A new review published in the International Journal of Extreme Manufacturing describes a more powerful method for producing ultra-clean, customizable nanoparticles, advancing artificial sensory systems and human-machine interfaces.

Image Credit: Georgy Shafeev/Shutterstock.com

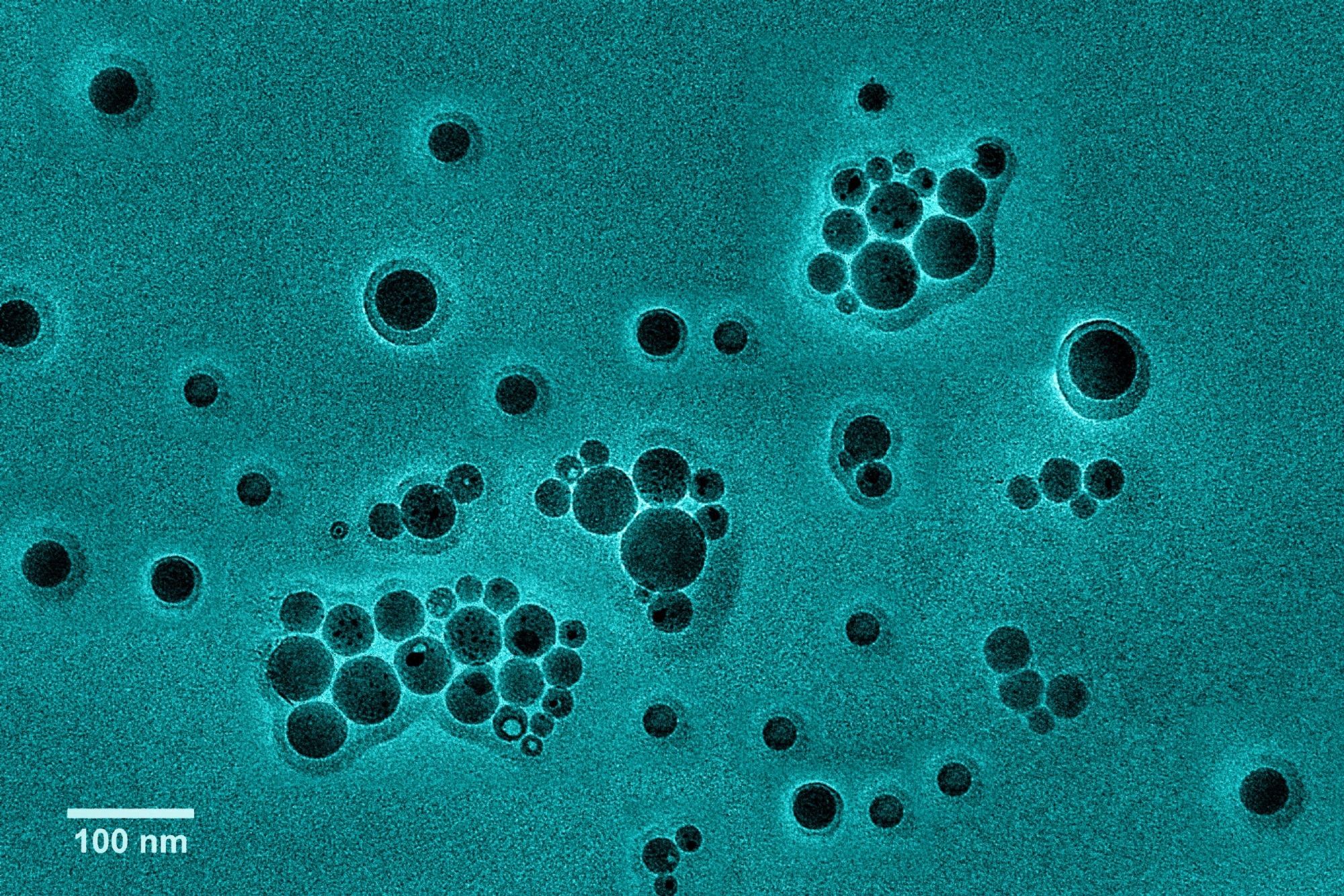

The study focuses on laser ablation in liquids (LAL) as a promising alternative to traditional nanoparticle synthesis. The technique uses ultra-short laser pulses to break down metal targets submerged in liquid, producing highly pure, surfactant-free nanoparticles with controllable size, shape, and composition.

Researchers from Ajou University and Samsung Electronics say LAL could simplify manufacturing for advanced electronics, offering cleaner production and greater scalability.

By fine-tuning the laser’s wavelength, intensity, pulse duration, and liquid medium choice, scientists can create a variety of nanostructures, including pure metals, alloys, metal oxides, and complex core–shell or heterostructures. These ligand-free particles are particularly suited to devices mimicking human senses and synapses, where clean surfaces improve sensitivity and response.

High-entropy alloys and noble-metal nanoparticles made via LAL have shown encouraging performance in these fields. Since these nanoparticles lack surface ligands or impurities, they can interact more efficiently with their surroundings, resulting in sensors that are more sensitive, quicker, and capable of performing many activities simultaneously.

For example, high-entropy alloy nanoparticles have demonstrated potential in hydrogen sensors and brain-like memory systems, whereas nanoparticles derived from noble metals with specific surface characteristics can improve light or gas detection.

Laser ablation in liquids offers a clean and scalable way to produce high-performance nanomaterials. This could fundamentally change how we design and integrate materials for flexible electronics and smart sensory systems.

Sungjun Park, Study Corresponding Author and Professor, Ajou University

Challenges remain in scaling LAL for mass production and maintaining nanoparticle stability without surfactants. The team recommends further research into real-time monitoring, continuous manufacturing, and practical device integration.

LAL could help close the gap between biologically inspired computation and nanomaterial synthesis as smart, immersive technologies become more pervasive in daily life. This would provide a new way of thinking about how to design materials for machines that see, feel, and think more like humans.

Journal Reference:

Choi, J.-G., et al. (2025). Scalable metal-based nanoparticle synthesis via laser ablation in liquids for transformative sensory and synaptic devices. International Journal of Extreme Manufacturing. doi.org/10.1088/2631-7990/ade836.