Nov 24 2010

Easy-to-use nano-coating sprays with optical, electronic, biological properties, etc to cover surfaces! Teams from the Institut Charles Sadron (CNRS / Université de Strasbourg), in collaboration with researchers from the Laboratoire de Biomatériaux et Ingénierie Tissulaire (Inserm / Université de Strasbourg), have managed to improve and extend their technique of “layer by layer” deposition.

This scientific synergy has led to the development of a very wide range of nano-coatings with new and varied applications that will doubtless be of great interest to industry. Their work was published online on 23 November 2010 on the site of the journal Angewandte Chemie International Edition.

Novel method of depositing nano-materials in the form of thin films.

Novel method of depositing nano-materials in the form of thin films.

Contact lenses, cars, non-stick saucepans or stickers: numerous objects in our daily lives have coatings with specific functions. Over fifteen years ago, Gero Decher invented a novel method of depositing nano-materials in the form of thin films. The principle of this technique simply consists in “stacking”, with nanometric precision, layers whose structure and chemical functionalities are controlled by the sequence and nature of the constituents incorporated in the film (polymers, pigments, proteins, particles, etc.). This “layer-by-layer” method makes it possible to produce materials with extremely varied properties. Neither costly nor polluting, this process ranks among the ten most important results in chemistry over the last decade.

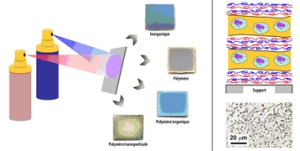

Recently, teams of chemists and physical chemistry specialists, headed by Gero Decher and Pierre Schaaf of the Institut Charles Sadron (CNRS/Université de Strasbourg), in collaboration with Jean-Claude Voegel’s team from the Laboratoire de Biomatériaux et Ingénierie Tissulaire (Inserm/Université de Strasbourg), have recently succeeded in making this deposition method even more powerful and easy to apply. Initially, the technique required successive dippings in different liquids and long deposition times. Now, using two bottles, the scientists can simultaneously spray two liquids on a surface to be coated. Time saving and logistical advantages are considerable.

Better still, this original method applies to a whole range of nano-coatings, including completely new classes of materials, such as purely inorganic films. The already wide range of applications of these thin films has therefore been further extended. The nano-coatings obtained by these various deposition methods have many applications in materials science: light emitting diodes, fuel cells, photovoltaic cells, anti-corrosion coatings, flexible screens, separation membranes, etc. Furthermore, the introduction of biologically active molecules (peptides, enzymes, medicines, proteins, DNA, cells, etc.) within these films makes it possible to obtain nano-coatings that have numerous applications in life sciences: biocompatibility of implants, preparation of dressings, tissue engineering, gene transfection, pharmaceutical vectors, bio-sensors, etc. This host of applications is likely to meet industry's objectives to cut production costs, invest in sustainable product development and extend product ranges. In short, this innovative nano-assembly method makes it possible to envisage the elaboration of a large number of (bio)-materials or products that do not yet exist.

Source: http://www.cnrs.fr/