As far as engine parts are concerned, mineral oil lubricants help safeguard them from wear. This effect is improved by adding polymer nanoparticles to the lubricating oil.

Image Credit: Angewandte Chemie.

Currently, a research group from the UK team has found that epoxy functionalization of such nanoparticles additionally encourages friction reduction on metal surfaces.

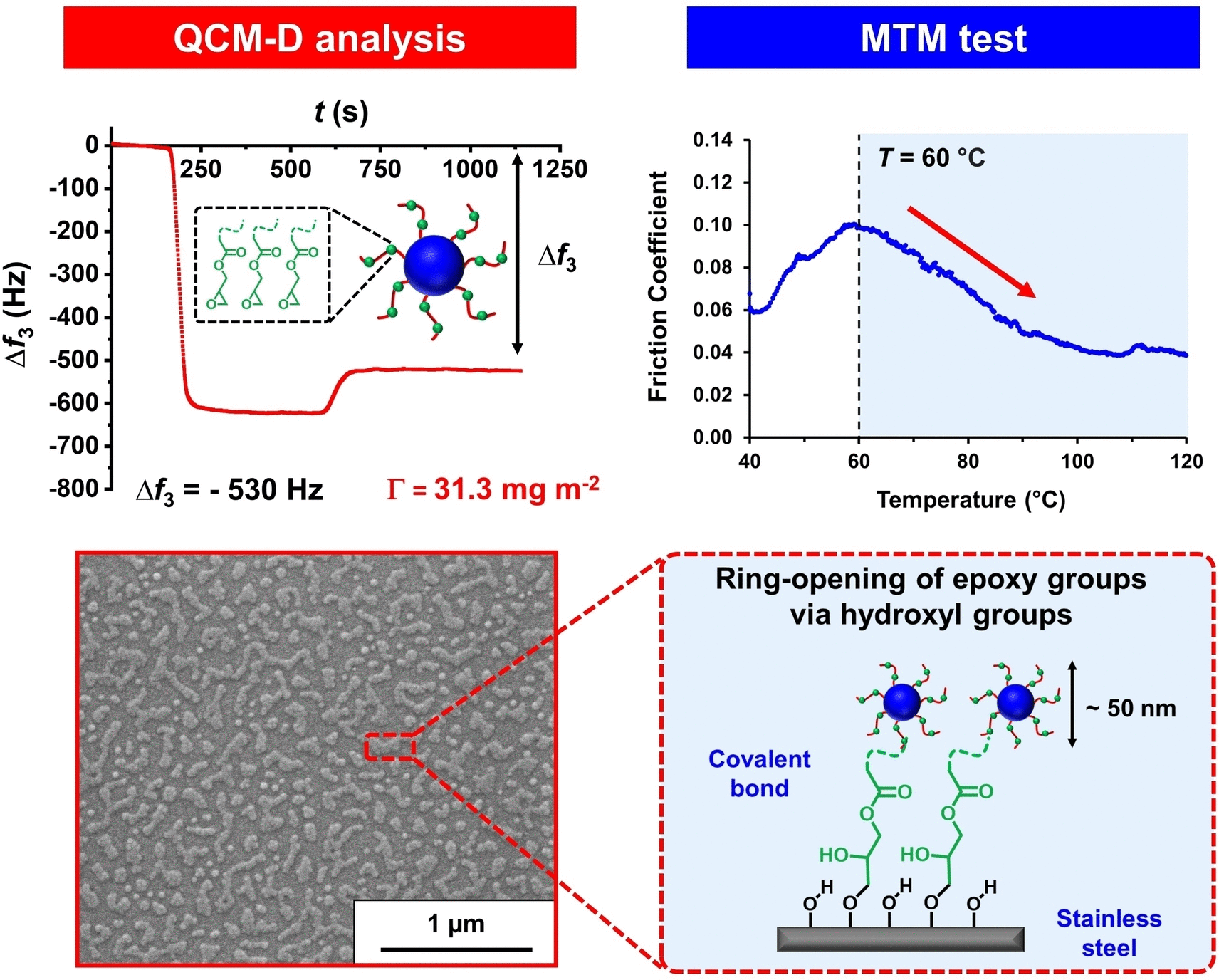

As reported by the team in the journal Angewandte Chemie, nanoparticles consisting of epoxy groups stick firmly to stainless steel surfaces, resulting in a considerable decrease in friction.

Automotive engines consisting of well-lubricated parts tend to use less fuel, produce lower emissions, and experience less long-term wear. Mineral oil has been extensively utilized as a lubricant, and nanoparticles could be made directly within this solvent by making use of a method called polymerization-induced self-assembly.

Coating the surface of the metal components with nanoparticles consisting of a few dozen millionths of a millimeter in size helps safeguard them from getting subjected to direct contact.

Csilla György and Steve Armes at the University of Sheffield (UK) developed “hairy” nanoparticles consisting of oil-soluble poly(lauryl methacrylate) chains and an oil-insoluble nanoparticulate core.

Such nanoparticles were made to stick firmly to metal surfaces by initiating epoxy groups into the “hairs” by copolymerizing lauryl methacrylate along with glycidyl methacrylate, an epoxy-functional monomer.

The research group found that the epoxy-bearing nanoparticles reacted with hydroxy groups situated at the surface of stainless steel. This reaction resulted in the powerful adhesion of the nanoparticles, a phenomenon called chemical adsorption; whether chemical adsorption happened or not relied on the accurate location of the epoxy groups.

To our surprise, introducing a far larger number of epoxy groups into the nanoparticle cores had no beneficial effect.

Steven P. Armes, University of Sheffield

The adsorbed nanoparticles helped decrease friction considerably, as the Sheffield team found while conducting tribological studies in partnership with researchers at Lubrizol, an engine oil additives company based in the United Kingdom (UK).

Remarkably, the adsorbed nanoparticles remained intact on the stainless steel surface after such experiments, which were conducted at the typical operating temperature of an internal combustion engine.

Steven P. Armes, University of Sheffield

Hence, such epoxy-functionalized nanoparticles could mean an additional leap in performance for lubricant additives for the next-generation engine oil formulations.

Journal Reference:

György, C., et al. (2023) Enhanced Adsorption of Epoxy-Functional Nanoparticles onto Stainless Steel Significantly Reduces Friction in Tribological Studies. Angewandte Chemie International Edition. doi.org/10.1002/anie.202218397.