When cornstarch and water are combined in the proper amounts, a substance that seems neither liquid nor solid is formed. When left alone, oobleck flows and settles like a liquid, then stiffens when scooped up or swirled with a spoon. Scientists have long battled to explain why the characteristics of oobleck and other non-Newtonian fluids, such as Silly Putty, quicksand, paint, and yogurt, change under stress or strain.

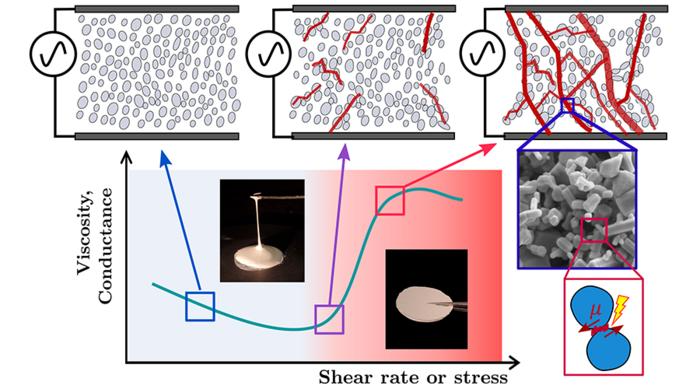

As a dense suspension of piezoelectric nanoparticles shear thickens due to a transition from frictionless (gray) to frictional (red) particle–particle interactions, friction-induced piezoelectricity in the contacting particles generates electric charge, which in turn increases the AC conductance of the surrounding fluid. Image Credit: Kim et al.

As a dense suspension of piezoelectric nanoparticles shear thickens due to a transition from frictionless (gray) to frictional (red) particle–particle interactions, friction-induced piezoelectricity in the contacting particles generates electric charge, which in turn increases the AC conductance of the surrounding fluid. Image Credit: Kim et al.

Researchers at the University of Chicago’s Pritzker School of Molecular Engineering (PME) have investigated the fundamental physics of non-Newtonian fluids using piezoelectric nanoparticles, which vary in reaction to pressure. Friction between particles was determined to have an important role in causing the materials to transition from a fluid to a more solid form.

This not only answers long-standing basic questions about the physical origins of these materials but opens up doors for the design of new non-Newtonian fluids with practical applications.

Stuart Rowan, Study Co-Senior Author and Barry L. MacLean Professor, Molecular Engineering, University of Chicago

The study was published in the Proceedings of the National Academy of Sciences.

Paint that does not clump, liquids that solidify into a mold when shaken, and wearable safety gear that stiffens when impacted are just a few of the possible uses.

Piezoelectric Probes

The viscosity, or thickness, of non-Newtonian fluids is characterized by a sharp shift when the materials are stressed. This means that for certain materials, stress causes thinning. Ketchup can be made much more pourable by shaking the bottle; toothpaste, yogurt, and mayonnaise all keep their shape in a container but become more liquid-like when used.

However, certain materials react the opposite way, such as oobleck, a concentrated particle suspension, which can seem solid when handled but collapse into a puddle when set down.

Scientists have developed suggestions to explain why dense particle suspensions change when sheared—when subjected to numerous forces operating in opposite directions. These assumptions primarily concern how the molecules and particles that comprise the materials can interact with one another in various ways under different situations—yet each theory is difficult to verify.

To understand these concentrated particle suspensions, we want to be able to look at the nanoscale structure, but the particles are so incredibly crowded together that imaging these structures is very hard.

Hojin Kim, Study First Author and Postdoctoral Researcher, University of Chicago

Kim worked with Rowan, Aaron Esser-Kahn, a professor in the PME and an expert in piezochemistry, and Heinrich Jaeger, the Sewell Avery Distinguished Service Professor of Physics, to solve this difficulty. The team devised a method for measuring the change in electrical conductance as a function of shear stress. The nanoparticle was then suspended in a liquid at such a concentration that it displayed non-Newtonian behavior similar to oobleck.

The liquid’s top and bottom were subjected to shear stress, and the researchers simultaneously recorded the changes in viscosity and electrical impulses that resulted. This enabled them to ascertain the nature of the particle interactions as the material transitioned from a more liquid to a more solid state.

Kim added, “We found that friction between particles was critical to this transition. In this concentrated particle solution, there is a tipping point when the friction reaches a certain level and the viscosity abruptly increases.”

A Range of Applications

Comprehending the fundamental principles governing a concentrated particle solution is a necessary first step toward developing novel non-Newtonian fluids in the laboratory. Scientists might one day be able to alter the viscosity of these synthesized substances through stress because of their customizable features.

This can, in some cases, result in reduced clumping and clogging of liquids, such as paint and concrete. In other circumstances, it might refer to the deliberate hardening of materials as needed.

“For any application, we hope we can eventually determine the ideal combination of solvents and particles and shear conditions to get the properties we want. This paper might seem like very fundamental research but in reality, non-Newtonian fluids are everywhere and so this has a lot of applications,” Kim stated.

For the time being, the researchers from Pritzker Molecular Engineering and the University of Chicago intend to use the stress-induced piezoelectric activity of their nanoparticle suspensions to create novel materials that are sensitive and adaptable, such as those that stiffen in response to mechanical force.

Journal Reference:

Kim, H., et al. (2023). Stress-activated friction in sheared suspensions probed with piezoelectric nanoparticles. Proceedings of the National Academy of Sciences. doi:10.1073/pnas.2310088120.