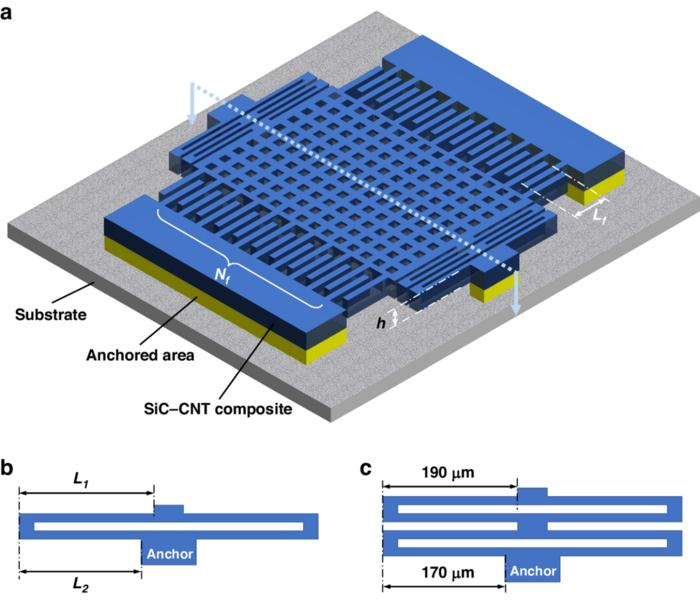

A schematic of the accelerometer. a Typical structure of a MEMS comb-type accelerometer, b single-meandered spring, c double-meandered spring. Image Credit: Microsystems & Nanoengineering

The demand for microelectromechanical systems (MEMS) resilient to harsh environments is increasing. Silicon-based MEMS face challenges under extreme conditions, as their performance is constrained by limitations at elevated temperatures.

To overcome this limitation, one particularly interesting option is silicon carbide (SiC), which provides unparalleled mechanical, electrical, and thermal benefits for long-lasting MEMS.

Despite its potential, SiC MEMS development is challenged by the intricacies of bulk micromachining, calling for innovative strategies to harness SiC's strengths in crafting robust devices.

To this end, researchers have created an accelerometer that can withstand extreme environmental stress by utilizing a novel silicon carbide-carbon nanotube (SiC-CNT) composite. The study published in Microsystems & Nanoengineering reveals a novel material fusion that combines the conductive properties and robustness of CNTs with the versatility and adaptability of SiC.

This work merges the resilience of SiC with the versatility of CNTs.

The team's method entails growing a CNT array and using chemical vapor deposition to densify it with amorphous SiC. This produces a material that has exceptional mechanical strength, superior electrical conductivity, and high thermal stability. This SiC-CNT composite ensures reliable performance in harsh temperatures and corrosive environments while facilitating the creation of high aspect ratio structures, which are essential for the sensitivity and efficiency of MEMS devices.

This advancement not only overcomes longstanding fabrication challenges but also significantly enhances the mechanical and electrical properties of MEMS devices. Our SiC-CNT composite accelerometers are poised to revolutionize the deployment of MEMS in environments where conventional devices simply cannot survive.

Sten Vollebregt, Professor and Lead Researcher, Delft University of Technology

The composite’s potential in MEMS applications was demonstrated by the fabricated capacitive accelerometer, especially for devices that need to operate in corrosive, high-temperature, and high-radiation environments. These accelerometers are essential for industrial, automotive, and aerospace monitoring systems where dependability in harsh environments is crucial.

Journal Reference:

Mo, J., et al. (2024) A high aspect ratio surface micromachined accelerometer based on a SiC-CNT composite material. Microsystems & Nanoengineering. doi.org/10.1038/s41378-024-00672-x