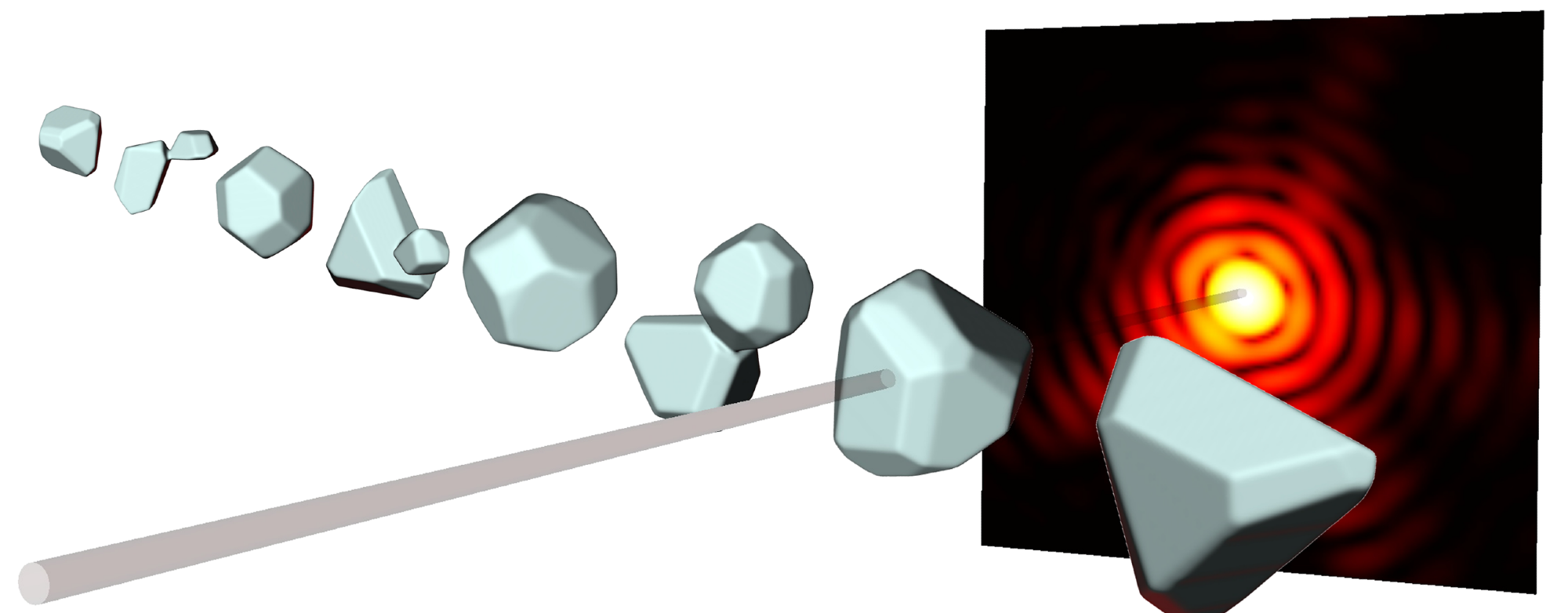

From the diffraction patterns (red) of X-Ray pulses (grey), with which nanoparticles are bombarded, researchers at ETH can calculate three-dimensional images. Image Credit: ETH Zürich / Daniela Rupp

Using this method, short-wavelength X-Ray beams are blasted at the object being studied. The interference between the diffracted beams causes distinctive diffraction patterns, which can be utilized to determine an object’s shape.

With the help of very short, incredibly powerful X-Ray pulses, it has been able to analyze even single nanoparticles. In most cases, though, this simply produces a two-dimensional representation of the particle.

The three-dimensional structure of a particle can now be calculated from a single diffraction pattern, allowing one to “look” at the particle from all angles, according to a team of researchers led by ETH professor Daniela Rupp and including members from the universities of Rostock and Freiburg, the TU Berlin, and DESY in Hamburg.

Future developments should potentially make it feasible to record the dynamics of nanostructures in 3D. The scientific journal Science Advances published the study’s findings.

Since 2019, Daniela Rupp has served as an assistant professor at ETH Zurich, where she is the group leader for the research group “Nanostructures and ultra-fast X-ray science.”

With the support of her group, she aims to better understand how matter interacts with extremely powerful X-Ray pulses. They employ nanoparticles as a model system, which they also study at the Paul Scherrer Institute.

For the future there are great opportunities at the new Maloja instrument, on which we were the first user group to make measurements at the beginning of last year. Right now, our team there is activating the attosecond mode, with which we can even observe the dynamics of electrons.

Daniela Rupp, Assistant Professor, Department of Physics, ETH Zurich

A Deeper View into Dynamical Processes

According to postdoctoral researcher Alessandro Colombo, the recently published study represents a significant step toward that future.

With this work, we open a window on studies of dynamical processes of the extremely small particles in the femtosecond regime.

Alessandro Colombo, Postdoctoral Researcher, ETH Zurich

The issue with employing extremely intense pulses for X-Ray diffraction involves the fact that the objects under study rapidly disappear after the bombardment, or “diffract and destroy,” according to the researchers. It makes sense that one would want to extract as much information as possible from the nanoparticle, as this restricts the number of snapshots that can be taken of it.

Up until now, one had to impose certain severely restricting assumptions on the shape of the nanoparticle on the computer algorithm to calculate more than a 2D image from the diffraction pattern.

This keeps any smaller aspect of the particle that deviates from those presumptions secret, though. Also, numerous tweaks using these algorithms had to be done by hand.

Improved Algorithm

Rupp added, “This is where our new method comes in. With our new algorithm, which uses a very efficient simulation method and a clever optimization strategy, we can automatically produce 3D images of the nanoparticle without having to impose specific requirements. This allows us to see even tiny irregularities, which can arise from the growth process of the particle.”

To obtain a 3D resolution, the ETH researchers employ not just the part of the diffraction pattern that is diffracted by a small angle of a few degrees, as was previously done, but also the wide-angle part of 30 degrees or more. Of course, this means that the amount of information to be retrieved grows exponentially, but the new algorithm can handle this increase.

Rupp’s team can now calculate 3D images of the particles from various angles using the diffraction patterns of single silver nanoparticles, 70 nm in size, which are hit with X-Ray pulses lasting roughly 100 femtoseconds.

Snapshots in Free Flight

Rupp further added, “Up to now we were missing that third dimension but now we can investigate many processes either for the first time or with unprecedented precision, for instance, how nanoparticles melt in a few picoseconds or how nanorods accumulate to form larger objects.”

The key element is that the snapshots can be captured in free flight in a vacuum rather than having to anchor the nanoparticles on a surface, as in electron microscopy. Moreover, many particles cannot even be placed on a surface because they are too fragile or have a short lifetime.

Even samples that can be investigated with an electron microscope are influenced significantly by their interaction with the surface. Melting or aggregation processes, on the other hand, can be examined in free flight without any disruption.

Journal Reference

Colombo, A., et al. (2023) Three-dimensional femtosecond snapshots of isolated faceted nanostructures. Science Advances. doi:10.1126/sciadv.ade5839.