Feb 16 2011

Glidewell Laboratories, industry-leading provider of dental lab products and services and manufacturer of BruxZir Solid Zirconia dental material, Research & Development team has moved closer to producing transparent nanozirconia by successfully synthesizing 3 nm zirconia nanocrystals produced by "bottom-up" nanotechnology.

The research team, led by Ken Knapp, Glidewell Laboratories' program manager and lead researcher, developed a method for producing non-agglomerated 3 nm nanocrystalline zirconia powder using a revolutionary bottom-up nanotechnology technique known as "gas-phase condensation." The focused effort of the nanozirconia research team over the last year has resulted in new discoveries about the nature of sub-5 nm nanozirconia crystals. Glidewell Laboratories has filed a U.S. patent application on the new ceramic nanotechnology (patent pending). This method consists of colliding high-energy yttrium, zirconium and oxygen ions together in an energetic gaseous phase and condensing yttria zirconia nanocrystal particles resulting from atomic collisions during flight in the gas phase. The condensed yttria zirconia nanocrystal particles are separated from the gas phase and collected in the form of nanocrystalline powder. According to Knapp, "The key to making transparent polycrystalline zirconia material is starting with a non-agglomerated yttria zirconia primary crystal size less than 5 nm. Glidewell’s new gas-phase condensation nanotechnology for producing nanozirconia will allow us to overcome the fundamental polycrystalline birefringence barrier to manufacturing a transparent, high-strength monolithic dental ceramic product."

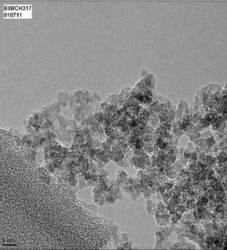

High-resolution transmission electron microscopy (HRTEM) image of Glidewell Laboratories' 3 nm nanocrystalline zirconia material produced by gas-phase condensation "bottom-up" nanotechnology.

High-resolution transmission electron microscopy (HRTEM) image of Glidewell Laboratories' 3 nm nanocrystalline zirconia material produced by gas-phase condensation "bottom-up" nanotechnology.

Conventional nanozirconia powder is typically produced by "top-down" nanotechnology methods such as hydrothermal synthesis (calcining followed by ball-milling). Many of the nanozirconia powders available on the market today are comprised of hard-agglomerated nanocrystals with a primary crystal size of approximately 30 nm. After sintering, typical nanozirconia grain size is between 500-1000 nm. The top-down method is widely used to produce nanocrystalline materials by breaking down larger particles and agglomerates into smaller ones, typically by ball-milling. The bottom-up nanotechnology method builds up nanoscale materials atom by atom or molecule by molecule. Bottom-up nanoscale science and technology is the state of the art for producing the next generation nanoscale materials and devices. The bottom-up method has a lower scale limit on the atomic or molecular level. Additionally, the bottom-up-produced nanocrystalline structures are not altered during the process of forming the nanoscale crystals, whereas top-down methods alter the crystal structure and surface chemistry.

Robin Carden, senior director of Glidewell Laboratories materials research and development said, "Glidewell’s nanozirconia material produced by the gas-phase condensation method overcomes the inherent sub-5 nm crystal size production barrier and hard-agglomeration formations found in conventional nanocrystalline ceramic processing."

Common zirconia dental ceramics are translucent and not transparent as a result of light-scattering during transmission by birefringence and porosity. Light-scattering by birefringence is an intrinsic property of polycrystalline optical materials with an anisotropic crystalline index of refraction. Birefringence is reduced dramatically when the sintered grain size is reduced below 100 nm. Porosity causes light-scattering in the visible spectrum between 400-700 nm, which reduces the zirconia optical transparency.

The future for high-strength esthetic nanozirconia is agglomerate-free sub-5 nm powder. James Glidewell, CDT, CEO and president of Glidewell Laboratories said, "Our continued nanozirconia research efforts, from the fundamental way that zirconia nanocrystals are formed to new sintering methods, will allow us to extend our BruxZir® product life into the next generation of nanocrystalline dental ceramics."

Source: http://www.glidewelldental.com/