Sep 21 2009

WACKER, the Munich-based chemical company, will be using the 24th European Photovoltaic Solar Energy Conference (EU PVSEC) to present several new products for the solar industry. One of the interesting new developments is TECTOSIL®, a plastic film designed especially for the encapsulation of photovoltaic modules. It is made out of a thermoplastic silicone elastomer that is pliable when heated, making it fast and easy to process. In addition, WACKER will showcase new silicones for PV applications from its ELASTOSIL® Solar product line. Examples include the UV-activated encapsulant, ELASTOSIL® Solar 2120 UV, as well as the two-component silicone, ELASTOSIL® Solar 3210, developed especially for high-concentration photovoltaic systems. The 24th European Photovoltaic Solar Energy Conference will take place from September 21–24 in Hamburg, Germany.

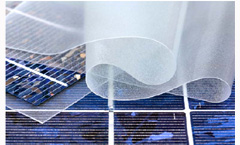

TECTOSIL® is an innovative material from WACKER for encapsulating photo-voltaic modules. The sheet is a silicone-based thermoplastic. Transparent and non-yellowing, this material helps achieve high module efficiency and provides lasting protection of all solar module types. (Photo: Wacker Chemie AG)

TECTOSIL® is an innovative material from WACKER for encapsulating photo-voltaic modules. The sheet is a silicone-based thermoplastic. Transparent and non-yellowing, this material helps achieve high module efficiency and provides lasting protection of all solar module types. (Photo: Wacker Chemie AG)

As a leading producer of hyperpure polycrystalline silicon, WACKER has been an important partner of the solar industry for many years now. Alongside polysilicon, WACKER’s silicones play an important role in the manufacture of PV modules, whether as potting compounds, adhesives and sealants, or encapsulants for solar cells. Because of its specially-designed PV products and comprehensive expertise in silicones, the chemical company has established itself as an important pacesetter for the entire PV industry, particularly when innovative and efficiency-boosting materials for solar module production are needed.

WACKER will continue to demonstrate its innovative strength at the 24th EU PVSEC in Hamburg, where it will present several highlights from its product portfolio. For example, it will premiere the innovative encapsulant, TECTOSIL®. TECTOSIL® is a flexible, highly trans-parent and electrically insulating sheet comprising a silicone-organo copolymer. Because of its thermoplastic properties, this silicone-based polymer can be processed quickly and inexpensively – without curing or chemical reactions.

This is what sets TECTOSIL® apart from conventional encapsulants. The lamination process thus benefits from short production cycles and a high tolerance to local temperature differences within the laminator. TECTOSIL® sheets help to lower manufacturing costs and ensure that modules are produced in consistently high quality.

Solar cells encapsulated in TECTOSIL® are afforded optimum protection against mechanical and chemical stresses. The material bonds the components of a PV module into a stable laminate. Since it is highly elastic and extremely flexible across a very large temperature range, TECTOSIL® can compensate the different thermal expansions of the laminate materials. In this way, TECTOSIL® ensures that the solar cells are encapsu-lated without stress.

The novel polymer also has the advantage of being chemically stable, which means there is no risk of clouding, yellowing or the like. The sheet does not contain catalysts or corrosive substances. On contact with moisture, it does not produce any substances that might initiate corrosion or damage surfaces. That allows the sheet to be used for encapsulating solar cells containing films of compound semiconductors (e.g. copper indium gallium diselenide or cadmium telluride), or other highly sensitive chemical substances – such as transparent conduc-tive oxides. The material absorbs hardly any water at all, poses an effective moisture barrier and stays permanently electrically insulating. Thanks to the unique properties of TECTOSIL®, modules can produced with high quality and a long service life.

TECTOSIL® is a non-reactive, easy-to-handle material. It does not need to be cooled during transportation and storage. Modules prod-uced with the new encapsulant have passed all the tests required by IEC 61215. The material can be used to make any type of module and is suitable for either vacuum laminators or continuous processes. As a result, TECTOSIL® paves the way for new processing techniques.

ELASTOSIL® Solar: Customized Silicones for the Solar Industry

Among the new ELASTOSIL® Solar products is ELASTOSIL® Solar 2120 UV encapsulant. This is a UV-activated silicone elastomer that cures at room temperature without any additional heat. The trick here is that UV light triggers the crosslinking process. Curing of the silicone encapsulant at room temperature – until now a time-consuming process – is effected in just a few minutes.

WACKER now offers this innovative curing technology, which was first used successfully in its SEMICOSIL® UV series, in a silicone elastomer formulated specifically for the solar industry. The advan-tage of ELASTOSIL® Solar 2120 UV over conventional, high-tem-perature curing systems is its very short curing time which can be customized within a broad time frame and processing window. Thicknesses of several centimeters can be cured. Unlike epoxy- or acrylate-based UV-curing polymers, ELASTOSIL® Solar 2120 UV contains no photoinitiators. It therefore leaves neither ions nor free-radical decomposition products in the material.

ELASTOSIL® Solar 2120 UV is particularly suitable for encapsulating junction boxes. The translucent product is electrically insulating, resistant to weathering and UV radiation, and of low viscosity. The cured compound has a hardness of 40 Shore 00.

ELASTOSIL® Solar 3210 for High-Concentration PV Systems

High-concentration photovoltaic (HCPV) systems are an alternative to the conventional PV technology used in photovoltaic power plants. HCPV systems employ special lenses that concentrate sunlight and focus it onto high-performance cells. Much higher efficiencies are achieved in this way than with the usual solar modules.

WACKER has developed ELASTOSIL® Solar 3210 specifically for these high-performance modules. The two-part rubber is pourable and is characterized by very good light permeability (transmission). It is thus ideally suited for the production of optical lenses and moldings, for example Fresnel lenses. ELASTOSIL® Solar 3210 cures fast and does not shrink, is easily demolded and shows high dimensional stability. It is of medium hardness (approx. 45 Shore) and, like all ELASTOSIL® Solar grades, is electrically insulating and resistant to weathering and UV.