With the development of different techniques for the synthesis of nanomaterials, researchers are constantly looking for a more precise instrument for their nanoscale characterization. X-ray diffraction (XRD) is emerging as the most widely used technique for characterizing nanoparticles because of its ability to interact with the electrons of the inner shell of an atom.

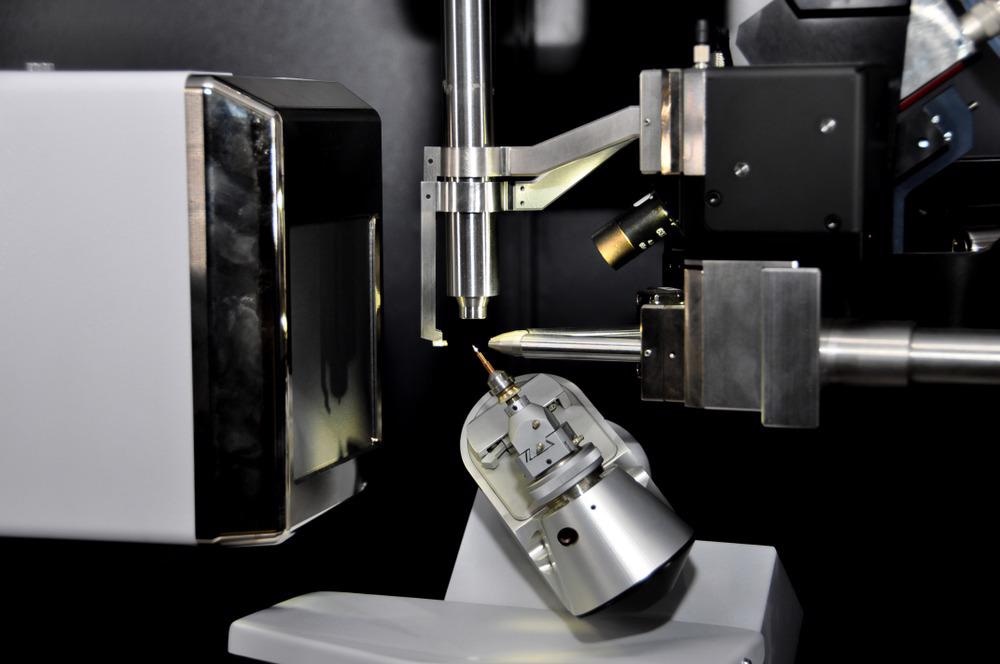

Image Credit: Isuaneye/Shuttterstock.com

Working Principle

One method to generate X-rays (energies range from 100 eV to 100 keV) is by heating a filament in a cathode ray tube. A peak in intensity (constructive interference) occurs when the incident monochromatic beam of X-rays impacts the sample satisfying the Bragg Equation, nλ=2dsinθ.

Here λ is the wavelength of the beam, n is any integer, d is the spacing between diffracting planes, and θ is the incident angle. A detector records and analyses the diffracted X-ray radiation, converting it to a count rate that is subsequently shown on a computer screen.

The intensities of XRD peaks depend on the atomic position within the lattice planes. XRD can therefore be widely used for accomplishing the structural information of nanomaterials such as lattice parameters, phase nature, and crystalline structure. The simplicity with which data can be collected makes it an obvious choice for nanomaterials characterizations.

Other methods involve replacing the sealed tube with a rotating anode as the X-ray source, which has been shown to improve X-ray flux rates.

XRD Peak Broadening in Nanoparticles

Cadmium Sulfide (CdS) quantum dot nanoparticles are extensively utilized in numerous nanoscience and nanotechnology fields. It is possible, for instance, to determine the particle size of these quantum dots by XRD analysis.

As crystallite size approaches the nanoscale, XRD peaks broaden.

Peak broadening increases dramatically as the crystalline size drops 50 to 25 nm. Furthermore, the peak broadening becomes so significant as size goes down to 10 nm that peak intensity starts becoming weak; peaks often overlap and are difficult to identify.

As a result, size-dependent XRD peak broadening has substantial implications for the characterization of nanomaterials.

For instance, if TEM analysis reveals spherical particles with a 10 nm average diameter, but the XRD pattern shows sharp peaks that are more consistent with much larger size particles, then the majority of the bulk sample is not composed of 10 nm particles; instead, they represent only a minority part of the population.

Furthermore, sometimes the nanoparticles of CdS exhibit two structures at a time, namely a hexagonal wurtzite structure and cubic zinc blend polymorphs. Because some of the wurtzite peaks overlap with the zinc blende peaks, in this case, the XRD pattern of the combination seems to have greater relative intensities than wurtzite.

Morphology and Orientations dependent XRD of Nanoparticles

For particles of the same substance with varying morphologies, the appearance of XRD data can vary. It may be possible that the peak locations will not change, but the corresponding intensities of the peaks may.

To understand the relationship between preferred orientations and XRD pattern, the researchers drop casted germanium sulfide (GeS) nanosheets on to XRD sample holder.

Generally, GeS nanosheets are preferred to align parallel to the surface. When the XRD patterns are studied, it reveals a significantly preferred orientation in the [100] direction for drop casted GeS nanosheets but only a minor preferred orientation when synthesized as a powder.

XRD Pattern of Samples Containing Different Particle Sizes

XRD is an elite technique to study nanoparticle samples of varying sizes. Nanomaterial samples that include a mixture of particles with different sizes or shapes can produce more complex XRD patterns.

For instance, nanoplates of wurtzite cobalt sulfide (CoS) show average dimensions of 13 nm corresponding to (100) peak and 5 nm corresponding to (002) peak. As a result, the widths of the (100) and (002) peaks, which are near together, are significantly different.

Conclusion

X-ray diffraction is a powerful tool for characterizing materials and distinguishing between different crystalline phases. However, for nanocrystalline materials with prominent peaks, decimal precisions in lattice constants are challenging to obtain.

There are, of course, problems in the scientific community for further improving the accuracy and resolution of the XRD technique for nanoanalysis.

Nonetheless, we cannot deny that careful examination of the XRD data might provide useful information and aid in correlating microscopic findings with the bulk material. Moreover, current studies are looking at the development of alternative approaches to broaden the applicability of X-ray diffraction.

Continue reading: XRD Analysis of Clay Layers in Carbonate Rocks.

References and Further Reading

C. F. Holder., et al, (2019) Tutorial on Powder X-ray Diffraction for Characterizing Nanoscale Materials, ACS Nano, 13, 7, 7359–7365. Available at: https://pubs.acs.org/doi/10.1021/acsnano.9b05157

S. Mourdikoudis., et al., (2018) Characterization techniques for nanoparticles: comparison and complementarity upon studying nanoparticle properties, Nanoscale, 10, 12871-12934. Available at: https://pubs.rsc.org/en/content/articlelanding/2018/nr/c8nr02278j

AXT. (2021) Benefits of High Flux X-ray Diffraction Studies for Materials Analysis. [online] Available at: https://www.axt.com.au/high-flux-x-ray-for-diffraction-studies-in-materials-analysis/

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.