Feb 11 2015

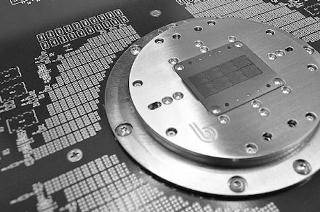

BucklingBeam announced today the release of its new proprietary MEMS (Micro Electrical Mechanical Systems) based technology designed to enhance testability for semiconductor manufacturers worldwide.

With semiconductors continuing to shrink in size in order to meet the requirements of today's increasingly compact consumer electronics, BucklingBeam's precision technology will make an immediate impact on overall quality and the bottom line.

This new, patent-pending MEMS-based solution – Motus™ III SD – is designed for stringent, high-end, high pin count applications requiring fine pitch contact to 100 micron pitch and below for area array and copper pillar IC devices. The new technology provides the highest value wafer test contactor available today. Motus III SD also offers customers greater mechanical precision than competitive MEMS solutions and at a more competitive unit price. With greater than two times the life, unparalleled precision and yield improvement, Motus III SD empowers the semiconductor industry with advanced technology that provides immediate ROI.

"At BucklingBeam, we pride ourselves on providing products that work the first time, every time. We use only the finest supply chain partners and materials available across our entire product portfolio to ensure the best value, quality and performance," said Mike Chrastecky, CEO of BucklingBeam. "We also incorporate stringent process controls to insure exceptional quality, and provide the best service personnel in strategic service centers to ensure maximum up time. The highest quality and highest value at the lowest unit cost has always been our philosophy – a value our customers deserve."

BucklingBeam's vertical area array and copper pillar MEMS-based Motus III SD probe card goes above and beyond the competition by exceeding high-performance requirements. It also provides a substantial product life enhancement necessary to keep the cost of testing as low as possible. Once the probe tips become worn after extended use, customers can simply remove the SD for more than double the probe extension with no special training or service required. Most importantly, the mechanical probe performance characteristics do not change when the SD is removed, and the probe card can be re-used if the probe head ever requires rebuilding.

BucklingBeam's revolutionary Motus III MEMS SD technology features:

- Improved yield

- No probe sticking and high current delivery resulting in improved uptime

- More than two times extended probe contact life

- Easy risk-free maintenance