Since its discovery in 2004, graphene has been transforming materials science and related fields. Graphene is made up of two-dimensional carbon atom sheets combined to form a thin, hexagon-shaped, one-atom thick structure. It has exceptional chemical and physical qualities.

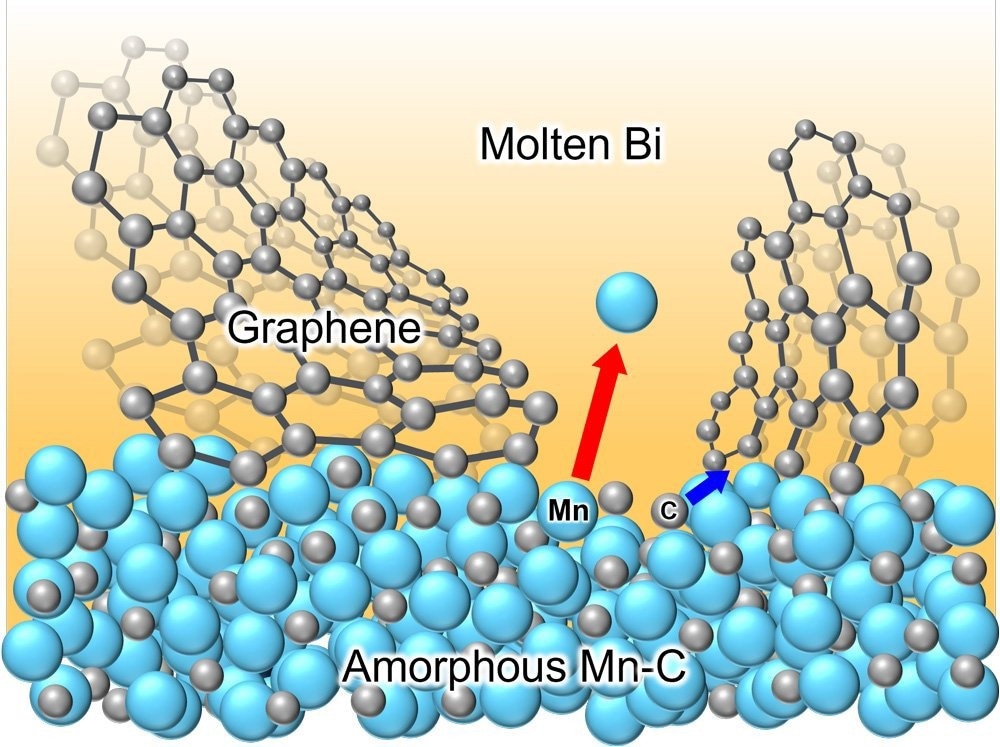

Schematic illustration for the formation NCG during liquid metal dealloying of amorphous manganese-carbon (Mn-C) alloy in a molten bismuth (Bi) to induce selective dissolution of manganese (Mn) atoms and self-organization of carbon (C) atoms into graphene layers. Image Credit: ©S.H. Joo & H. Kato.

Schematic illustration for the formation NCG during liquid metal dealloying of amorphous manganese-carbon (Mn-C) alloy in a molten bismuth (Bi) to induce selective dissolution of manganese (Mn) atoms and self-organization of carbon (C) atoms into graphene layers. Image Credit: ©S.H. Joo & H. Kato.

Despite its thinness, graphene is extremely transparent, strong, light, and flexible. It also shows exceptional thermal and electrical conductivity, a large surface area, and gas impermeability. Its unparalleled versatility in applications extends to high-speed transistors and biosensors.

A specialized type of graphene called nanocellular graphene (NCG) is created by stacking multiple graphene layers and manipulating its internal structure using a nanoscale cellular morphology. This allows NCG to achieve a large specific surface area.

NCG is highly sought after due to its ability to enhance the functionality of energy devices, sensors, and electronic devices. However, flaws that arise in the manufacturing process have halted its advancement. When NCGs form, cracks frequently appear. Scientists are searching for new processing technologies to create homogeneous, seamless, and crack-free NCGs at suitable scales.

We discovered that carbon atoms rapidly self-assemble into crack-free NCG during liquid metal dealloying of an amorphous Mn-C precursor in a molten bismuth.

Won-Young Park, Graduate Student, Tohoku University

Dealloying takes advantage of alloy constituents' different degrees of miscibility in a molten metal bath. Through this process, some alloy components are selectively corroded while remaining intact.

After graphitization, Park and colleagues showed that NCGs using this technique had high conductivity and tensile strength. They also tested the substance in a sodium-ion battery (SIB).

We used the developed NCG as an active material and current collector in a SIB, where it demonstrated a high rate, long life, and excellent deformation resistance. Ultimately, our method of making crack-free NCG will make it possible to raise the performance and flexibility of SIBs - an alternative technology to lithium-ion batteries for certain applications, particularly in large-scale energy storage and stationary power systems where cost, safety, and sustainability considerations are paramount.

Won-Young Park, Graduate Student, Tohoku University

Soo-Hyun Joo from the Institute of Materials Research (currently based at Dankook University) collaborated with Hidemi Kato from the same institute, working alongside Park. The details of their research were published in the journal Advanced Materials on February 23rd, 2024.

Researchers from Pohang University of Science and Technology, Johns Hopkins University, Tohoku University’s Frontier Research Institute for Interdisciplinary Sciences, and the Fracture and Reliability Research Institute collaborated to make their efforts possible.

Journal Reference:

Park, W., et al. (2024) Mechanically Robust Self-Organized Crack-Free Nanocellular Graphene with Outstanding Electrochemical Properties in Sodium Ion Battery. Advanced Materials. doi.org/10.1002/adma.202311792