Feb 4 2016

Karlsruhe Institute of Technology (KIT) scientists have developed the smallest-ever 3D lattice structure, measuring less than 200 nm in diameter and 1 µm in length. Their size is smaller by a factor of 5, in comparison with equivalent metamaterials.

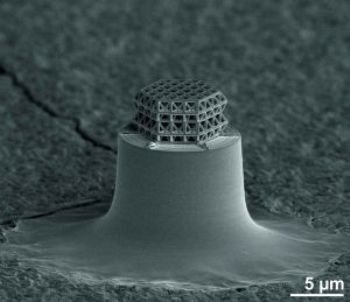

The smallest lattice in the world is visible under the microscope only. Struts and braces are 0.2 µm in diameter. Total size of the lattice is about 10 µm. (Photo: J. Bauer / KIT)

The smallest lattice in the world is visible under the microscope only. Struts and braces are 0.2 µm in diameter. Total size of the lattice is about 10 µm. (Photo: J. Bauer / KIT)

The researchers have reported their work in the journal, Nature Materials.

The struts and braces of the lattice structure are made out of glassy carbon. They exhibit unprecedented strength-to-density ratios due to their miniature size. The possible applications of the 3D lattice structure include filters, electrodes or optical components.

Lightweight construction materials, such as bones and wood, are found everywhere in nature. They have a high load-bearing capacity and small weight and, hence, serve as models for mechanical metamaterials for technical applications.

Dr.-Ing. Jens Bauer, Karlsruhe Institute of Technology (KIT)“

Metamaterials with structures of micrometer (millionth of a meter) dimensions are specifically planned and fabricated to have optical or mechanical properties, which cannot be realized by unstructured solids. Examples of metamaterials include; invisibility cloaks, which guide heat, light or sound around objects, and which counterintuitively response to shear and pressure (auxetic materials), or light-weight nanomaterials having high specific stability (force per unit area and density).

The smallest-ever stable lattice structure developed was initially produced by the well-known 3D laser lithography process. The micrometer-sized structure is hardened by computer-controlled laser beams in a photoresist. Since this process has limited resolution, only struts measuring 5-10 µm in length and 1 µm in diameter can be fabricated. Pyrolysis technique was subsequently used to shrink and vitrify the structure. This is the first time that pyrolysis had been employed for producing microstructured lattices. The structure is then exposed to about 900°C in a vacuum furnace, resulting in reorientation of chemical bonds. All elements, barring carbon, escape from the photoresist. The unordered carbon - as glassy carbon - is retained in the structure. The researchers tested the final structures to determine whether they were stable under pressure.

According to the results, load-bearing capacity of the lattice is very close to the theoretical limit and far above that of unstructured glassy carbon. Diamond is the only solid having a higher specific stability.

Professor Oliver Kraft, Co-Author

Microstructured materials are frequently utilized for shock absorption or insulation. In the chemical industry, open-pored materials are used as filters. Metamaterials also possess unusual optical properties, useful for telecommunication applications. Glassy carbon, an advanced material made up of pure carbon, has both graphite properties as well as glassy, ceramic properties. Possible applications of glassy carbon include electrodes of electrolysis systems or batteries.