May 17 2019

Researchers at Rice University’s Brown School of Engineering have invented a nanocomposite that promises to be an excellent high-temperature dielectric material for flexible electronics, electric devices, and energy storage.

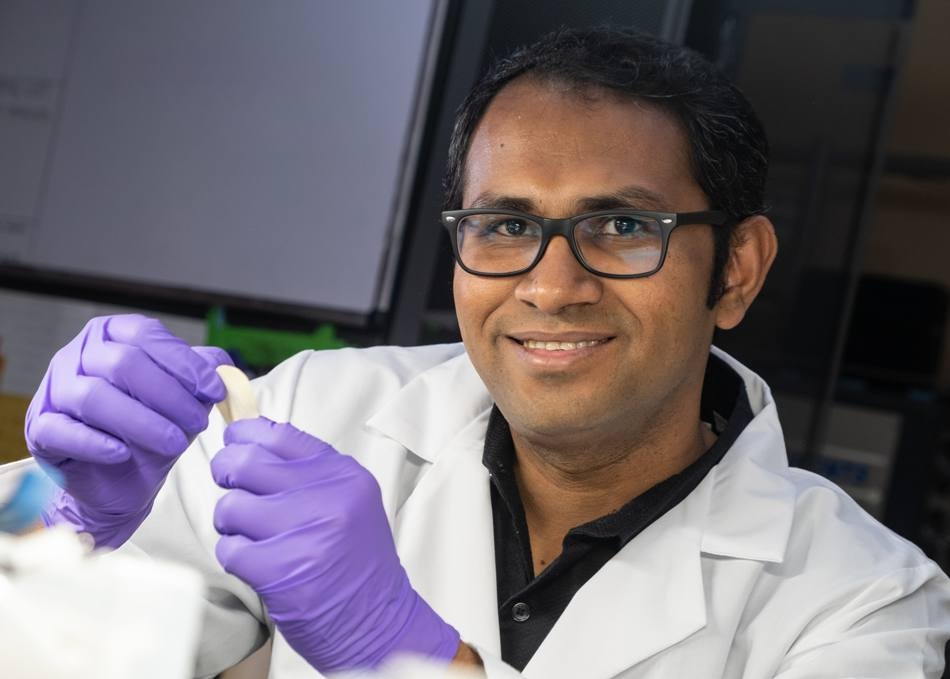

Rice research scientist M.M. Rahman holds a flexible dielectric made of a polymer nanofiber layer and boron nitride. The new material stands up to high temperatures and could be ideal for flexible electronics, energy storage and electric devices where heat is a factor. (Image credit: by Jeff Fitlow)

Rice research scientist M.M. Rahman holds a flexible dielectric made of a polymer nanofiber layer and boron nitride. The new material stands up to high temperatures and could be ideal for flexible electronics, energy storage and electric devices where heat is a factor. (Image credit: by Jeff Fitlow)

The nanocomposite integrates two-dimensional boron nitride nanosheets and one-dimensional polymer nanofibers. The nanofibers strengthen the self-assembling material while the “white graphene” nanosheets offer a thermally conductive network that enables it to endure the heat that breaks down typical dielectrics, the polarized insulators in batteries, and other devices that divide positive and negative electrodes.

The discovery by the lab of Rice materials scientist Pulickel Ajayan is illustrated in Advanced Functional Materials.

Research scientist M.M. Rahman and postdoctoral researcher Anand Puthirath of the Ajayan lab led the study to find a solution for the challenge posed by next-generation electronics: Dielectrics must be thin, flexible, tough, and able to endure harsh surroundings.

“Ceramic is a very good dielectric, but it is mechanically brittle,” Rahman said of the common material. “On the other hand, polymer is a good dielectric with good mechanical properties, but its thermal tolerance is very low.”

Boron nitride is an electrical insulator, but favorably disperses heat, he said. “When we combined the polymer nanofiber with boron nitride, we got a material that’s mechanically exceptional, and thermally and chemically very stable,” Rahman said.

The 12-to-15-micron-thick material serves as an effective heat sink up to 250 °C (482 °F), according to the scientists. Tests revealed the polymer nanofibers-boron nitride combination distributed heat four times better than the just the polymer alone.

In its most basic form, a single layer of polyaramid nanofibers binds via van der Waals forces to a sprinkling of boron nitride flakes, 10% by weight of the end product. The flakes are sufficiently dense to develop a heat-dissipating network that still permits the composite to keep its flexibility, and even foldability, while preserving its robustness. Layering polyaramid and boron nitride would make the material thicker while still preserving flexibility, according to the scientists.

The 1D polyaramid nanofiber has many interesting properties except thermal conductivity,” Rahman said. “And boron nitride is a very interesting 2D material right now. They both have different independent properties, but when they are together, they make something very unique.

M.M. Rahman, Research Scientist, Rice University

The material is scalable and can be easily integrated into manufacturing, according to Rahman.

Co-authors of the research paper are Rice academic visitors Aparna Adumbumkulath and Fanshu Yuan, alumnus Thierry Tsafack, graduate students Morgan Barnes, Zixing Wang, Sandhya Susarla, Seyed Mohammad Sajadi, Devashish Salpekar and Hossein Robatjazi, research scientist Ganguli Babu and Rafael Verduzco, an associate professor of chemical and biomolecular engineering and of materials science and nanoengineering; Sampath Kommandur and Shannon Yee of the Georgia Institute of Technology; and Kazuki Nomoto, S.M. Islam and Huili Xing of Cornell University. Ajayan is chair of Rice’s Department of Materials Science and NanoEngineering, the Benjamin M. and Mary Greenwood Anderson Professor in Engineering and a professor of chemistry.

The research was funded by the Army Research Laboratory.

Heat transfer in fiber-reinforced nanocomposite

A lab video shows how quickly heat disperses from a composite of a polymer nanoscale fiber layer and boron nitride nanosheets. When exposed to light, both materials heat up, but the plain polymer nanofiber layer on the left retains the heat far longer than the composite at right. (Courtesy of the Ajayan Research Group)