Jan 5 2017

Rice University researchers claim that just a few nanoscale tweaks could enable graphene-nanotube junctions do extremely well at transferring heat. The Rice lab of theoretical physicist Boris Yakobson discovered that placing a cone-like “chimney” between the graphene and nanotube all but eliminates a barrier that hinders heat from escaping.

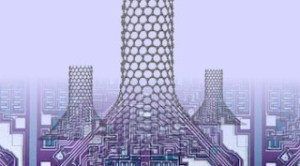

Simulations by Rice scientists show that placing cones between graphene and carbon nanotubes could enhance heat dissipation from nano-electronics. The nano-chimneys become better at conducting heat-carrying phonons by spreading out the number of heptagons required by the graphene-to-nanotube transition. (Illustration by Alex Kutana)

Simulations by Rice scientists show that placing cones between graphene and carbon nanotubes could enhance heat dissipation from nano-electronics. The nano-chimneys become better at conducting heat-carrying phonons by spreading out the number of heptagons required by the graphene-to-nanotube transition. (Illustration by Alex Kutana)

The research findings have been published in the American Chemical Society’s Journal of Physical Chemistry C.

Heat is transfered through phonons, quasiparticle waves that also convey sound. The Rice theory provides an approach to direct damaging heat away from next-generation nano-electronics.

Both graphene and carbon nanotubes contain six-atom rings, which produce a chicken-wire appearance, and both do extremely well at rapidly transferring electricity and phonons.

But when a nanotube grows from graphene, atoms aid the turn by developing heptagonal rings instead.

Researchers have established that forests of nanotubes grown from graphene are best for storing hydrogen for energy applications, however in electronics, the heptagons disperse phonons and block the dispersion of heat via the pillars.

The Rice researchers found out via computer simulations that removing atoms here and there from the 2D graphene base would compel a cone to develop between the graphene and the nanotube. The geometric properties of the graphene-to-cone and cone-to-nanotube transitions need the same total number of heptagons, but they are more lightly spaced and leave a clear path of hexagons available for heat to speed up the chimney.

Our interest in advancing new applications for low-dimensional carbon — fullerenes, nanotubes and graphene — is broad. One way is to use them as building blocks to fill three-dimensional spaces with different designs, creating anisotropic, nonuniform scaffolds with properties that none of the current bulk materials have. In this case, we studied a combination of nanotubes and graphene, connected by cones, motivated by seeing such shapes obtained in our colleagues’ experimental labs.

Yakobson

The researchers examined phonon conduction via simulations of pillared graphene, free-standing nanotubes, and nano-chimneys with a cone radius of either 20 or 40 Å. The pillared graphene was 20 % less conductive compared to plain nanotubes. The 20-Å nano-chimneys were as conductive as plain nanotubes. In contrast, 40-Å cones were 20 % better than the nanotubes.

The tunability of such structures is virtually limitless, stemming from the vast combinatorial possibilities of arranging the elementary modules. The actual challenge is to find the most useful structures given a vast number of possibilities and then make them in the lab reliably.

Alex Kutana, a Rice research scientist and co-author of the study.

“In the present case, the fine-tuning parameters could be cone shapes and radii, nanotube spacing, lengths and diameters. Interestingly, the nano-chimneys also act like thermal diodes, with heat flowing faster in one direction than the other,” he said.

The lead author of the paper is Rice graduate student Ziang Zhang. The co-author is Ajit Roy, a principal materials research engineer at the Air Force Research Laboratory in Dayton, Ohio. Yakobson is the Karl F. Hasselmann Professor of Materials Science and NanoEngineering and a professor of chemistry.

The Air Force Office of Scientific Research and its Multidisciplinary University Research Initiative provided assistance for this research. Calculations were performed on Rice’s National Science Foundation-supported DAVinCI supercomputer administered by the Center for Research Compting, procured in collaboration with the Ken Kennedy Institute for Information Technology. Simulated nano-chimneys developed by researchers at Rice University could assist in keeping next-generation nano-electronics cool by improving heat dissipation.