Polyurea is an elastomeric material with remarkable mechanical characteristics. However, pure polyurea elastomers are often hampered by a lack of toughness and performance.

What are Polyurea Materials?

Polyurea is one of the most important materials for structural impact absorption. Its soft sections are mostly composed of long carbon sequences, oligomeric polyols, and other elastic sections with a wide range of conformations. Isocyanates and chain extenders are used as mechanical crosslinks and strengthening phases in the hard sections.

Polyurea has distinct viscoelastic characteristics that are substantially affected by pressure, heat, and strain rates. The robust hydrogen bonding and intricate internal structures contribute to its remarkable defensive features.

Polyurea polymers are restricted in certain situations owing to a lack of practicality or poor protective effectiveness. The nanocomposite technique could help to address these problems.

Functional Conductive Additives: The Future of Polymers

Functionalized polymer-based substances typically integrate polymers with particular functional additives to generate new or significantly improved capabilities such as conductance, heat dissipation, barrier properties, and detection, particularly self-sensing, which is required for information-based advanced materials.

Fiber optics are often used to provide sensing capabilities to polymeric materials or concrete composites. This, in turn, causes faults in the composites and necessitates the use of large-scale testing equipment. Self-sensing nanomaterials, which have appeared in recent years, are anticipated to overcome this constraint.

Under external stress, the conducting particle-matrix distorts and breaks away, enabling the network to alter and the composites' electrical resistance (the piezo-resistive capability) to change.

Graphene Nanoplatelets (GNPs) as Functional Additives

Metals (e.g., flakes or strands), conducting foams, MXenes, and activated carbon fillers like carbon black, nanotubes, and graphene nanoplatelets (GNPs) are all good considerations for conductive additives.

Metal-based compounds have the drawback of being heavier due to their large loadings. Higher loadings can result in a decrease in machinability and a rise in expenses.

GNPs have gained popularity because of their superior electromechanical qualities. Efficient conducting networks may be built at low electric percolation criteria due to their large aspect ratios. However, the homogeneous distribution of GNPs in polymeric materials remains a significant challenge.

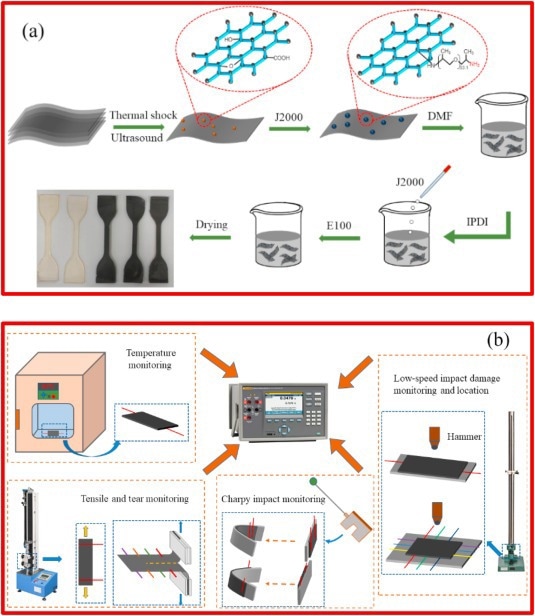

Schematics for (a) preparation of a polyurea/F-GNP nanocomposite and (b) the multi-channel sensing system. © Meng, Q. et al. (2022)

Highlights of the Current Research

While most prior polyurea research focused only on mechanical characteristics and capabilities, the present work focuses on the multi-functionality of polyurea nanomaterials.

Functionalized graphene nanoplatelets (F-GNPs) were employed as fiber reinforcements in this study to create multifaceted, self-sensing polyurea composite materials with improved mechanical performance.

The researchers looked into the effect of F-GNPs on the mechanical characteristics and impact strength of polyurea elastomers to see whether the nanocomposites might be extensively employed as protective substances.

Key Findings of the Study

Polyurea nanocomposites, as a novel type of multifunctional nanomaterials, not only offer continuous and secure strain detecting and temperature measurement properties, but they can also monitor and pinpoint the progression of their degradation, as shown by low-speed impact and tearing experiments.

The electric conduction of all produced nanocomposites increased as the nanofiller concentration increased, and the electric percolation limit was determined to be 1.05 vol percent. The nanocomposite demonstrated remarkable sensibility in the strain region of 0–5%.

The findings reveal that the standardized resistance of the nanocomposite changes with temperature, and its sensitivities varies between the low and high-temperature ranges. The nanocomposites showed good reliability and stability during cycling strain measurements up to 9100 cycles and exhibited a steady sensing capacity between 20°C and 80°C.

Future Outlook and Prospects

This study describes a straightforward and efficient method for producing high-efficiency, multifaceted polyurea nanocomposites. These functionalities are realized by the modification, degradation, and restoration of the conducting system inside the nanomaterials.

The self-sensing capacity of functionalized polyurea composites to correctly detect and pinpoint blast damage and crack development as a new category of smart materials may open the door to numerous new industrial applications.

Reference

Meng, Q. et al. (2022). Smart multifunctional elastomeric nanocomposite materials containing graphene nanoplatelets. Smart Materials in Manufacturing. Available at: https://Researchers Reveal the Multifunctionality of Polyurea Nanocomposites

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.