Oct 22 2010

Jena (21 October 2010) Scientists from the Friedrich-Schiller-University Jena (Germany) were successful in improving a fabrication process for Atomic Force Microscopy (AFM) probe tips.

Atomic Force Microscopy is able to scan surfaces so that even tiniest nano structures become visible. Knowledge about these structures is for instance important for the development of new materials and carrier systems for active substances. The size of the probe is highly important for the image quality as it limits the dimensions that can be visualized – the smaller the probe, the smaller the structures that are revealed.

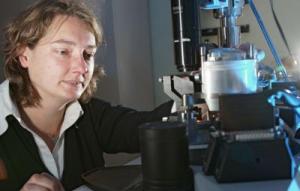

Dr. Stephanie Hoeppener is working with a atomic force microscope for which a Jena researcher team has developed a new procedure allowing to produce sharper probes.

Dr. Stephanie Hoeppener is working with a atomic force microscope for which a Jena researcher team has developed a new procedure allowing to produce sharper probes.

Carbon nanotubes are supposed to be a superior material for the improvement of such scanning probes. However, it is difficult to attach them on scanning probes, which limits their practical use.

Chemists of the Friedrich-Schiller-University Jena found a way to overcome these problems. The research team of Prof. Dr. Ulrich S. Schubert succeeded in developing a new type of process that allows the growth of carbon nanotubes on the actual scanning probe.

For this process the Jena scientists are using microwave radiation for a gentle but very fast growth of the nanotubes. The growth starts at small cobalt particles, that are being taken up with the help of the AFM tip. "The metal particles strongly heat up in the microwave and reach a temperature that is sufficient to convert alcohol vapor into carbon. The heating process works similar like a forgotten spoon in the kitchen microwave which also absorbs the microwave radiation very effectively," explains Tamara Druzhinina from Schubert`s research team. "Carbon nanotubes can be grown very quickly due to the special conditions inside of the microwave which can generate a pressure up to 20 bar" adds her colleague Dr. Stephanie Hoeppener.

The Jena chemist Prof. Schubert points out the practical benefits of the process: "The method we developed can potentially result in a very cost-efficient production technology of for instance high resolution probes for Scanning Force Microscopy. These are already available on the market but they are very expensive at 350 Euro each. With the process we can reach a price level, that would justify the use of such tips also just for routine measurements."

Source: http://www.uni-jena.de/