Professor Hu Jinlian from the City University of Hong Kong (CityUHK) highlights the importance of integrating electrospinning and electrospraying, as published in Matter, to advance nanomaterial synthesis, with potential applications in various industries including bioengineering, textiles, defense, and energy.

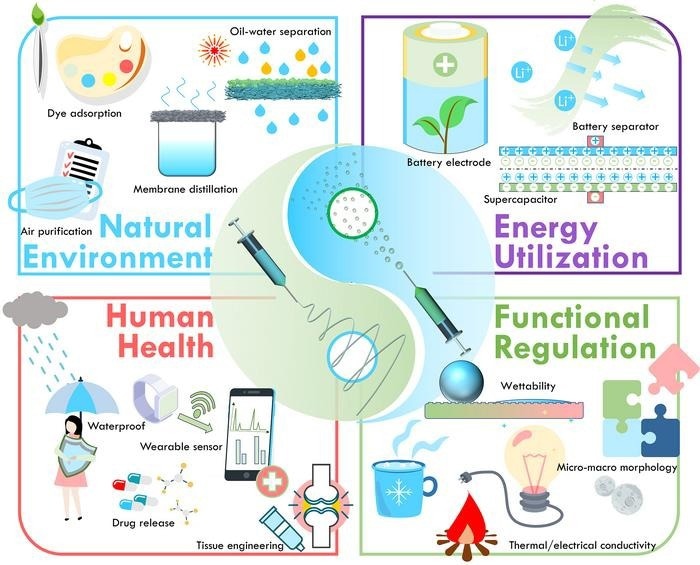

Typical applications of EES for the natural environment, energy utilization, human health, and functional regulation. Image Credit: City University of Hong Kong

Typical applications of EES for the natural environment, energy utilization, human health, and functional regulation. Image Credit: City University of Hong Kong

Professor Hu, who studies electrospinning, electrospraying, nanofibers, nanomaterials, human health, and functional membranes, contends that the electrospinning and electrospraying synergism (ESS) can have a positive impact on a variety of industries, including bioengineering, textile technology, medical treatment, defense technology, intelligent manufacturing, and energy conversion.

This highly integrated ESS technology has received great attention from scientists in the last decade, but we are now facing a critical bottleneck period and seeing hidden problems because of rapid development over the past decade.

Hu Jinlian, Professor, Department of Materials Science and Engineering and Biomedical Engineering, City University of Hong Kong

EES technology offers unparalleled benefits compared to other micro-nano material preparation processes. It provides exceptional control over the diameter, orientation, morphology, density, pore size, and chemical properties of nanofibers; it offers to shorten the steps required in micro-nano material preparation technologies, such as 3D printing, lithography, or other chemical methods; and it realizes the ideal combination of 1D fiber and 0D/3D micro-nano particles.

However, the obstacles are numerous. They include the need for more systematic generalization, summary, and categorization, as well as the separation between the scientific community and industry.

Hu contends that the focus of ongoing research into combining electrospinning and electrospraying mechanisms tends to avoid the issue of process synergy and instead emphasizes the two separate technologies, glossing over the benefits that can be captured through possible coordination and cooperation between the two.

“If the concept of EES technology can be generalized, it will undoubtedly give scientists new ideas and inspire many studies. In turn, it can also vigorously promote the iteration and upgrade of EES technology,” Professor Hu added.

The Matter study “Electrospinning and electrospraying synergism: Twins-tech collaboration across dimensions” demonstrates how electrospinning and electrospraying are similar phenomena. However, there are distinctions.

Hu further stated, “E-spinning technology is often used as the construction method of the main structure. It should be noted that e-spinning technology can sometimes be used for surface modification or regulation purposes. E-spraying technology is generally used as the control or modification means of material properties.”

What Will EES Produce in the Future?

First, EES technology will significantly enhance the preparation of micro-nano composite materials. It will be feasible to create complex structures that are difficult to acquire using typical chemical procedures, which is critical for catalysis, drug loading, and biological detection.

Second, EES technology will change the landscape of practical apparel. Giving garments unique features like waterproofing, cooling/warming, anti-UV, health detection, and so on will become a commodities development trend.

Furthermore, industrial assembly lines for EES equipment will join the plant, completing supply chains, while sales channels will progressively emerge.

Researchers could contribute to various sectors by combining the two processes rather than doing so individually. For example, in the natural environment, they can purify, recover, and reuse water resources utilizing porous membrane materials.

In addition to detoxifying dirty water, nanofiber membranes based on the EES method can also be used to capture water by directly converting environmental water vapor into clean water. EES might potentially be used to improve energy efficiency, human health, and functional membranes.

Professor Hu concluded, “EES technology has become an important means of preparing micro-nanoscale composite functional materials over the past 20 years. This is a critical period for its ability to overcome major challenges and move toward future success. We should have an open, enterprising, and innovative mentality to promote the next round of the EES technological revolution.”

Journal Reference:

Si, Y., et. al. (2024) Electrospinning and electrospraying synergism: Twins-tech collaboration across dimensions. Matter. doi:10.1016/j.matt.2024.01.009.