Researchers from Osaka University, led by Professors Hidehiro Sakurai and Yumi Yakiyama, address the challenges of using standard laser sources in labs and propose the use of microchip laser (MCL) technology for PLAL experiments, enabling compact and cost-effective setups.

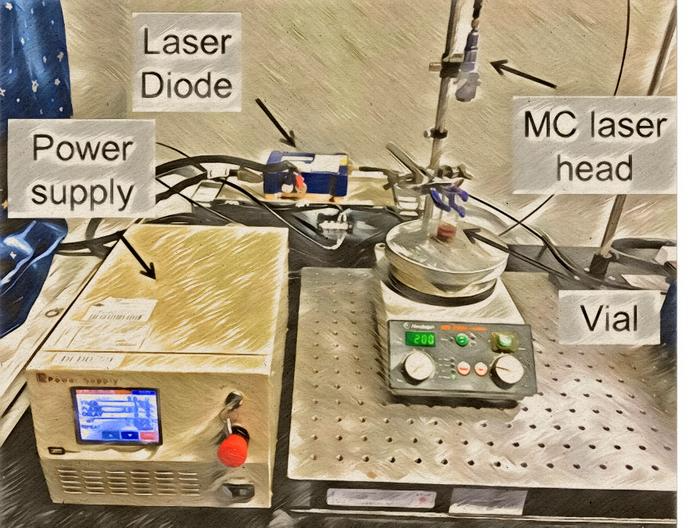

One of the setting examples for PLAL experiment in the organic synthetic lab. By using MCL, just less than half of the usual lab table space is needed. Image Credit: Yumi Yakiyama and Hidehiro Sakurai, Osaka University, Japan.

One of the setting examples for PLAL experiment in the organic synthetic lab. By using MCL, just less than half of the usual lab table space is needed. Image Credit: Yumi Yakiyama and Hidehiro Sakurai, Osaka University, Japan.

Metal nanoparticles (NPs) in solution can be produced with a dependable and adaptable method called pulsed laser ablation in liquid (PLAL). Its benefits over traditional metal NP preparation techniques like the chemical reduction method are the lack of reducing chemicals, ease of operation, high purity without purification processes, and ambient working settings.

The fact that PLAL is widely used in both industrial and scientific research domains attests to its value. However, standard laser sources are large and expensive, which presents an enormous challenge for labs, especially non-laser scientific ones.

Professors Hidehiro Sakurai and Yumi Yakiyama of Osaka University focused on the microchip laser (MCL) technology after realizing these obstacles. MCL is a small, low-power giant-pulse laser system with a short cavity length of less than 10 mm, developed by the Taira group at the Institute of Molecular Science (IMS).

This makes it a good fit for typical organic synthesis facilities. On January 5th, 2024, this study was published in the journal Industrial Chemistry & Materials.

Despite its benefit in compactness, the application of MCL’s parameters, particularly its low pulse energy, to PLAL of an Au target remained uncertain. The study team intended to explore how changes in instrumental specifications influence the outputs of Au PLAL, with the objective of improving benchtop synthesis and direct application of NPs for catalytic applications.

In their study, the researchers used MCL for Au PLAL, emphasizing the impacts of low laser pulse energy (0.5 mJ), short pulse length (0.9 ns), and low repetition rate (10 Hz) on ablation efficiency.

The results showed that MCL had reasonably good ablation efficiency while having a significantly lower pulse energy than traditional higher-power lasers (25 mJ/pulse, 12 ns duration, 10 Hz).

Our study provides new insights into the preparation of Au NPs using the compact MCL system. Importantly, it opens avenues for the direct use of highly reactive NPs prepared by MCL in the development of new catalytic reactions within standard synthetic chemistry laboratories.

Hidehiro Sakurai, Professor, Osaka University

Osaka University’s Barana Sandakelum Hettiarachchi, Yusuke Takaoka, Yuta Uetake, Yumi Yakiyama, and Mihoko Maruyama, Yusuke Mori, Hiroshi Y. Yoshikawa, and Hidehiro Sakurai, and the Institute of Molecular Science's Hwan Hong Lim and Takunori Taira make up the study team.

This study is supported by JSPS KAKENHI and the Amada Foundation for the Promotion of Science and Engineering.

Journal Reference:

Hettiarachchi, B. S., et. al. (2024) Uncovering gold nanoparticle synthesis using a microchip laser system through pulsed laser ablation in aqueous solution. Industrial Chemistry & Materials. doi:10.1039/D3IM00090G.

Source:

Industrial Chemistry & Materials