Jan 25 2016

Computer chips have been built using a photolithographic process since the 1960s. In the past five years however, chip features have become smaller than the wavelength of light, which has resulted in modifications of photolithography. If the miniaturization rate continues — as predicted by Moore’s Law — new manufacturing techniques need to be established.

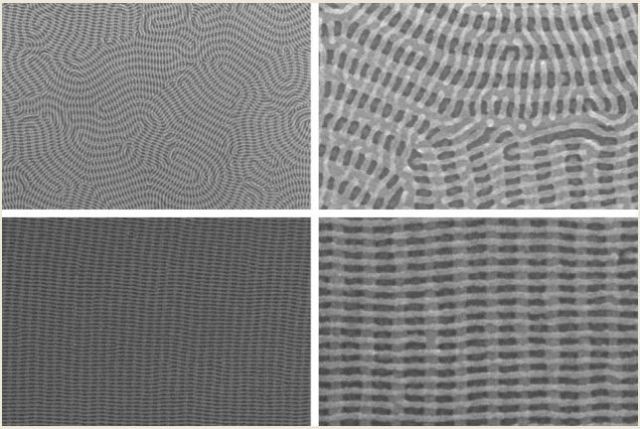

On the top row are two images of a nanomesh bilayer of PDMS cylinders in which the top layer is perpendicular to the complex orientation of the bottom layer. The bottom images show well-ordered nanomesh patterns of PDMS cylinders. The images on the right show zoomed-in views of the images on the left. Courtesy of the researchers

On the top row are two images of a nanomesh bilayer of PDMS cylinders in which the top layer is perpendicular to the complex orientation of the bottom layer. The bottom images show well-ordered nanomesh patterns of PDMS cylinders. The images on the right show zoomed-in views of the images on the left. Courtesy of the researchers

Block copolymers - molecules that can spontaneously self-assemble into many useful shapes - are a promising alternative to photolithographic processes. In a paper published in Nature Communications, MIT researchers discuss the first technique for assembling layers of block-copolymer wires so that the wires of one layer naturally orient perpendicularly to those in the layer below.

The “mesh structures” formed could make self-assembly a more practical method to produce memory, optical chips, and advanced versions of computer processors.

There is previous work on fabricating a mesh structure — for example our work. We used posts that we had fabricated by electron-beam lithography, which is time consuming. But here, we don’t use the electron-beam lithography. We use the first layer of block copolymer as a template to self-assemble another layer of block copolymer on top of it.

Amir Tavakkoli, Postdoctor, MIT’s Research Laboratory of Electronics

Tavakkoli’s co-first-authors on the paper are Sam Nicaise, a graduate student in electrical engineering, and Karim Gadelrab, a graduate student in materials science and engineering. The senior authors are Alfredo Alexander-Katz, the Walter Henry Gale Associate Professor of Materials Science and Engineering; Caroline Ross, the Toyota Professor of Materials Science and Engineering; and Karl Berggren, a professor of electrical engineering.

Polymers are long molecules made from basic molecular units present in a chain form. Plastics are polymers, as are biological molecules like proteins and DNA. A copolymer is a polymer that is made by linking two different polymers.

The constituent polymers are chosen so they are chemically incompatible in a block copolymer. In their attempts to move away from each other - within a single polymer chain and also in a polymer film - they self-organize.

In the study, one set of polymers is carbon-based and the other is silicon-based. In an attempt to move away from the carbon-based polymers, the silicon-based polymers fold in on themselves to form cylinders with loops of silicon-based polymer on the inner side, and the other polymer on the outer side. When the looped-cylinders are exposed to oxygen plasma, the carbon-based polymer is burnt away while the silicon oxidizes, resulting in glass-like cylinders joined to a base.

The process is repeated to assemble another layer of cylinders, although the copolymers have a different chain length this time. The cylinders in the newly formed layer are oriented perpendicular to those in the previous one.

When the surface where the first group of cylinders are formed is chemically treated, the cylinders line up in parallel rows. The second layer of cylinders also form parallel rows and are perpendicular to those in the first.

If the cylinders in a bottom layer are formed haphazardly and in looping patterns, cylinders in the second layer will keep their relative orientation, creating elaborate, but perpendicular patterns.

The orderly mesh structure has many applications, but the disorderly one is a more impressive technical achievement. “That’s the one the materials scientists are excited about,” Nicaise says.

For electronic applications, glass-like wires are not directly useful, but it is possible to implant them with other molecules to make them electronically active, or use them as a model to deposit other materials. The researchers feel that the results can be reproduced with more functional polymers. For this purpose, the process which yielded the results had to be theoretically characterized.

We use computer simulations to understand the key parameters controlling the polymer orientation.

Karim Gadelrab, Graduate Student

They found that the geometry of the bottom layer cylinders restricted the orientations of the top layer cylinders. If the lower cylinder walls are too steep to allow the upper cylinders a comfortable fit, the upper cylinders take a different orientation.

It is vital that the upper layer and lower layer have weak chemical interactions, to prevent the upper cylinders stacking themselves on top of the lower cylinders like a log pile.

Both cylinder geometry and chemical interaction can be determined from the physics of polymer molecules, so it is possible to recognize other polymers that present the same behavior.

According to Patrick Theofanis, an engineer at the chip manufacturer Intel, the spaces between the nanocylinders are more interesting than the cylinders themselves.

In general, the ability to pattern square holes is very useful for us. If you think of the back end of our chips, we have the back-end wiring, and then you have the interconnect layers between those back-end metal layers, and that’s where you’d like to be able to punch through holes and connect one layer to the next one. It’s an attractive technology because the aspect ratio is very tunable in the way that they’ve done their scheme.

Patrick Theofanis, Engineer, Intel

The research was funded by the Taiwan Semiconductor Manufacturing Corporation and the National Science Foundation.