May 2 2017

Unlimited possibilities are almost available for the new field of two-dimensional, one-atomic-layer-thick materials, including but not limited to graphene. Penn State material scientists, in their new research, report two discoveries that will offer an effective and simple way to "stencil" superior quality 2D materials in precise locations and also to overcome a hurdle that prevents their usage in next-generation electronics.

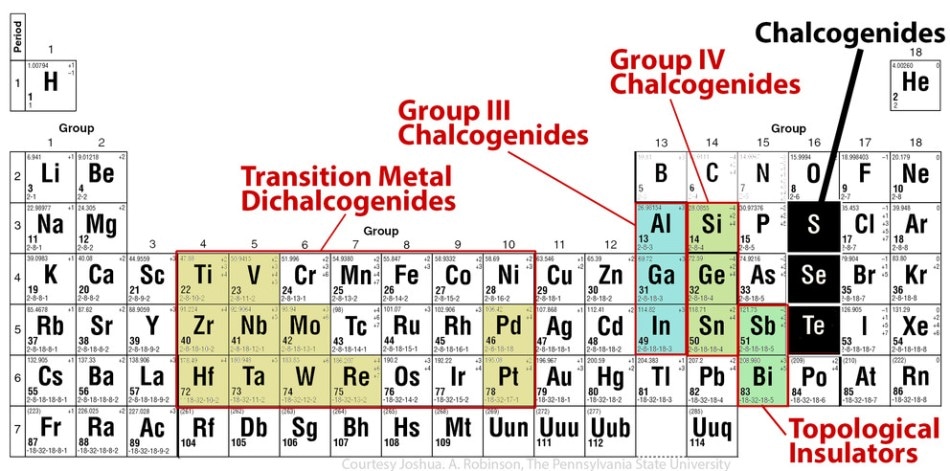

The Periodic Table highlighting the Chalcogenide families of elements. Image: Joshua Robinson / Penn State

The Periodic Table highlighting the Chalcogenide families of elements. Image: Joshua Robinson / Penn State

The discovery of a method to isolate a single atomic layer of carbon — graphene — in 2004, opened a new world of 2D materials comprising of properties not essentially present in the well-known 3D world. Transition metals, also known as a large group of elements, are present among these materials. These metals fall in the middle of the periodic table. A three-layer sandwich called a transition metal dichalcogenide is obtained when atoms of particular transition metals, for instance molybdenum, are layered between two layers of atoms from the chalcogenide elements, such as selenium or sulfur. TMDs have developed remarkable interest among materials scientists due to their potential for new types of computation, optoelectronics and electronics.

What we have focused on in this paper is the ability to make these materials over large areas of a substrate in precisely the places we want them. These materials are of interest for a variety of next-generation electronics, not necessarily to replace silicon, but to augment current technologies and ultimately to bring new chip functionality to silicon that we never had before.

Joshua Robinson, associate professor of materials science and engineerin

Chip companies will need to develop a method to accurately place the atoms where they are needed in order to incorporate TMDs with silicon in transistors. This method has not been developed till date. In their 2D Materials paper, "Selective-area Growth and Controlled Substrate Coupling of Transition Metal Dichalcogenides," Robinson and his group, for the very first time, demonstrated a simple method for producing precise patterns of two-dimensional materials employing techniques common to any nanotechnology lab.

"It turns out the process is straight forward. We spin photoresist on the sample in the cleanroom, as if we are going to start making a device. It can be any of a number of polymers that are used in nanofabrication. We then expose it to ultraviolet light in the desired areas, and we develop it like a photograph. Where the polymer was exposed to light, it washes away, and we then clean the surface further with standard plasma-etching processes. The 2D materials will only grow in the areas that have been cleaned.

Robinson

This work describes a second simple discovery that could help in enhancing the field of TMD research. This discovery refers to the aspect of overcoming the powerful effect a substrate has on the 2D materials grown on top of the substrate. In this case, a highly studied semiconductor TMD, called molybdenum disulfide, was grown on a sapphire substrate using typical powder-based deposition techniques. This resulted in the properties of the sapphire/molybdenum disulfide interface controlling the preferred properties of the molybdenum disulfide, thus making it unsuitable for device fabrication.

We needed to decouple the effects of the substrate on the 2D layer without transferring the layers off the sapphire and so we simply tried dunking the as-grown material into liquid nitrogen and pulling it out into air to 'crack' the interface. It turned out that was enough to separate the molybdenum disulfide from the sapphire and get closer to the intrinsic performance of the molybdenum disulfide.

Robinson

The process is considered to be gentle enough in order to weaken the bonds connecting the 2D material to the substrate without entirely setting it free. Robinson stated that the precise mechanism for loosening the bonds is yet be discovered and still under investigation, due to the complexity of this simple process. Both the materials shrink at varied rates, which may cause them to pop apart, however, this could also be due to the bubbling of the liquid nitrogen as it transforms into gas, or even come in contact with water vapor in the air that produces ice on the sample.

We're still working on understanding the exact mechanism, but we know that it works really well, at least with molybdenum disulfide.

Robinson

Doctoral students Brian Bersch and Yu-Chuan Lin, and research associate Sarah Eichfeld are the three co-lead authors on the paper. Robinson's doctoral student Keohao Zhang and his former doctoral student, Ganesh Bhimanapati, now at Intel, undergraduate student Aleksander Piasecki, and Materials Research Institute staff scientist Michael Labella also contributed to this work. Robinson is co-director of the Center for Atomically Thin Multifunctional Coatings and the Center for Two-Dimensional and Layered Materials, and director of user programs for the Penn State 2D Crystal Consortium, all part of the Penn State Materials Research Institute.

The Center for Low Energy Systems Technology, one of six Semiconductor Research STARnet centers of the Semiconductor Research Corporation; the Defense Threat Reduction Agency; and the National Science Foundation supported the research.