An article available recently as a pre-proof in the Journal of Materials Research and Technology demonstrated the viability of a printable conducting ink based on an aqueous emulsion for application in strain sensors and flexible electronic devices.

Study: Polylactic acid-Graphene Emulsion Ink based Conductive Cotton Fabrics. Image Credit: Rost9/Shutterstock.com

The Growing Demand for Biocompatible Wearable Electronics

Wearable technologies are rapidly becoming indispensable in the area of elastic electronic devices. As a result, there is an increasing desire for pliable, ultralight, easy-to-manufacture, low-cost, biologically compatible, and degradable electronic equipment.

Wearable elastic hybrid devices are extensively used for continual medical observation, diagnosis, and human-machine interactions, with research focusing on non-irritating and benign substances and inexpensive procedures.

Biocompatibility and biodegradability in functional electronic substances are critical properties for meeting numerous healthcare and environmental directives and minimizing the dangers connected with managing electronic waste. This is still the most challenging obstacle, and efforts are being made to address it via green electronics.

The Advantages of Using Bio-based Polymers

Bio-based substances such as hydrogels, regenerated silk, and polylactic acid (PLA) have the potential to revolutionize medical monitoring systems such as sensing devices and wearable electronics. Due to their biocompatible and environmentally friendly nature, sustainability, low expenses, and solution processability, bio-based polymers provide exciting possibilities for pliable electronic systems.

Conducting inks made from bio-based composites may be administered directly to any substrate through rod coating, spraying, or solution immersion. By producing a carbon enriched membrane on one of the sides of the films, the team was able to reduce electrical resistance by using bio-based carbon fillers.

At smaller quantities of bio-based carbon, this layer aids in the formation of the conducting system. The researchers discovered that, while the resultant deformations following tension did not fully repair due to the relaxed silk fibroin links, these substances are suitable for expendable ecologically friendly strain gauges.

Metallic nanoparticles and semiconducting metallic oxides, in addition to carbonaceous nanomaterials, are widely employed in pliable electronic devices. Despite substantial advances in recent times, their inherent mechanical qualities, considerable expenses, and questions about biological degradation and compatibility restrict their mainstream usage.

Finding the Right Solvent for the Job

The usage of toxic solvents must be reduced for bio-based polymeric materials to monopolize pliable electronics. This may be accomplished by employing halogen-free, biodegradable, and benign solvents for solution processing in electronic material synthesis. Recommendations for selecting a suitable solvent include high biopolymer solubility, minimal expenses, reduced risks, and reduced environmental effects.

Nonetheless, identifying a suitable ecologically benign solvent remains difficult. Stable PLA-based emulsions, such as oil-in-water, may be used to encapsulate functional electronic components like carbon nanofibers or graphene. Unfortunately, no prior research has been conducted on PLA-based emulsions employing green solvents to create electrically conducting inks.

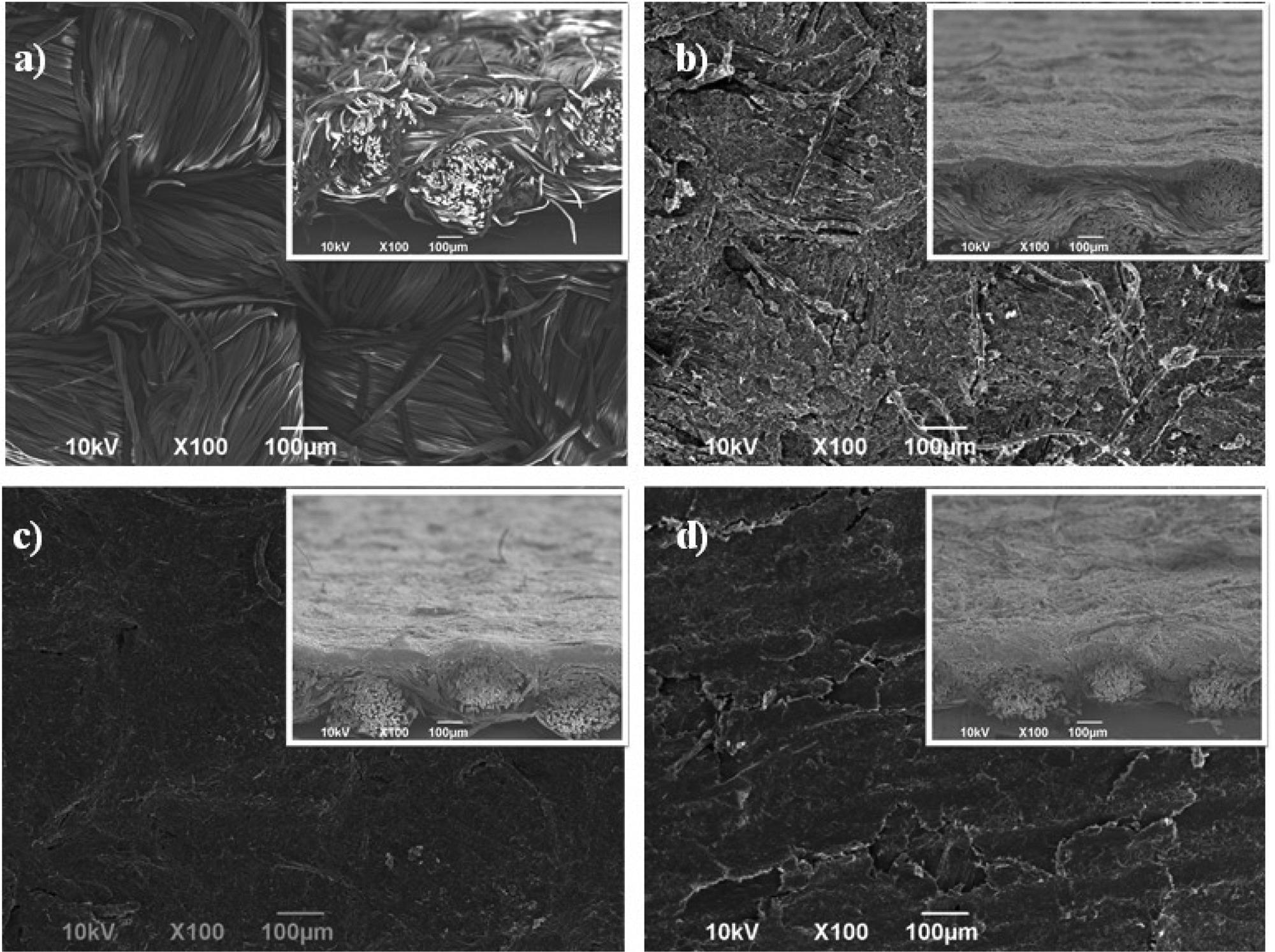

SEM images of the top-view of (a) pristine cotton fabric and samples coated with conductive inks, particularly, (b) sample PLA0.5, (c) PLA1.0 and (d) PLA1.5. No hot pressing is applied. The inset SEM images illustrate the cross-sectional view of the respective samples. © Najafi, M., Zahid, M., Ceseracciu, L., Safarpour, M., Athanassiou, A., & Bayer, I. S. (2022).

Developing a Biocompatible Conductive Ink

In this study, the researchers introduced an oil-water emulsion PLA-graphene-based printable conducting ink that may be utilized to develop functional coverings in consumer electronics and medical diagnostics. Water as well as biodegradable solvents, such as anisole, were used to create the emulsions. The inks were created by emulsification of various quantities of PLA as a binding agent. Inks were rod-coated over the textiles, reducing waste formation.

The emulsion and ink were studied using dynamic light scattering and an optical microscope. The results revealed a well-distributed oil-in-water emulsion containing scattered PLA and graphene nanoplatelets (GNPs).

Through the rod coating process, the inks were utilized to coat materials. Their morphological structure indicated that inks with a PLA:GnPs proportion of 1:1 coated the textiles the most uniformly, producing the greatest conductance and mechanical qualities when compared to the other inks created.

Conclusions

The findings indicated that the specimens' electric conductance was increased by a factor of two after being subjected to a hot press treatment. Moreover, the hot-pressed specimens demonstrated improved mechanical characteristics owing to greater PLA binder immersion into the weave.

Even after being subjected to several stretch-release rounds in strain tests, covered specimens maintained electric conductance. The breakdown of the conducting networks created by GnPs might account for the reduction in electric conductance reported towards the conclusion of the 100-cycle strain test. Printed inks were also resistant to abrasion and washing while retaining their conductance.

This environmentally friendly polymeric ink might be employed as a strain gauge in the conversion of some electronic modules to biodegradable equivalents.

Reference

Najafi, M., Zahid, M., Ceseracciu, L., Safarpour, M., Athanassiou, A., & Bayer, I. S. (2022). Polylactic acid-Graphene Emulsion Ink based Conductive Cotton Fabrics. Journal of Materials Research and Technology. Available at: https://www.sciencedirect.com/science/article/pii/S2238785422006202?via%3Dihub

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.