Molybdenum Ditelluride (MoTe2): Why is it Important?

Transition metallic dichalcogenides (TMDs) have gained a lot of interest among 2D substances because of their extraordinary characteristics. In comparison to other TMDs, molybdenum ditelluride (MoTe2) has attracted significant attention owing to its process-tunable amorphous phases, notably the conductive 1T' and semiconducting 2H phases.

The 1T' phase, which possesses an orthorhombic composition, is the precursor step for accessing remarkable topological features and is of particular relevance as a host for the atomic spin hall phenomenon in individual and multilayered nanosheets. On the other hand, 2H-MoTe2 has significant promise as a 2D layered material in nanoelectronics due to its tiny bandgap, good absorption, and low thermal conductance.

As a result, MoTe2 is considered a remarkable design material for investigating phase transition features with various associated applications, such as 2D non-volatile storage devices. This is because of the minor energy variations between the two aforementioned amorphous phases of MoTe2 nanosheets.

Additionally, MoTe2 is a promising option for applications such as field-effect devices, microelectronics, and energy storage due to its ultrahigh movement, optical transmittance, thin architecture, and chemical resistance. However, clear knowledge and a repeatable growth strategy are necessary for moving MoTe2 from the lab to the manufacturing level.

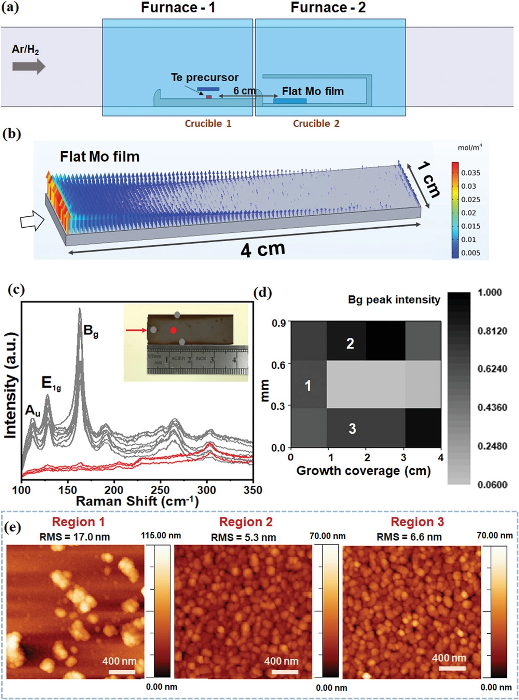

a) CVD schematic illustration of the experimental set-up for MoTe2 growth in flat configuration. b) View of the out-of plane component of Te concentration gradient distribution along 4 cm × 1 cm substrate size from COMSOL simulations. c) Raman spectra of as-grown MoTe2 taken at different regions across the sample surface as indicated by the grey (MoTe2 growth regions) and red (no growth) dots in the inset (flow direction indicated by red arrow). d) Raman map of Bg (g in pedix format) mode intensity distribution over 4 cm × 1 cm substrate size. e) AFM topography images of as-grown MoTe2 taken at corresponding three regions 1, 2, and 3 in panel (d). Image Credit: Tummala, P. P. et al., Advanced Materials Interfaces

Chemical Vapor Deposition (CVD) for Producing MoTe2 Nanosheets

Mechanical abrasion, chemical emulsification, and physical vapor formation have typically been used to create few-layer TMDs such as MoTe2. However, these approaches have significant disadvantages because of their inaccurate phase control, roughness, unpredictable distribution, and non-uniformity.

Realizing the maximum potential of MoTe2 nanosheets requires a dependable synthesis method for carefully controlling their phase structure and homogeneous large-area development. The establishment of a single-stage synthesis process of MoTe2 nanosheets remains one of the greatest obstacles in their industrial applications. The incorporation of large-area MoTe2 nanosheets into a variety of possible applications requires a thorough understanding of the variable phase transformation and growth factors.

In this context, chemical vapor deposition (CVD) through the tellurization of a pre-deposited molybdenum thin film is a straightforward and versatile method for manufacturing large-scale MoTe2 nanosheets. Both 1T' and 2H-MoTe2 nanosheets may be produced by accurately controlling the kinetics and thermodynamics of the MoTe2 crystal development during the CVD process.

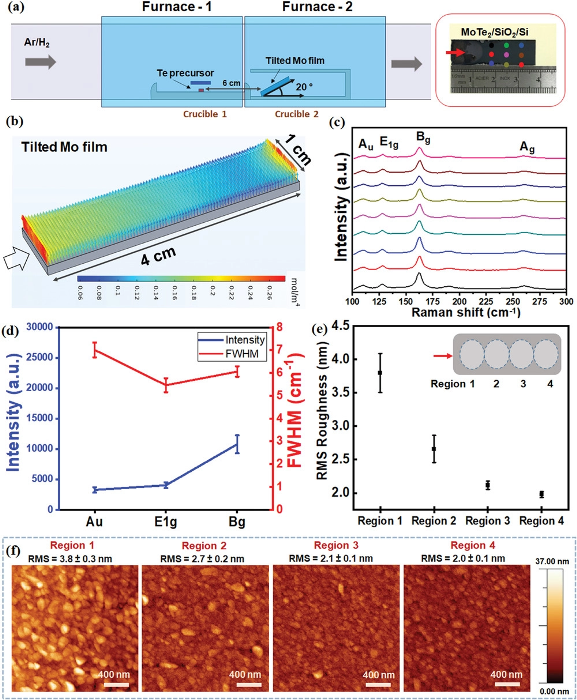

a) CVD schematic illustration of the experimental set-up for MoTe2 growth in tilted (20°) configuration and photograph of the obtained MoTe2. b) COMSOL 3D model showing the Te concentration gradient along the 4 cm × 1 cm sample surface; the arrow indicates the flow direction. c) Raman spectra of 1T'-MoTe2, normalized with respect to Bg peak intensity, taken at different regions as indicated by the colored dots in the photograph in (a). d) Average (among the measured points) Raman intensity (blue y-axis) and FWHM (red y-axis) of 1T'-MoTe2 Au, E1g, and Bg phonon modes. e) RMS roughness from AFM collected at the different regions imaged in (f); the schematic in the inset identifies the different regions over the sample surface. f) AFM topography images of as-grown MoTe2 taken at corresponding regions shown in (e) inset. Image Credit: Tummala, P. P. et al., Advanced Materials Interfaces

Highlights of the Current Study

In this study, the researchers conducted a series of chemical vapor deposition experiments to generate MoTe2 nanosheets as a combination of the tellurium intensity gradient and substrate alignment.

Using the CVD process, the researchers showed a straightforward and repeatable method for the uniform development of MoTe2 nanosheets across a vast area by analyzing the tellurization dynamics on the reaction interface. The researchers evaluated two geometrical combinations of the pre-deposited molybdenum sheet, namely flat and tilted inclinations.

Simulations based on the finite element method (FEM) were performed to anticipate the growth topologies of relevance and connect them with the actual findings on MoTe2 film produced under the same circumstances.

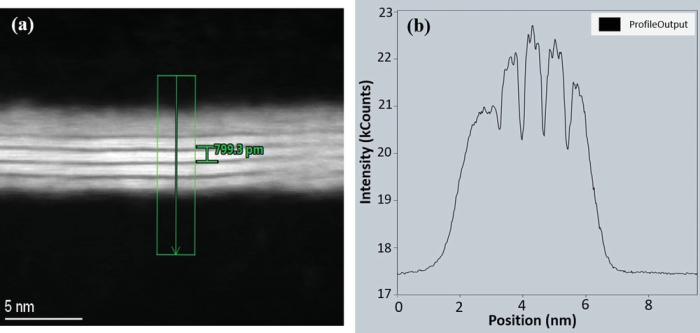

Several characterization techniques, including atomic force microscopy (AFM) and micro-Raman spectroscopy, were used to validate the orientation, cleanliness, and homogeneity of the as-produced MoTe2 nanosheets.

a) HR-TEM HAADF cross section of a representative MoTe2 nanosheet; single layers are evident and separated by van der Waals spacing; b) line profile across the MoTe2 thickness, where the position of Mo and Te atoms can be elucidated. Image Credit: Tummala, P. P. et al., Advanced Materials Interfaces

Important Findings

The computational results, together with the experimental data, are essential for comprehending the kinetics involved in CVD-based MoTe2 formation.

These synergistic modeling and laboratory findings show that, in addition to the tellurium quantity, the substrate inclination in the development process strongly determines the intensity gradient of the tellurium vapor at the reaction location, allowing for intimate control of the MoTe2 structure and morphology.

Based on these results, it is reasonable to conclude that this research offers a pivot mechanism for scalable 1T' and 2H-MoTe2 incorporation in applications for innovative nanoelectronics, optoelectronics, spectroscopy, and thermodynamic devices.

Moreover, this study describes a technique that might be regarded as an efficient, flexible, and relatively easy option for permitting regulated development and improving the features of TMDs.

Reference

Tummala, P. P. et al. (2022). Large Area Growth and Phase Selectivity of MoTe2 Nanosheets through Simulation-Guided CVD Tellurization. Advanced Materials Interfaces. Available at: https://doi.org/10.1002/admi.202200971

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.