Researchers from Lawrence Berkeley National Laboratory, University of California (UC), Berkeley, and Rice University have produced boron nitride nanoribbons using a method in which boron nitride nanotubes are embedded with potassium atoms until the tubes dissect longitudinally. These nanoribbons are expected to exhibit excellent magnetic and electronic properties that hold high prospects for future devices.

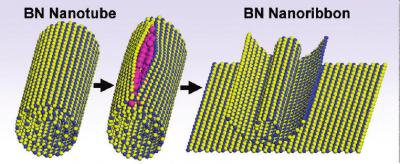

Splitting of a boron nitride nanotube

Splitting of a boron nitride nanotube

Nanoribbons are 2D single crystals of one atom thickness measuring several µm in length and in width nearly hundred or less nm. Pure carbon Graphene nanoribbons, transfer electrons at speeds quicker than silicon, and are capable of covering wide areas and a broad variety of shapes. Boron nitride nanoribbons provide same advantages as graphene nanoribbons together with added range of optical, magnetic, and electronic properties that benefit spintronics and optoelectronics technologies.

Zettl and his research team inserted atoms or molecules of one type between atoms and molecules of another type. This chemical process is called intercalation. James Tour and his team at Rice University intercalated potassium atoms into carbon nanotubes causing the tubes to split longitudinally. This led to the collaboration of Zettl and Tour to apply the same approach to boron nitride nanotubes that are similar in structure to carbon nanotubes.

Zettl stated that the principle behind the splitting process of carbon and boron nitride nanotubes is that potassium islands start to grow at the beginning point of intercalation. This island continues to grow till it causes a split in the chemical bonds of the intercalated nanotube. The potassium stimulates further breakage by bonding to the bare ribbon edge.

Edges are crucial to a nanoribbon’s properties because the electrons in the edges of one ribbon can interact with the electrons in another ribbon edge, generating an energy gap that is apt for making devices.

This method produces boron nitride nanoribbons of uniform widths about 20 nm and one micron in length, with fewer defects along the edges or within the plane. Zettl says, high proportion boron nitride nanoribbons exhibit a coveted zigzag or armchair shaped edges.