Learn about the recent studies that have advanced carbon nanotube (CNT) fabrication.

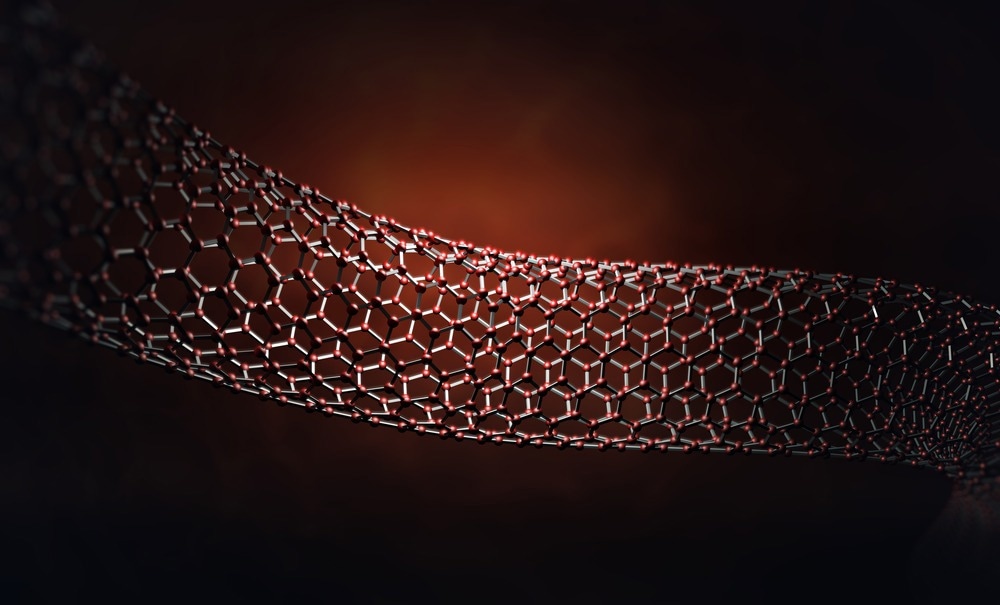

Image Credit: Mopic/Shutterstock.com

Introduction

Carbon nanotubes (CNTs) are cylindrical structures formed by carbon atoms arranged in a hexagonal lattice, and display distinctive traits that render them well-suited for a diverse array of applications.1

CNTs are categorized as either single-walled (SWCNTs) or multi-walled (MWCNTs), depending on the number of concentric cylinders they possess. SWCNTs exhibit remarkable electrical conductivity, whereas MWCNTs boast superior mechanical strength. These distinctive attributes have prompted their utilization across diverse domains, including electronics, materials science, medicine, and energy storage. CNTs are actively applied in creating lightweight and durable materials, conductive films, sensors, and drug delivery systems, underscoring their adaptability and capacity to bring about transformative changes in various industries.2

Different Fabrication Methods of CNTs

Various techniques are utilized to fabricate carbon nanotubes, each possessing its own advantages and limitations. Among the most prevalent methods are chemical vapor deposition (CVD), arc discharge, laser ablation, and chemical processes such as the Solvothermal method. CVD is extensively employed for achieving controlled growth, while arc discharge and laser ablation are recognized for generating high-quality CNTs in large quantities. Chemical methods stand out for their simplicity and scalability, rendering them well-suited for extensive production. The selection of a fabrication method hinges on the intended application and the specific properties desired for the carbon nanotubes.3

Challenges to Carbon Nanotube Fabrication

While carbon nanotubes hold tremendous promise, fabricating them is plagued by various challenges. The attainment of high purity and uniformity in CNTs proves to be a persistent challenge, with the presence of impurities and structural defects posing a threat to their inherent properties. Another obstacle is the control of chirality, referring to the arrangement of carbon atoms during growth, as it profoundly impacts the electronic properties of the nanotubes. Furthermore, the substantial challenge of scaling up production while simultaneously ensuring cost-effectiveness hinders the widespread commercial adoption of carbon nanotubes. Addressing these challenges is crucial to unlocking the full potential of this groundbreaking nanomaterial.4

Recent Studies in Carbon Nanotube Fabrication

In a recent study, B. Cui et al. (2023) introduced a novel approach by incorporating copper (Cu) catalysts in the process of growing CNTs on the surface of continuous carbon fiber (CF). Their study aimed to investigate the impact of Cu catalyst on the properties of the resulting CNT-CF composite. The findings of the study suggest that the innovative use of Cu catalyst in the growth of CNTs on CF surfaces results in a composite material with enhanced tensile strength and interfacial shear strength.

The proposed "loading-catalysis–reinforcing" mechanism provides a theoretical foundation for optimizing catalytic systems and encourages the exploration of more novel catalyst options for the development of advanced CNT-CF composites.5

In another study, D. Yang et al. (2021) synthesized cobalt phosphide (CoP) nanoparticles supported within a network of nitrogen-doped carbon nanotubes (N-CNTs) using a spray-drying method followed by thermal treatments. Their objective is to investigate the electrocatalytic performance of the resulting material in the hydrogen evolution reaction (HER) and oxygen evolution reaction (OER) during water splitting. The findings of the study suggest that the synthesized system is a promising strategy for efficient water splitting.

Incorporating the N-doped CNT conductive network enhances the catalytic activity by promoting charge transfer, reducing particle size, and enlarging the active area. When employed as cathode and anode, the material demonstrates excellent overall water-splitting performance with low voltage and extended stability, making it a potentially valuable candidate for scalable and cost-efficient electrocatalysts in energy conversion applications.6

Furthermore, Shah et al. (2021) developed nanocomposites by dispersing Al2O3 powders and graphene in a suspension of carbon nanotubes (CNTs) in ethanol. After milling for 4 hours, the powders were sintered using Spark Plasma Sintering (SPS) in a vacuum at 1500 °C with a constant uniaxial pressure of 21 MPa. Their study demonstrated the fabrication of nanocomposites by dispersing Al2O3 powders and graphene in a CNT suspension.

The increase in graphene content affected the density, dispersion, and mechanical properties of the composite. The toughening effect was attributed to improved densification between graphene and CNTs at the interface. The incorporation of graphene impacted the thermal properties, leading to a slight reduction in thermal conductivity; however, at lower concentrations, graphene exhibited minimal influence. The findings provide insights into the fabrication and properties of graphene-enhanced Al2O3/CNT nanocomposites, highlighting both mechanical and thermal characteristics for potential applications in diverse fields.7

At last, X. Liang et al. (2020) studied to develop a stable and biocompatible conductive ink suitable for fabricating flexible and wearable electronics. The ink was created by combining CNTs with natural silk sericin. Experimental investigations were conducted to understand the structural changes and interactions in the sericin-CNT hybrid. Molecular dynamics studies were employed to elucidate the non-covalent interactions, particularly those between the aromatic groups of sericin and CNTs, contributing to the stability of the dispersion.8

Their findings found that the ink exhibited remarkable electrical conductivity, stability but also good biocompatibility with human cells. The versatility of the ink in various fabrication techniques and its compatibility with diverse, flexible substrates suggest its potential for applications in wearable electronics. The demonstrated proofs of concept, including ECG sensors and breath sensors, emphasize the promising role of sericin-CNT (SSCNT) ink in advancing human-friendly wearable devices for health monitoring and other applications.8

Conclusion

The progress in fabricating carbon nanotubes presents significant potential for transforming diverse industries. Examining the general overview of CNTs and their applications, coupled with an exploration of various fabrication methods, underscores the multifaceted character of this state-of-the-art technology.

Although challenges exist in attaining high purity and scalable production, recent studies embracing innovative approaches like catalyst engineering, continuous flow synthesis, and the integration of graphene with CNTs offer promising avenues to overcome these obstacles. These advancements hold the key to unlocking the complete potential of carbon nanotubes in the foreseeable future.

References and Further Reading

Rathinavel, S.,et al. (2021). A review on carbon nanotube: An overview of synthesis, properties, functionalization, characterization, and the application. Materials Science and Engineering: A, B 268, p.115095.

Ibrahim, K. S. (2013). Carbon nanotubes-properties and applications: a review. Carbon Letters. 14, pp.131–144.

Rahman, G. et al. (2019). An Overview of the Recent Progress in the Synthesis and Applications of Carbon Nanotubes. C 5, p.3.

Sengupta, J. (2018). Carbon Nanotube Fabrication at Industrial Scale. Elsevier eBooks, pp.172–194. doi.org/10.1016/B978-0-12-813351-4.00010-9.

Cui, B. et al. (2023). In‐situ growth of bamboo‐like carbon nanotubes from Cu catalyst on continuous carbon fibre for interfacial enhancement. Composites Science and Technology, 234, p.109933.

Yang, D., et al. (2021). Cobalt phosphide nanoparticles supported within network of N-doped carbon nanotubes as a multifunctional and scalable electrocatalyst for water splitting. Journal of Energy Chemistry, 52, pp.130–138.

Shah, W. A., et al. (2021). Toughness enhancement and thermal properties of graphene-CNTs reinforced Al2O3 ceramic hybrid nanocomposites. Chemical Physics Letters, 781, p.138978.

Liang, X. et al. (2020). Stable and Biocompatible Carbon Nanotube Ink Mediated by Silk Protein for Printed Electronics. Advanced Materials, 32, p.2000165.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.