The findings indicate that all-solid-state batteries and silicon-based fuel cells are likely to be the future generation of EV internal battery packs with greater specific power and improved safety characteristics.

Reduction in Greenhouse Gas Emission using EVs

One of the primary causes of rising temperatures and climate destruction is the release of greenhouse gases (GHGs) from carbon fuels. The automobile industry makes up about 14% of global GHG emissions from fossil fuels.

Many governments have pledged to cut emissions from their transport industries worldwide.

One of the most effective and realistic techniques to reduce GHG emissions is to replace traditional internal combustion engine (ICE) automobiles with electric and hybrid vehicles. According to reports, if all ICE cars were converted to EVs and their recharging energy was derived entirely from clean energy sources, a country's GHG emissions could be cut by 40%.

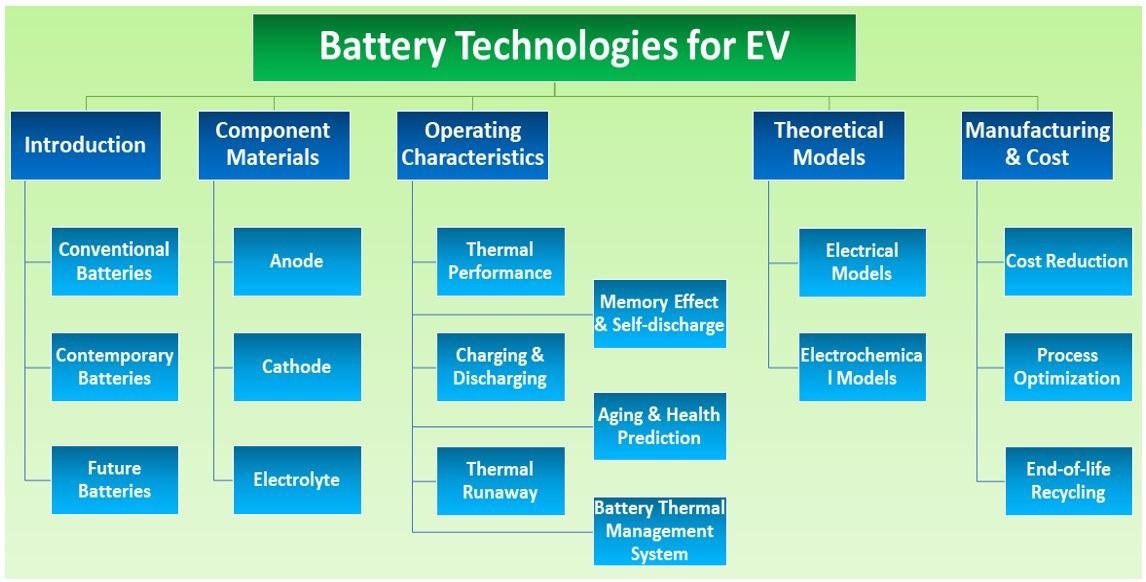

An overview of the contents of this research. © Zhao, G. et al. (2022)

Batteries for Electric Vehicles

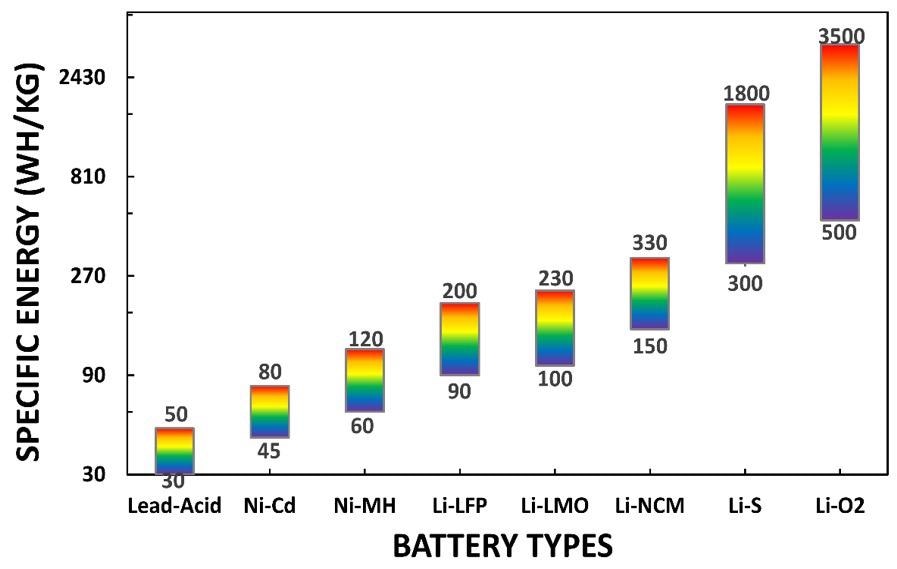

Previously, lead-acid and nickel-based battery packs were the most commonly used cells for electric vehicles.

The current EV battery industry is dominated by lithium-ion batteries. Meanwhile, potential alternatives such as hydrophilic or solid electrolyte (SE) battery packs, LiO2 fuel cells, Li-S batteries, and ASSBs are being developed as the next generation of EV batteries.

Optimal battery chemistry, on the other hand, is tough to obtain. Different anode, cathode, and electrolyte materials have various advantages and disadvantages under different operating situations. Furthermore, due to global supply and uncertain demand dynamics, raw material costs vary wildly.

Market Potential of EV batteries

The future growth of the battery industry will need multidisciplinary talents and initiatives.

The procedures for exploring improved electrodes, electrolytes, and separation materials to produce better-integrated power battery packs are being studied to improve the chemical characteristics of batteries, their morphological structures, and electrical capabilities.

On the other hand, as the EV sector expands, battery technology will flourish to keep up with the rapid speed of this exciting automotive electrification transition.

Electric cars are expected to account for around 70% of vehicle sales in Europe by 2040, implying an enormous yearly demand of 1200 gigawatt-hours, requiring a $150 billion investment. The business's prospective revenues are so high that neither veterans nor newcomers would pass up this rich customer base.

Anode, Cathode, and Electrolyte Materials

Graphite provides better properties and great cycling stability as an economically feasible and technically sound anode material. Still, its potential power density is lower than that of other new anode materials such as lithium-metal anodes and Si-based anodes.

Si-based anodes have good specific capacitance and cycle efficiency at reasonable prices, but their significant breathing impact and capacity degradation issues restrict their industrial use.

Even though LFP is universally acknowledged as a great cathode material because of its robustness, long cycle duration, excellent thermal conductivity and reliability, and cheap production cost, some OEMs choose greater specific power and lower self-discharge rate devices. This is because high power density does not always imply high risk.

During the manufacturing and engineering processes, any ignorance or disregard for current safety regulations might create disqualified battery cells. Therefore, great care is needed during the production of EVs' cathode materials.

The specific energy values of some mainstream and future EV batteries. © Zhao, G. et al. (2022)

Conclusions and Prospects

In the short term, Li-ion battery packs, such as NCM, LMO, and LFP, will continue to dominate the on-board rechargeable battery pack market because of their outstanding qualities, including good specific energy, no memory impact, minimal self-discharge, and extended cyclic stability. However, once ASSB, Si-based anode cells, and Li-S battery packs are more thermostable, technologically trustworthy, and commercially rewarding, they will be the next-generation commercial electric vehicle fuel cells.

Aside from the never-ending quest for greater battery specific strength and power, Zn-ion and Na-ion batteries hold great promise as less expensive and safer alternatives to Li-ion batteries, providing a decent compromise between capabilities and expense due to their abundant crust storage, whereas the market price of Li has been rising in tandem with the growing market for Li-ion fuel cells.

Continue reading: Where does Nanotechnology fit in Electrification?

Reference

Zhao, G. et al. (2022). Connecting Battery Technologies for Electric Vehicles from Battery Materials to Management. iScience. Available at: https://www.sciencedirect.com/science/article/pii/S2589004222000141

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.