Mar 7 2016

Ever since its discovery in 2004 graphene has been considered a wonder material, and researchers have great expectations for it. The material is 300 times stronger than steel, and a million times thinner than a human hair. It is also the world’s best conductor of electricity and heat. These features can positively impact many applications, such as making more powerful batteries, more efficient solar panels, and faster computers. Although, it is tough to manipulate graphene beyond it's two-dimensional form.

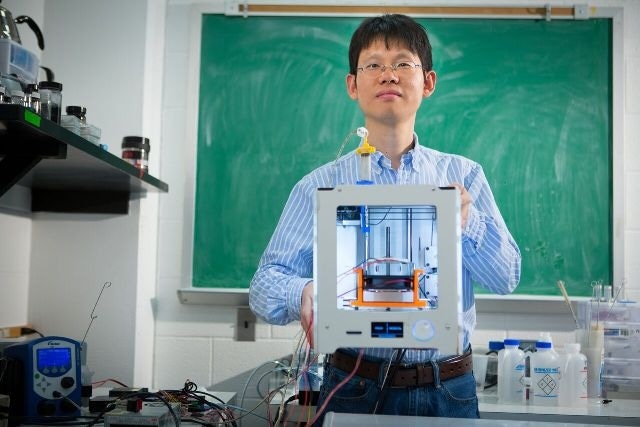

Chi Zhou, Photo credit: University at Buffalo.

Chi Zhou, Photo credit: University at Buffalo.

Recently a suspension of graphene oxide, which is a gel-like form of the material, was poured into freezing molds to produce 3D objects. Although this method is successful, it works only with simple structures that have very little commercial applications.

Using a 3D printer was the next option. The researchers added a polymer or other thickening agent to graphene to strengthen the structure further. However, the delicate structure was damaged when the polymer was removed through a thermal method.

Engineers from the University at Buffalo, Kansas State University and the Harbin Institute of Technology in China have suggested a solution for this issue, published in the 10th February issue of the Small journal. The article illustrates the use of a modified 3D printer and frozen water to produce a 3D truss with overhangs and lattice-shaped cubes using graphene oxide. These structures could potentially help to commercialize graphene, to suit many industries such as medical diagnostic devices, electronics, etc.

Graphene is notoriously difficult to manipulate, but the structures we built show that it’s possible to control its shape in 3D forms.

Chi Zhou, Assistant Professor of Industrial and Systems Engineering, University of Buffalo

In the experiments the graphene oxide was blended with water, and the lattice framework was then printed on a surface at a temperature of -25°C. The graphene was placed between the frozen ice layers to provide a structural support.

On completion of the process, the lattice is dipped in liquid nitrogen. This helps to form much stronger hydrogen bonds. The lattice is then put into a freeze dryer, where the ice is converted into gas and removed. The outcome was an intricate, 3D structure consisting of a graphene aerogel that is capable of retaining its shape at room temperature.

By keeping the graphene in a cold environment, we were able to ensure that it retained the shape we designed. This is an important step toward making graphene a commercially viable material.

Dong Lin, Assistant Professor of Industrial and Manufacturing Systems Engineering, Kansas State University

Going forward the team hopes to add to their current findings by examining a method to produce aerogel structures formed of several materials.

Zhou is a member of the Sustainable Manufacturing and Advanced Robotic Technologies (SMART), a UB Community of Excellence launched in 2015; he is also a member of UB’s New York State Center of Excellence in Materials Informatics.

The study’s first authors are Qiangqiang Zhang, a student at Harbin, and Feng Zhang, a student at UB. Contributing authors are Hui Li, a student at Harbin, and Sai Pradeep Medarametla, a student at Kansas State University. Mark T. Swihart, UB Distinguished Professor of Chemical and Biological Engineering, and Jonathan F. Lovell, assistant professor of biomedical engineering at UB assisted the research team. Swihart and Lovell are faculty members within UB’s School of Engineering and Applied Sciences.