When opposed to an uncoated surface, the overall secondary electron yield of the C/TiN components nanofilm produced via plasma-enhanced atomic layer deposition reduces by 25%.

Secondary electron emissions suppression is critical in resolving the multipactor for high-power microwave devices in space. The multipactor phenomenon occurs in vacuum tubes and waveguides used in radio-frequency (RF) amplifiers when particular circumstances, such as secondary electron emission, are present.

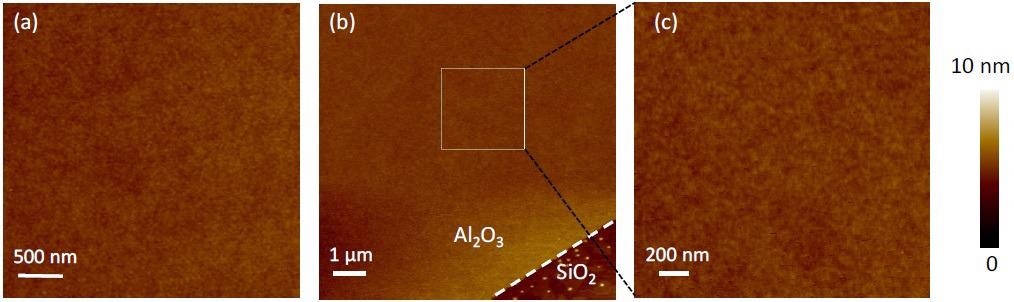

The atomic force microscopy images of SiO2 before (a) and after (b,c) Al2O3 deposition. Image Credit: Xie, G., et al.

Aircraft Technology is Evolving

Due to the rapid advancement of information and communication innovation, the use of aircraft technology has become increasingly significant. As a result, aviation microwave element miniaturization and high-frequency development have become increasingly important in enabling innovation.

Advanced aircraft manufacturing technology has attracted notoriety, and researchers have created numerous technologies to improve productivity, reduce consumption of energy and resources, and design higher quality products.

One challenge that needs to be addressed for high-power aviation microwave technology is the multipactor, caused by secondary electron emission (SEE) in a space under an RF electromagnetic field caused by excessive energy density.

Advanced production processes have sparked considerable worry as operations of different firms have progressed, notably in the aerospace sector.

The use of ultra-thin atomic layer deposition nanofilms in modern aerospace manufacturing is particularly relevant in the formation of high-power and miniaturized systems.

Methods to Suppress Multipactor

Several methods for suppressing the secondary electron yield (SEY), which is crucial for multipactor suppression, have been devised. These techniques can be classified into manufactured surface roughness and intrinsic low-SEY coating.

The former uses the nanoparticles of the electron traps, which may confine low-energy electrons and result in a reduced surface SEY. SEY suppression based on low-SEY coatings is more effective and avoids damaging the electronic properties of microwave components.

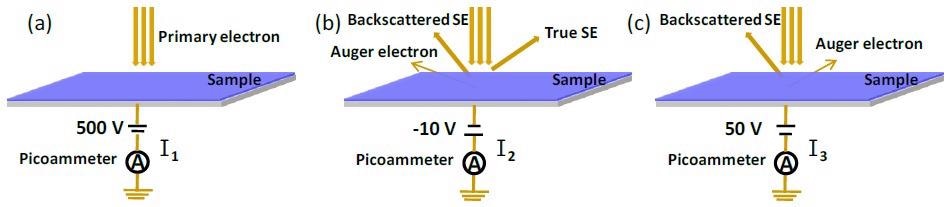

The schematic representation of the experimental system for SEY measurement. (a) The sample current I1 represents primary currents IPE; (b) the sample current I2 represents IPE–Itot SE; (c) the sample current I3 represents IPE–IBSE–IAE. Image Credit: Xie, G., et al.

Nanofilm in Modern Aerospace Manufacturing

Ultra-thin ALD nanofilms are used in the modern aerospace manufacturing sector; for example, thermal ALD creates compact aluminum oxide nanofilm.

Backscattered electrons yield was used to evaluate the surface oxidation of aluminum following the initial deposition of ultra-thin aluminum oxide nanofilms.

Research findings showed that the ALD nanofilm could resist oxidation, and the study presented a broad way for high-quality surface processing and storage in the advanced aircraft manufacturing business.

Plasma-enhanced ALD was used to create titanium nitride and amorphous carbon.

Compared to an uncoated sample, the secondary electron yield of composites nanofilm was reduced by 25%. Secondary electron emissions suppression is critical in solving multipactor for high-power microwave circuits in space and the electron cloud for massive, high-energy particle accelerators.

Results of ALD and TiN Nanofilm Usage

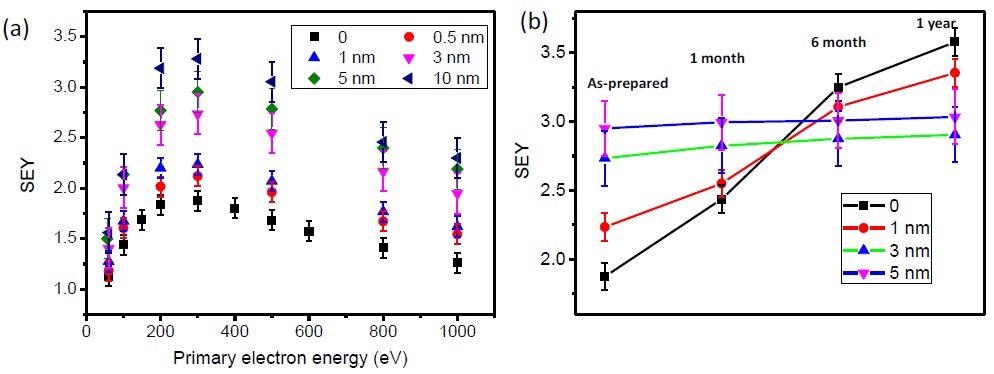

Without the ALD nanofilm, the SEY of aluminum grew significantly. The naturally oxidized layer was noncompact, and the present oxide layer could not prevent oxidation of the inner substance.

The thickness of the oxide film after one year of storage was predicted to be less than 5 nm, indicating that the compact and homogenous nanofilm could avoid aluminum oxidation.

The ALD film has substantially better uniformity than the plated silver film. Though TiN conductivity is higher than most other low-SEY coatings, it is still lower than silver due to the tiny skin depth of high-frequency RF devices, particularly millimeter devices.

An excess of TiN film can raise insertion loss. It is critical to investigate the quantitative link between the SEY and the film thickness of the uppermost TiN.

The SEY measurement of aluminum with different ALD processes. (a) The SEY as a function of primary electron energy with different thicknesses; (b) the change of SEYmax with time. Image Creadit: Xie, G., et al.

Advantage of this Research

Given that TiN nanofilms can also be employed as anti-radiation coatings, the ALD composite nanofilm of TiN and carbon has great potential in high-power spacecraft.

The SEY's stability with the ALD nanofilm is critical for engineering applications. At various intervals, the SEY of samples with an ALD nanofilm was investigated. The results demonstrated that a compact aluminum oxide coating might prevent oxidation and preserve aluminum's high quality throughout storage.

Challenge for Further Research

Carbon compounds, such as graphite, have a considerably lower SEY than TiN. However, creating a high-quality, stable, controlled carbon nanofilm on a well-designed aluminum alloy surface is challenging. In this research plasma-enhanced ALD was able to lower the temperature of a reaction when compared to a typical thermal reaction.

Continue reading: Applying Nanocoatings to Aviation: A Review.

Reference

Xie, G., et al. (2021). The Applications of Ultra-Thin Nanofilm for Aerospace Advanced Manufacturing Technology. Nanomaterials 2021, 11(12), 3282; Published: 3 December 2021. Available at: https://www.mdpi.com/2079-4991/11/12/3282

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.