Feb 13 2013

EPFL’s Institute of Microengineering has reached a remarkable 10.7% efficiency single-junction microcrystalline silicon solar cell, clearly surpassing the previous world record of 10.1% held by the Japanese company Kaneka Corporation since 1998. Such significant efficiency, independently certified by the Fraunhofer Institute for Solar Energy Systems (ISE CalLab PV Cells), was achieved in addition with less than 2 micrometers of photovoltaic active material.

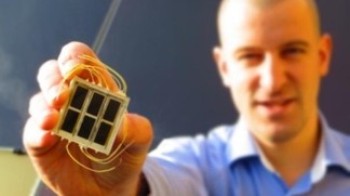

Record efficiency with less than 2 micrometers of silicium. © PVLab / EPFL

Record efficiency with less than 2 micrometers of silicium. © PVLab / EPFL

The Photovoltaics-Laboratory (PV-Lab) of IMT, founded in 1984 by Prof. Arvind Shah and now headed by Prof. Christophe Ballif, is well known as a pioneer in the development of thin-film silicon solar cells, and as a precursor in the use of microcrystalline silicon as a photoactive material in thin-film silicon photovoltaic (TF-Si PV) devices. A remarkable step was achieved this week by the team led by Dr. Fanny Meillaud and Dr. Matthieu Despeisse with a new world record efficiency of 10.7% for a single-junction microcrystalline silicon solar cell, independently confirmed at Fraunhofer Institute for Solar Energy Systems (ISE CalLab PV Cells), Freiburg, Germany.

“Deep understanding has been gained these last years in material quality, efficient light-trapping and cell design, which in combination with careful process optimization led to this remarkable world-record efficiency” says Simon Hänni, PhD student at IMT Neuchâtel. Importantly, the employed processes can be up-scaled to the module level. While standard wafer-based crystalline silicon PV technology implements absorber layers with a thickness of about 180 micrometers for module conversion efficiency of 15 to 20%, 10.7% efficiency was reached here with only 1.8 micrometers of silicon material, i.e. 100 times less material than for conventional technologies, and with cell fabrication temperature never exceeding 200°C. Thin-film silicon technology indeed offers the advantages of saving up on raw material and offering low energy payback time, thus allowing module production prices as low as 35 €/m2, reaching the price level of standard roof tiles.

The reported progress is of paramount importance for increasing further TF-Si PV devices efficiency and potential, as at least one microcrystalline silicon junction is systematically used in combination with an amorphous silicon junction to form multiple junction devices for a broader use of the solar spectrum. The reported record efficiency clearly indicates that the potential of TF-Si multi-junction devices can be extended to > 13.5% conversion efficiency with a minimum usage of abundant and non-toxic raw material at low costs (TF-Si PV modules implementing in their simplest form two glasses and few microns of zinc and of silicon for an easy recycling).

Work leading to this result was supported by the Swiss Federal Office of Energy (SFOE), the EU-FP7 program, the Swiss National Science Foundation (SNSF) and the Commission for Technology and Innovation (CTI).