Materials Engineering and Chemical Engineering directed at the unique properties and enabling characteristics of nanoscale materials. This will serve as a model for future departments of this kind,” said Kenneth Vecchio, professor and chair, Department of NanoEngineering.

Stripped down to the most basic process, nanoengineering “is the manipulation of molecules and atoms in order to construct things from the bottom up,” said Cody Carpenter, who plans to return in the fall to earn a master’s in nanoengineering and then go into industry. Carpenter has been working in the research laboratory of Professor Liangfang Zhang, who is developing nanoscale therapeutics for cancer and other diseases that can evade the body’s immune system. Carpenter called nanoengineering “the second industrial revolution” and it’s clear from interviews that he and his fellow graduates feel they are embarking on an open-ended professional journey that is simultaneously pioneering and immensely practical. They are quick to point out that nanoengineering is not exactly a new science, but, rather, an enabling technology with applications in most industries from energy, to medicine, to computer science. The nanoengineering curriculum gives them a strong foundation in physics, chemistry and biology and they are required to select a focus area in a traditional discipline such as materials science, electrical engineering, mechanical engineering, bioengineering or chemical engineering.

“We encourage our students to think about real problems and to think bigger than their coursework. How could you make an impact? There are bottlenecks in almost every technology,” said Professor Donald Sirbuly. “The point of nanoengineering is to build the next-generation engineer. I think they’re going to have a very broad skill set.”

Beautiful. Creative. Cutting edge. Challenging. Open ended. Hands On. And most frequently, experimental. These are the words the students use to describe the program they helped to create simply by being among the first to do it. And, bolstered by the act of achieving a degree in such a difficult field, they feel confident about their unique skill set and academic experience.

“Once you understand that all fabrication-based companies are using nanoengineering, it’s all about making that connection between what they already know to what you’re doing in the lab,” said Yahya Alvi, who will spend the summer interning at Intel before returning this fall to earn his master’s in nanoengineering. Eventually, Alvi plans to also earn an MBA and enter industry. He is interested in working in the development of new types of medical diagnostics based on nanotechnology.

Like Carpenter and most undergraduates in nanoengineering, Alvi has been actively engaged in research by working in the laboratory of Professor Andrea Tao where he has been learning to control the size and shape of silver and gold nanoparticles and molding them into cubes, triangles, pyramids and octahedrons. It’s as diffult as it sounds. “You’re working on such a small scale that the tiniest change could throw off your results,” said Alvi.

Sirbuly, who along with Tao teaches the two-quarter senior design lab known as Nano 120, said learning about the complexity and sensitivity of processes occurring at the interface of materials is fundamental for students in nanoengineering and gives them a unique mindset as problem solvers. “They get a really good feel for how to work with the materials. That’s a different dimension to being a good researcher in any field,” said Sirbuly. “It’s not enough to just know conceptually what’s going on. We give them real, open-ended problems.”

The senior design lab culminates in students designing a device that solves a real problem in a field of their choice, generally selected from problems faculty researchers are experiencing. Sirbuly said going forward he would like to work even more closely with industry partners to provide problems currently faced in the industrial sector that undergraduate researchers can help tackle. One example is biofouling in which microorganisms grow on wet surfaces, and a challenge many medical and maritime researchers are actively investigating. For marine applications such as underwater hull coatings, antifouling properties are essential to maintain the performance of the vessel, reduce the cost of hull cleaning, and to protect the ship’s components from the corrosive marine environment. On the medical front, instruments and equipment must contain coatings that resist microbial attachment and reduce nonspecific interactions to maintain sterility and minimize cross-contamination. The undergraduate students could research novel nanotechnology strategies that prohibit the growth of organisms on the surface of a material and demonstrate enhanced antifouling properties.