Researchers from Utrecht University, Harvard Department of Chemistry & Chemical Biology, and Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) have reported on a previously obscure method to enhance the selectivity of catalytic reactions.

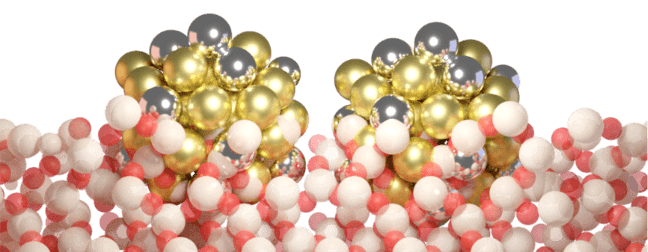

Nanoparticles with smaller average interparticle distance. Gold, silver, white and red spheres represent gold, palladium, Silicon and oxygen atoms, respectively. Image Credit: Aizenberg Lab/Harvard SEAS

Nanoparticles with smaller average interparticle distance. Gold, silver, white and red spheres represent gold, palladium, Silicon and oxygen atoms, respectively. Image Credit: Aizenberg Lab/Harvard SEAS

The study, which was published in Nature Catalysis, adds to the arsenal of ways to increase the efficiency of catalysts for a possible broad spectrum of applications in various industries, such as cosmetics and pharmaceuticals.

The chemical industry relies on catalysts for more than 90% of its operations, and almost all of these catalysts are made up of nanoparticles scattered on top of a substrate. Researchers have long believed that the size of individual nanoparticles and the distance between them influence the speed of the catalytic reaction and the products produced. Still, since nanoparticles are susceptible to moving around and agglomerating during catalysis, it has been difficult to study exactly how.

Over the last decade, Joanna Aizenberg, the Amy Smith Berylson Professor of Materials Science and Professor of Chemistry & Chemical Biology, and her team have drawn inspiration from nature to create highly organized, porous materials for a wide range of catalytic processes.

Inspired by the structure of butterfly wings, the researchers created a new catalyst platform that slightly embeds nanoparticles into the substrate, capturing them so they do not move around during catalysis while leaving the rest of the nanoparticles’ surface exposed, allowing them to undergo catalytic reactions effectively and without agglomeration.

The researchers discovered that the distance between particles significantly impacted the reaction’s selectivity.

Many industrially-relevant chemical reactions follow a cascade whereby chemical A is turned to chemical B which can then be turned into chemical C and so forth. In some catalytic processes, the intermediate chemical, chemical B, is the goal, while in others it is the end product, chemical C. The selectivity of the catalyst refers to whether it favors the production of chemical B or chemical C.

Kang Rui Garrick Lim, Study First Author and Graduate Student, John A. Paulson School of Engineering and Applied Sciences, Harvard University

A notable example is the manufacturing of benzyl alcohol, which is used in everything from shellac, paints, and leather to intravenous drugs, cosmetics, and topical treatments.

Benzyl alcohol is the intermediate chemical B produced by the hydrogenation of benzaldehyde (chemical A), which precedes the formation of toluene (chemical C), another extensively used but less valuable molecule. To effectively create benzyl alcohol, the creation of toluene must be prevented.

Currently, the catalytic hydrogenation reaction is slowed down, or not conducted to conclusion, to ensure that the reaction will halt at B and create as little toluene as possible, leading to the more usable benzyl alcohol.

Lim added, “Generally, to make these intermediate chemicals, you make the catalyst less reactive and the overall reaction slower, which is not productive at all. Catalysts are meant to speed things up, not slow them down. Catalysts are meant to speed things up, not slow them down.”

The researchers used the catalytic synthesis of benzyl alcohol to illustrate their platform. Lim and colleagues discovered that the reaction was more specific to the intermediate molecule, benzyl alcohol when catalytic metal nanoparticles were positioned further apart on the substrate. The final product, toluene, was the target of the reaction, more so when the nanoparticles were closer together.

The research indicates that the bioinspired catalyst platform could be easily modified for a variety of intermediate or end-product chemicals since the spacing between nanoparticles can be artificially altered.

Catalysis is central to production of a whole range of extremely important materials that are used in pharmaceuticals, consumer products and in manufacturing many products all of us use in everyday life. Adding this selectivity-improving tool to the chemist’s arsenal is extremely important. It will allow more effective tuning of catalytic processes, more economical use of the feedstocks accompanied by the reduction of energy consumption and waste generation. We hope that chemists will use our platform in further optimization of new and existing catalytic processes.

Joanna Aizenberg, Amy Smith Berylson Professor of Materials Science and Professor of Chemistry & Chemical Biology, Harvard University

The group will then employ the same platform to investigate how the size of the nanoparticles affects the response at predetermined nanoparticle distances from one another.

The underlying technology for this research is from Professor Aizenberg’s lab, and its intellectual property is protected by Harvard’s Office of Technology Development.

Michael Aizenberg, Marta Perxes Perich, and Jessi E. S. van der Hoeven, Sadhya Garg, Haichao Wu, and Selina K. Kaiser co-authored the study.

It was partially funded by the US Defense Threat Reduction Agency (DTRA) under award number HDTR1211001612 and the US Department of Energy, Office of Science, Basic Energy Sciences, through the Integrated Mesoscale Architectures for Sustainable Catalysis (IMASC) Energy Frontier Research Center.

Journal Reference:

Lim, K. R. G., et. al. (2024) Nanoparticle proximity controls selectivity in benzaldehyde hydrogenation. Nature Catalysis. doi:10.1038/s41929-023-01104-1