Jun 30 2015

Dai Nippon Printing Co., Ltd. (DNP) will launch a new business applying nanoimprint technology in a variety of uses. These include, the development of ultra-micro machine product-related applications and product planning, the fabrication of templates (molds) and prototypes, as well as mass-production uses. The new business is set for a March, 2015 launch.

Nanoimprint technology is a micro-machining technology designed to press templates on to the surface of such substrate materials as resin, and transfer patterns in scales from nanometer to micrometer in a stable and low cost manner. And in a move that marks yet another domestic first, DNP aims to apply this technology in the operation of an ultra-micro machining business based on a full scale integrated line. This will enable DNP to provide a variety of products, including electronic materials, such as magnetic recording media, light emitting diodes, organic EL, light-guiding panels and photovoltaic cells, along with bio and medical-related materials.

Development Background

In recent years, increased needs have emerged for nano-level ultra-micro machined components and materials that are capable of achieving new functions in a variety of products areas, including optical products such as displays, along with the bio-medical area. A challenge exists, however, given that research organizations and manufacturers often lack specialist knowledge or technology related to the templates and manufacturing processes needed for producing micro-machined goods. In addition, the cost of introducing dedicated facilities compatible with nanometer scale measures is a burden.

DNP embarked on the development of nanoimprint technology used in the miniaturization of semiconductor circuits and electronic equipment, from an early stage, and as a result was able to develop template fabrication based on nanometer scale semiconductor circuit patterns. DNP has also used this technology to establish a track record in the development of ultra-low reflective film that prevents light reflection via the transfer of hundreds of nanometer scale micro bumps on the surface of a transparent film.

The Company has now capitalized on the experiences, know-how and technology of this track record, to commence the operation of an ultra-micro machining business based on a full scale integrated line. This has allowed DNP to answer the strong needs voiced by the industry to engage in a variety of production activities, from template and prototype fabrication, to mass production. The Company will also propose improvements for product application-based template performance and manufacturing processes, and in this way contributed to a broad set of areas.

New Business Contents and Features

- Application developments, proposal-driven planning support and template design.

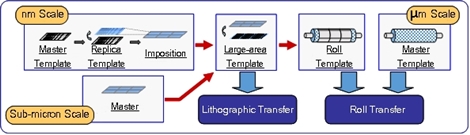

- Fabrication of master templates*

- The fabrication of replica templates based on master templates, and production of large-area templates with arrayed multiple replicas.

- Production of prototypes with transferred patterns, and mass production.

The features of the new business are as follows:

- The provision of thorough support from planning, through development, template fabrication, pattern-transferred prototypes to the mass production.

- The provision of a broad range of ultra-micro machining from nanometer to micrometer scales.

- The provision of roll-to-roll templates that treat large area roll type resin substrates.

- The production of products using a variety of DNP-owned manufacturing facilities.

- Support for performance evaluation and improvements to templates in use.

*Master template:

- It is possible to produce micro patterns of approximately 20nm on the surface of a 6 inch square substrate, and a master template with 3-dimensional configured patterns.

- It is also possible to produce a master template with sub-micron (10 to the minus power of 4 meters = 10 to the minus power of 7 meters) configured patterns on the surface of a large area substrate (1200mm×1000mm).

- It is further possible to produce a 1500mm×930mm size template (roll version or Ballard version) with configured micrometer scale patterns.

It is also possible to provide prototypes that use these master templates to press micro-patterns on to the substrate of resin or quartz glass.

Looking Ahead

DNP will offer this new micro-machining business to a broad array of R&D divisions, including those for device makers, optical components, and life sciences, aiming for sales of 2.0 billion yen in 2016.