Nov 1 2008

A research team led by Iver Anderson is developing a cheaper and better way to make a titanium alloy powder that can be used to manufacture artificial joints. That could mean titanium joints, which can resist corrosion for the lifetime of a patient, could be affordable enough to replace stainless steel joints, which are commonly used today but can corrode after five years. And that could save patients the additional surgeries required to replace failing artificial joints.

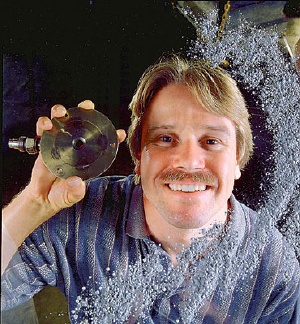

Iver Anderson of the U.S. Department of Energy's Ames Laboratory and Iowa State University is applying his expertise in atomization technology to develop new metals and a new technology for producing titanium alloy powder. Competitive grants from the Grow Iowa Values Fund, a state economic development program, are advancing Anderson's work and nine other research projects on campus. Photo courtesy of the U.S. Department of Energy's Ames Laboratory.

Iver Anderson of the U.S. Department of Energy's Ames Laboratory and Iowa State University is applying his expertise in atomization technology to develop new metals and a new technology for producing titanium alloy powder. Competitive grants from the Grow Iowa Values Fund, a state economic development program, are advancing Anderson's work and nine other research projects on campus. Photo courtesy of the U.S. Department of Energy's Ames Laboratory.

Anderson, a senior metallurgist for the U.S. Department of Energy's Ames Laboratory and an Iowa State adjunct professor of materials science and engineering, is hoping the new metals and new processing technology developed by his research team could lead to the creation of a new startup business called Iowa Powder Atomization Technologies and a new biomedical manufacturing industry in Iowa.

A grant from the Grow Iowa Values Fund, a state economic development program, will help advance the titanium powder project and nine others on the Iowa State University campus.

Iowa lawmakers agreed in 2005 to appropriate $5 million per year for 10 years to support economic development programs and research projects at Iowa's Regent universities. This year's funding was cut by 20 percent to provide additional state money for flood relief.

This is the fourth time Iowa State has awarded competitive grants from the Grow Iowa Values Fund. The grants are to go to research projects with high potential to boost the state's economic development efforts. The grants in this year's competition total $945,246 and range from $25,121 to the $171,499 supporting the titanium powder project.

The state grant will help Anderson and graduate students Andy Heidloff and Joel Rieken build a prototype atomizer to produce the titanium alloy powder.

With support from the U.S. Department of Energy and the Iowa State University Research Foundation, Anderson has already developed and patented a special pouring tube that can stand up to molten titanium and the atomization technology used to convert the molten metal into titanium powder.

With the help of the Grow Iowa Values Fund grant, "We're putting the pieces together to develop this prototype," Anderson said. "We want to demonstrate this technology to attract venture capital. This is a great chance to do something like spin off a company."

The other Grow Iowa Values Fund grants at Iowa State this year are:

- $143,814 to Atul Kelkar, professor of mechanical engineering; and Brent Shanks, professor of chemical and biological engineering. They're working with Innovative Energy Solutions Inc. of Ames to develop a continuous process that uses high temperatures and a combination of catalysts to convert waste plastics, crude oil sludge and tar sand into diesel fuel and other useful products.

- $125,550 to Jesse Goff, a professor of biomedical sciences in the College of Veterinary Medicine. Goff will work with two Ames companies -- Glycomyr and Heartland Assays -- to study whether products based on vitamin D3 can inhibit cancer cells.

- $117,150 to Victor Lin, a professor of chemistry and program director of Chemical and Biological Sciences for the U.S. Department of Energy's Ames Laboratory; and George Kraus, professor of chemistry and director of Iowa State's Institute for Physical Research and Technology. They'll work with a Muscatine company, Grain Processing Corp., to develop a catalytic process that efficiently converts renewable feedstocks into a chemical precursor to a common industrial polymer. The process could reduce industry's reliance on fossil fuels and some hazardous chemicals.

- $104,690 to Michael Olsen, an associate professor of mechanical engineering; Hui Hu, an assistant professor of aerospace engineering; and Z.J. Wang, a professor of aerospace engineering. They're working with J-TEC Associates Inc. of Cedar Rapids to develop the next generation of meters that measure exhaust flows from automobiles. The technology could help auto manufacturers develop engine technologies that minimize pollutants from biofuels.

- $79,050 to Michael Kessler, an assistant professor of materials science and engineering and an associate of the U.S. Department of Energy's Ames Laboratory; and Richard Larock, a Distinguished Professor of Chemistry and an associate of the Ames Laboratory. They're working with an Iowa company to develop resins based on corn, soy and other bio oils that can be used to manufacture fiberglass-reinforced products.

- $78,452 to David Grewell, assistant professor of agricultural and biosystems engineering; Kessler; Krishna Rajan, professor of materials science and engineering; William Graves, professor of horticulture; and Howard Van Auken, professor of management. They intend to work with five companies: Pella Corp. of Pella, Creative Composites of Brooklyn, Vermeer Corp. of Pella, Soy Works Corp. of Woodridge, Ill. and Freeman Industries of Tuchahoe, N.Y. They want to develop and commercialize plastic products made from corn and soy proteins, including wrapping for hay bales, pots for plants, construction panels, lubrication sticks and other products.

- $66,477 to Nicola Pohl, an associate professor of chemistry. Pohl will work with LuCella Biosciences Inc. of Ames to advance a carbohydrate synthesis technology for biologists and pharmaceutical scientists. The technology can fabricate a custom-order, complex carbohydrate molecule in 24 hours; current technology requires six to 12 months for the same molecule at a cost that can be 10 times higher than the new technology.

- $33,443 to Timothy Ellis, an associate professor of civil, construction and environmental engineering. Ellis will work with Envirotech Systems Inc. of Lawton to use rubber particles from scrap tires to develop a process to clean hydrogen sulfide from biogas and other gases.

- $25,121 to Gary Munkvold, an associate professor of plant pathology; and Alan Gaul, an assistant scientist in Iowa State's Seed Science Center. They'll work with Plasmer Seed of Ames to develop a low-temperature, plasma treatment for seeds that's designed to reduce pathogen levels in seeds and improve the effectiveness of seed treatment.