Oct 22 2009

Scientists at the California Institute of Technology (Caltech) have uncovered the physical mechanism by which arrays of nanoscale (billionths-of-a-meter) pillars can be grown on polymer films with very high precision, in potentially limitless patterns.

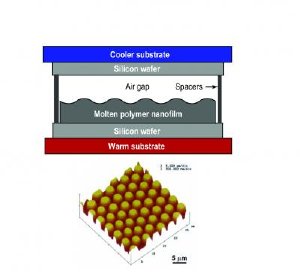

The upper image is a schematic showing typical experimental setup. Lower panel is an AFM image of 260 nm high nanopillars spaced 3.4 microns apart which formed in a polymer film. Credit: Upper: Dietzel and Troian, PRL 103, 074501 (2009). Lower: Chou and Zhuang, J. Vac. Sci. Technol. B 17, 3197 (1999)

The upper image is a schematic showing typical experimental setup. Lower panel is an AFM image of 260 nm high nanopillars spaced 3.4 microns apart which formed in a polymer film. Credit: Upper: Dietzel and Troian, PRL 103, 074501 (2009). Lower: Chou and Zhuang, J. Vac. Sci. Technol. B 17, 3197 (1999)

This nanofluidic process-developed by Sandra Troian, professor of applied physics, aeronautics, and mechanical engineering at Caltech, and described in a recent article in the journal Physical Review Letters-could someday replace conventional lithographic patterning techniques now used to build three-dimensional nano- and microscale structures for use in optical, photonic, and biofluidic devices.

The fabrication of high-resolution, large-area nanoarrays relies heavily on conventional photolithographic patterning techniques, which involve treatments using ultraviolet light and harsh chemicals that alternately dissolve and etch silicon wafers and other materials. Photolithography is used to fabricate integrated circuits and microelectromechanical devices, for example.

However, the repeated cycles of dissolution and etching cause a significant amount of surface roughness in the nanostructures, ultimately limiting their performance.

"This process is also inherently two-dimensional, and thus three-dimensional structures must be patterned layer by layer," says Troian.

In an effort to reduce cost, processing time, and roughness, researchers have been exploring alternative techniques whereby molten films can be patterned and solidified in situ, and in a single step.

About a decade ago, groups in Germany, China, and the United States encountered a bizarre phenomenon while using techniques involving thermal gradients. When molten polymer nanofilms were inserted within a slender gap separating two silicon wafers that were held at different temperatures, arrays of nanoscale pillars spontaneously developed.

These protrusions grew until they reached the top wafer; the resulting pillars were typically several hundred nanometers high and several microns apart.

These pillars sometimes merged, forming patterns that looked like bicycle chains when viewed from above; in other films, the pillars grew in evenly spaced, honeycomb-like arrays. Once the system was brought back down to room temperature, the structures solidified in place to produce self-organized features.

In 2002, researchers in Germany who had observed this phenomenon hypothesized that the pillars arise from infinitesimal-but very real-pressure fluctuations along the surface of an otherwise quiescent flat film. They proposed that the differences in surface pressure were caused by equally tiny variations in the way individual packets (or quanta) of vibrational energy, known as phonons, reflect from the film interfaces.

"In their model, the difference in acoustic impedance between the air and polymer is believed to generate an imbalance in phonon flux that causes a radiation pressure that destabilizes the film, allowing pillar formation," says Troian. "Their mechanism is the acoustic analogue of the Casimir force, which is quite familiar to physicists working at the nanoscale."

But Troian, who was familiar with thermal effects at small scales-and knew that the propagation of these phonons is actually unlikely in amorphous polymer melts, which lack internal periodic structure-immediately recognized that another mechanism might be lurking in this system.

To determine the actual cause of nanopillar formation, she and Caltech postdoctoral scholar Mathias Dietzel developed a fluid-dynamical model of the same type of thin, molten nanofilm in a thermal gradient.

Their model, Troian says, "exhibited a self-organizing instability that was able to reproduce the strange formations," and showed that nanopillars, in fact, form not via pressure fluctuations but through a simple physical process known as thermocapillary flow.

In capillary flow-or capillary action-the attractive force, or cohesion, between molecules of the same liquid (say, water) produces surface tension, the compressive force that is responsible for holding together a droplet of water. Since surface tension tends to minimize the surface area of a liquid, it often acts as a stabilizing mechanism against deformation caused by other forces. Differences in temperature along a liquid interface, however, generate differences in surface tension. In most liquids, cooler regions will have a higher surface tension than warmer ones-and this imbalance can cause the liquid to flow from warmer- to cooler-temperature regions, a process known as thermocapillary flow.

Previously, Troian has used such forces for microfluidic applications, to move droplets from one point to another.

"You can see this effect very nicely if you move an ice cube in a figure eight beneath a metal sheet coated with a liquid like glycerol," she says. "The liquid wells up above the cube as it traces out the figure. You can draw your name in this way, and, presto! You have got yourself a new form of thermocapillary lithography!"

In their Physical Review Letters paper, Troian and Dietzel showed how this effect can theoretically dominate all other forces at nanoscale dimensions, and also showed that the phenomenon is not peculiar to polymer films.

In the thermal-gradient experiments, they say, the tips of the tiny protrusions in the polymer film experience a slightly colder temperature than the surrounding liquid, because of their proximity to the cooler wafer.

"The surface tension at an evolving tip is just a little bit greater, and this sets up a very strong force oriented parallel to the air/polymer interface, which bootstraps the fluid toward the cooler wafer. The closer the tip gets to the wafer, the colder it becomes, leading to a self-reinforcing instability," Troian explains.

Ultimately, she says, "you can end up with very long columnar structures. The only limit to the height of the column, or nanopillar, is the separation distance of the wafers."

In computer models, the researchers were able to use targeted variations in the temperature of the cooler substrate to control precisely the pattern replicated in the nanofilm. In one such model, they created a three-dimensional "nanorelief" of the Caltech logo.

Troian and her colleagues are now beginning experiments in the laboratory in which they hope to fabricate a diverse array of nanoscale optical and photonic elements. "We are shooting for nanostructures with specularly smooth surfaces-as smooth as you could ever make them-and 3-D shapes that are not easily attainable using conventional lithography," Troian says.

"This is an example of how basic understanding of the principles of physics and mechanics can lead to unexpected discoveries which may have far-reaching, practical implications," says Ares Rosakis, chair of the Division of Engineering and Applied Science (EAS) and Theodore von Kármán Professor of Aeronautics and Mechanical Engineering at Caltech. "This is the real strength of the EAS division."