Dec 12 2018

Up to the present time, it has proved very challenging to convert the promises of the wonder material graphene into useful applications. Amedeo Bellunato, PhD candidate at the Leiden Institute of Chemistry has formulated a process of cutting graphene into smaller fragments with a diamond knife. He can then build nanostructures from the fragments.

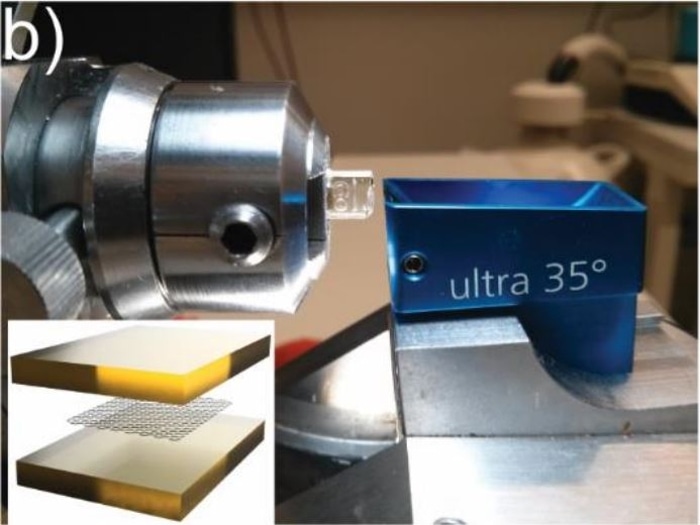

The microtome that cuts exceptionally precise strips of graphene. The sandwich with the graphene (inset) is the transparent block to the left, and the diamond knife can be seen at the edge of the blue container. (Image credit: Universiteit Leiden)

The microtome that cuts exceptionally precise strips of graphene. The sandwich with the graphene (inset) is the transparent block to the left, and the diamond knife can be seen at the edge of the blue container. (Image credit: Universiteit Leiden)

Graphene is a honeycomb structure containing carbon atoms measuring just a single atom in thickness. Following its discovery in 2004, it appeared to be the perfect basic material for nanotechnology applications: it is extremely strong and it is a remarkably good conductor of both electricity and heat. In 2013, the EU introduced the Graphene Flagship, a research program with a budget of a billion euros to create such applications as more efficient solar cells, batteries, LEDs, and all kinds of sensors.

However, in his dissertation, Bellunato remarks that creating such nanostructures is still a very complex production process that does not work well in serial production. Furthermore, it has proven nearly impossible to selectively “functionalize” graphene chemically, i.e. to link other chemical elements, such as nitrogen or oxygen atoms, to the edges of a graphene nanostructure. It is vital to be able to achieve this so as to make graphene into a versatile nanomaterial with numerous applications.

Graphene sandwich

Enthused by former experiments, Bellunato decided to adopt a different technique that is to take a sandwich of metal and plastic with a layer of graphene in the middle and to literally cut it into fragments. He accomplished this using a microtome, a diamond knife that can cut fragments with nanometer precision.

In the cutting edge of the sandwich, a flawlessly clean, one-atom-thick edge of graphene is exposed, to which other molecules or atoms can be attached by chemical means. The graphene slice can also be linked to an electrical current, transforming it into an electrochemical cell. This can be compared with the electrochemical coating of a metal, but then at nanoscale, as only the edge of the graphene is coated. Bellunato was also able to construct a sandwich of nanopores and nanogaps of graphene with microscopically thin strips.

Kruiselings

It also showed the possibility to make a so-called tunnel junction. This takes place between two electrical conductors, when they are within a few nanometers of one another at a specific point. A minute current can then pass between the two conductors. As the flow of energy is highly sensitive to the distance between the conductors, this tunnel effect forms the foundation for all kinds of very sensitive sensors.

This tunnel junction is not new. It is a matter of refining the technique, and then it should have practical applications within five years or so.

Amedeo Bellunato, PhD Candidate, Leiden Institute of Chemistry.

The unconventional method that he developed will not mainly be used in consumer products, he supposes, but rather in advanced research instruments.