Researchers are increasingly using micro- and nanoscale structures for more precise control of heat flow in extreme-power electronic systems.

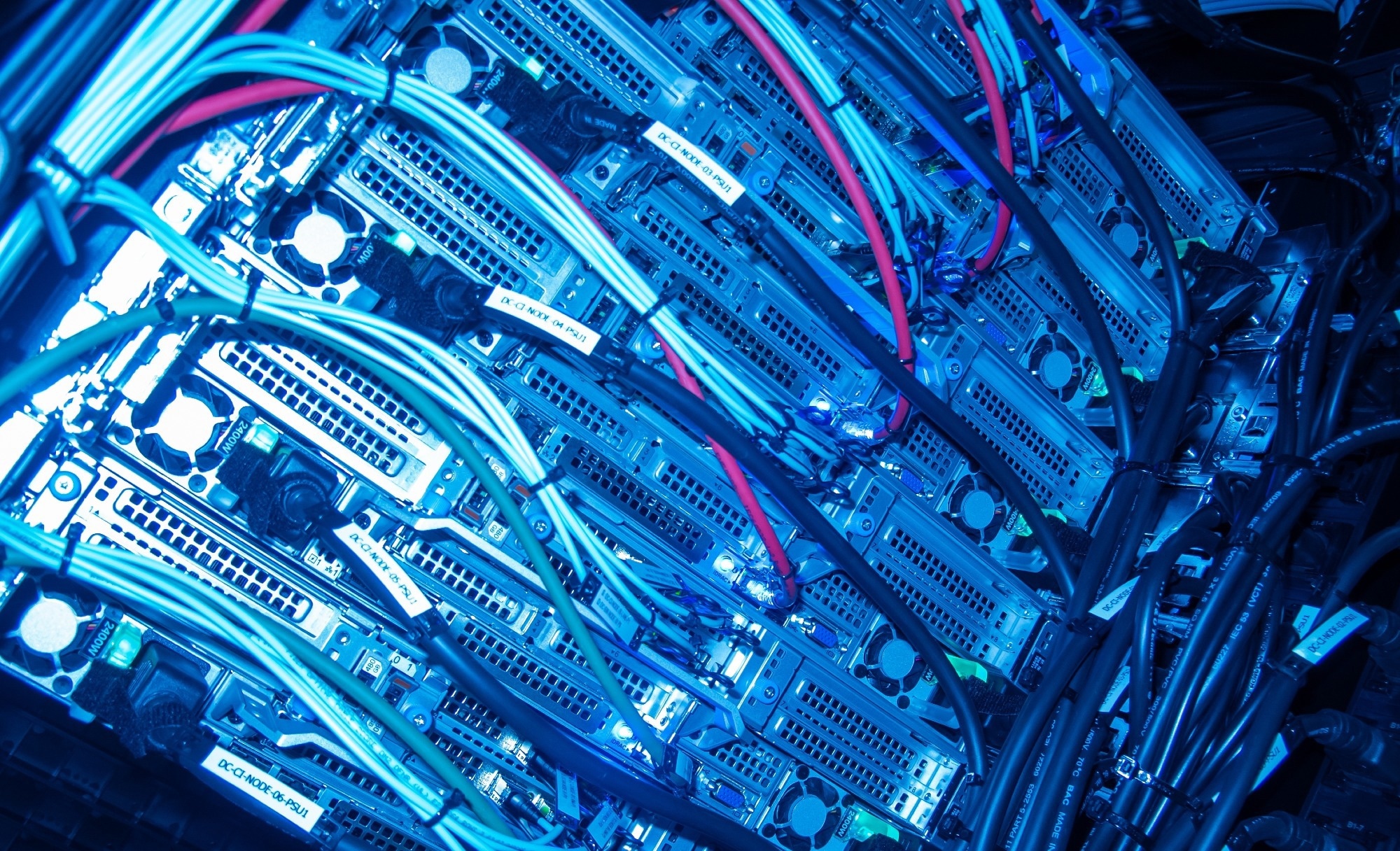

Study: Beyond Conventional Cooling: Advanced Micro/Nanostructures for Managing Extreme Heat Flux. Image Credit: panumas nikhomkhai/Shutterstock.com

Study: Beyond Conventional Cooling: Advanced Micro/Nanostructures for Managing Extreme Heat Flux. Image Credit: panumas nikhomkhai/Shutterstock.com

A recent review in Advanced Materials explores the improvement of thermal management in high-performance electronic devices through the use of micro- and nanostructures. The study examines the thermal challenges that come hand in hand with increasing power densities and component miniaturization.

The demand for efficient thermal management has increased substantially as electronic devices generate power densities approaching, and in some advanced power modules exceeding, 1000 W cm-2.

Conventional cooling methods, such as air and water cooling, are often inadequate due to their limited heat dissipation capacity. The result is overheating devices and a reduced overall lifespan.

For example, air cooling struggles to exceed 500 W per chip, while water-based systems require exceptionally high flow rates to manage heat effectively.

These issues have intensified interest in micro- and nanostructures, which, with their small size and large surface area, among other properties, can enhance heat transfer capabilities and design flexibility.

When integrated into chips, circuit boards, or cooling systems, nano- and microstructures can reduce thermal resistance and precisely control heat transfer.

Get all the details: Grab your PDF here!

Mechanisms of Enhanced Heat Transfer

The review emphasized the importance of both bio-inspired and engineered designs in nanostructures that can enhance thermal performance.

Through their dynamic physical structures, micro- and nanostructured “thermal metamaterials” can steer heat in preferred directions. In doing so, they enable tools such as thermal diodes and other devices for directional heat control.

Cooling strategies benefit from these structures:

- Conduction: Enhanced through nanostructured materials that can tailor and, in some cases, significantly increase thermal conductivity and directional heat transport. Materials such as graphene nanoribbons and carbon nanotubes exhibit exceptional thermal properties and support engineered, anisotropic heat spreading.

- Convection: Improved by optimized microchannel designs that enhance fluid flow, effectively transferring heat away from critical components, including emerging hydrodynamic designs that manipulate flow paths without additional pumping power.

- Phase Transition: Materials that absorb latent heat are crucial for controlling heat during processes such as melting and vaporization, which are essential in high-performance applications. Meanwhile, micro- and nanostructured surfaces influence bubble dynamics and capillary wicking, stabilizing and enhancing boiling and evaporation.

- Thermal Radiation: Increased when surfaces are tailored with specialized micro- and nanoscale features, enabling better management of heat loss through radiation, including directional and nonreciprocal thermal emitters for more controlled radiative cooling.

Additionally, researchers discussed the strengths and limitations of current design and manufacturing methods, highlighting challenges related to scalability, uniformity, and reproducibility. A key focus was the integration of micro- and nanoscale structures into thermal interface materials (TIMs) and heat sinks, which are essential for effective cooling.

Performance Improvements Through Novel Structure Design

The review demonstrates that micro- and nanostructures enhance thermal management by improving thermal conductivity and heat transfer rates, allowing engineered materials to outperform conventional alternatives.

Adding nanostructured surfaces to TIMs can reduce thermal interface resistance, improving cooling performance.

Bio-inspired designs use hierarchical features and optimized surface properties to enhance fluid flow and reduce thermal resistance.

For example, lotus leaf-inspired surfaces can tune wettability and liquid behavior, which, under the right conditions, can improve liquid-cooling performance by managing how droplets or films form and detach.

However, limitations in existing manufacturing techniques hinder large-scale adoption as achieving uniformity and reproducibility is difficult.

Applications of Micro/Nanostructures in Cooling Solutions

Micro- and nanostructures play an important role in developing TIMs for efficient heat transfer between electronic components.

Liquid-metal-based TIMs provide excellent thermal conductivity and are well-suited for high-performance cooling in applications with significant thermal loads.

Complementary phase-change materials (PCMs) can provide heat absorption capacities on the order of 300 kJ/kg, enabling effective buffering of transient thermal spikes.

These structures are integrated into heat sinks and cooling systems, where optimized designs and surface modifications improve heat dissipation. Micro- and nanoscale surfaces can enhance convective heat transfer coefficients, key to maintaining the reliability and lifespan of devices operating at high power densities.

Specially designed micro- and nanoscale structures can also modify fluid flow. By thinning the boundary layer, or guiding airflow, they can strengthen convective heat transfer, adjusting overall flow.

Conclusion and Future Directions

The findings suggest that micro- and nanostructures can substantially enhance cooling efficiency, supporting the development of the next generation of devices that can operate under extreme heat loads.

Future work should focus on developing new design strategies and advanced manufacturing techniques to fully harness the benefits of micro- and nanostructured materials, as well as using AI-assisted inverse design approaches to improve complex structures.

Challenges going forward will include improving on-chip cooling solutions, addressing corrosion, leakage, and cost issues in liquid-metal-based phase-change materials, as well as developing smart-wettability surfaces that adapt to changing operating conditions.

With concerns surrounding the heat management of data centers and devices, integrating micro- and nanoscale structures into thermal management systems could play a crucial role in the development of high-performance electronics in the future.

Journal Reference

Zhang, Y. et al. (2025, November). Beyond Conventional Cooling: Advanced Micro/Nanostructures for Managing Extreme Heat Flux. Advanced Materials, e04706. DOI: 10.1002/adma.202504706

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.