A research team at KIST has developed an environmentally friendly palladium recovery technology using titanium-based maxene nanosheets (TiOx/Ti3C2Tx).

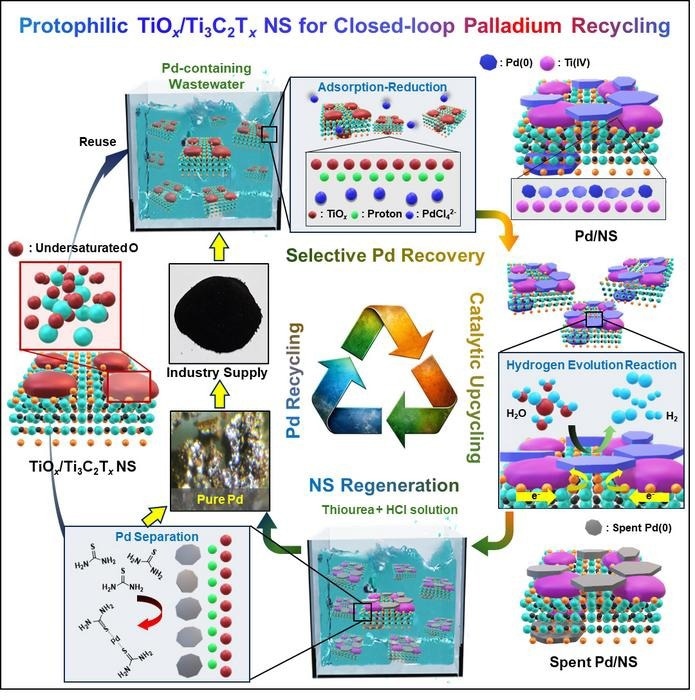

Using TiOx/Ti3C2Tx nanosheets, we selectively recovered palladium from spent catalysts and repurposed it as a hydrogen evolution catalyst. Subsequently, we achieved high-purity separation of the nanosheets and palladium for industrial reuse, while reusing the nanosheets themselves. This completes a fully closed-loop resource recycling system. Image Credit: Korea Institute of Science and Technology.

Using TiOx/Ti3C2Tx nanosheets, we selectively recovered palladium from spent catalysts and repurposed it as a hydrogen evolution catalyst. Subsequently, we achieved high-purity separation of the nanosheets and palladium for industrial reuse, while reusing the nanosheets themselves. This completes a fully closed-loop resource recycling system. Image Credit: Korea Institute of Science and Technology.

Palladium (Pd) is widely used in various industries and everyday products, including smartphones, semiconductor manufacturing, and hydrogen fuel cells. Palladium functions as an excellent catalyst, even in trace amounts. It can help reduce pollutants and enhance energy efficiency.

Nevertheless, palladium production is concentrated in a limited number of countries, resulting in an unstable supply, and a shortage of environmentally friendly and efficient recovery technologies means much is either discarded or relies on foreign technology.

Published in Advanced Functional Materials, the study, led by Dr. Jae-Woo Choi and Dr. Jin Young Kim, demonstrates a nanocluster platform that can accelerate Palladium production.

This technology uses a high-density configuration of “TiOx nanoclusters” with unsaturated oxygen on the nanomaterial surface. It allows for the recovery of 99.9 % high-purity palladium in 30 minutes, even in weakly acidic conditions where conventional methods struggle.

It does not need toxic chemicals or a power source, and the recovered palladium spontaneously reduces to its metallic form, facilitating separation via simple filtration. This results in a substantial reduction in energy use and carbon emissions compared to current strong acid processes.

Moreover, this material demonstrates exceptional adsorption performance at 1,983 mg/g and retains roughly 90 % efficiency after over 10 reuse cycles, validating its stability and reusability. The recovered palladium-nanosheet composite can be repurposed as a hydrogen evolution catalyst, making it appropriate for a complete precious metal recycling system.

This technology functions at room temperature, eliminating the need for high-temperature processing or harsh acidic chemicals. Consequently, it is projected to cut carbon emissions by 80 % or more compared to current methods. It also offers cost benefits due to its lack of electricity consumption and high industrial value, as it is reusable.

A significant advantage is its wide range of applications. It is applicable as a catalyst in industries like refining, petrochemicals, automotive, and hydrogen fuel cells, and for recovering palladium from electronic waste, including smartphones and circuit boards.

KIST researchers plan to further refine this technology for real-time treatment of palladium-containing wastewater from industrial sources. Their goal is a circular resource ecosystem, reusing recovered palladium as a catalyst and electronic material.

Future development includes recovery technologies for other precious metals, such as platinum, gold, and silver.

This research represents a technological turning point that can contribute to the self-sufficiency of Korea's resource circulation system and reduce dependence on precious metal imports by enabling the easy recovery of precious metals previously discarded in spent catalysts or electronic waste. We plan to enhance commercialization potential by developing a modular recovery system in the future.

Dr. Jae-Woo Choi, Korea Institute of Science and Technology

“We confirmed that the recovered palladium can be applied not merely as recycled material, but as an electrochemical electrode catalyst material for producing high-efficiency hydrogen. We verified the potential for it to be utilized not as a 'discarded metal,' but as a circular resource supporting clean energy production,” details Dr. Jin Young Kim of KIST, who collaborated on the research.

Journal Reference:

Jung, Y., et al. (2025). Protophilic TiOx/Ti3C2Tz Nanosheets for Hyper-Efficient Closed-Loop Pd Recycling. Advanced Functional Materials. DOI: 10.1002/adfm.202511809.