Reviewed by Sarah KellyOct 28 2025

Double-layer silicon electrodes show potential for the delivery of faster charging, more affordable electric vehicle batteries with longer lifespans.

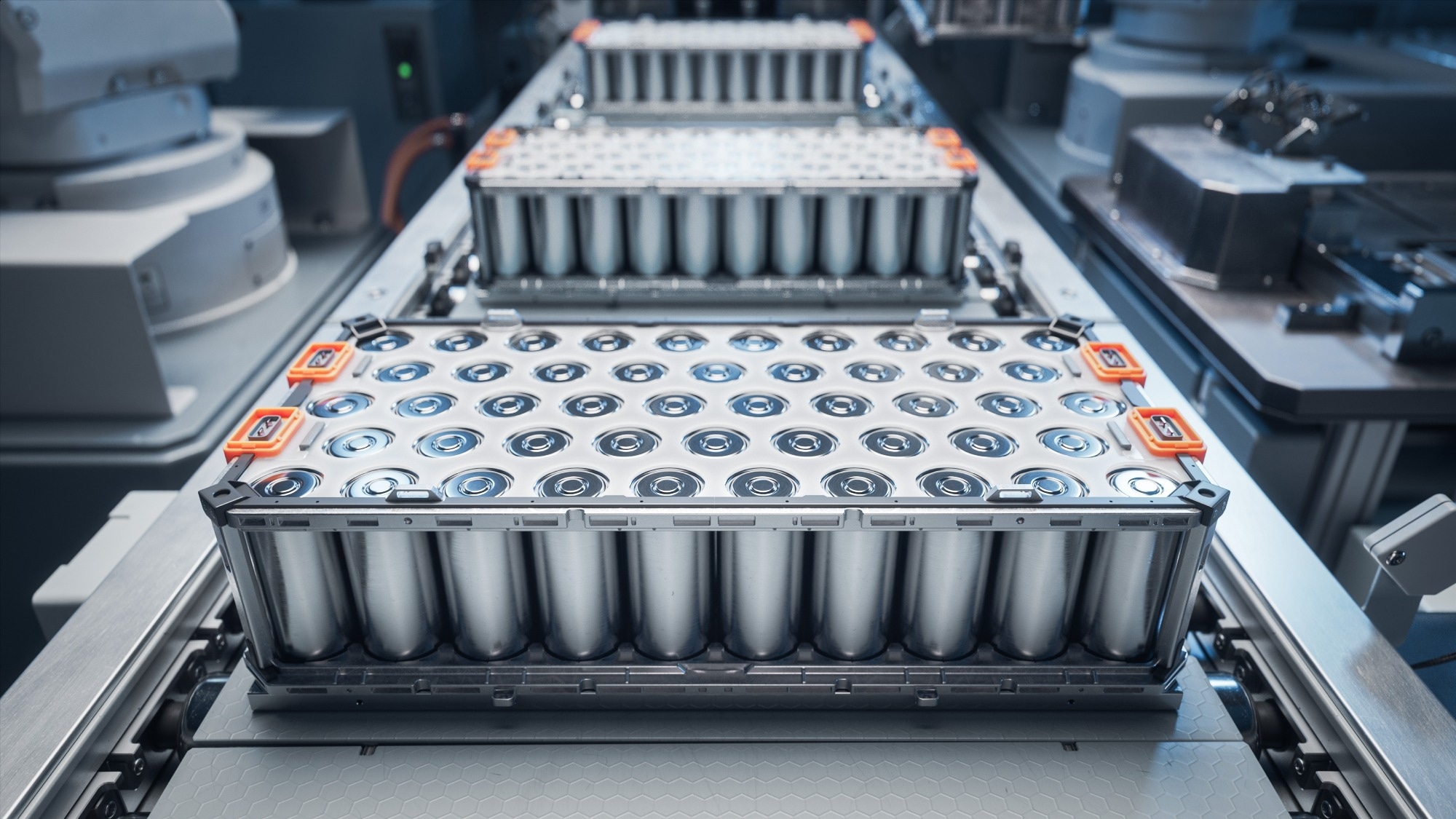

Study: Unravelling electro-chemo-mechanical processes in graphite/silicon composites for designing nanoporous and microstructured battery electrodes. Image credit: IM Imagery/Shutterstock.com

Study: Unravelling electro-chemo-mechanical processes in graphite/silicon composites for designing nanoporous and microstructured battery electrodes. Image credit: IM Imagery/Shutterstock.com

Researchers at Queen Mary University of London have revealed that a double-layer electrode configuration, informed by fundamental scientific principles via operando imaging, exhibits significant enhancements in the cyclic stability and rapid charging capabilities of automotive batteries, with considerable potential to lower costs by 20-30 %. The study was published in Nature Nanotechnology.

In this research, the team presents a double-layer design for silicon-based composite electrodes aimed at addressing significant challenges associated with silicon-based electrodes. This represents a significant advancement with considerable potential for the development of next-generation high-performance batteries.

The advancement of automotive batteries has been propelled over the past 20 years by the growing demand for extended driving range and rapid charging since the advent of electric vehicles (EVs).

Silicon electrodes offer a theoretical capacity that is 10 times greater and provide faster charging. However, their widespread use is limited by significant volume fluctuations of up to 300 % during charge and discharge cycles, resulting in rapid degradation and a limited lifespan.

Using multiscale multimodal operando imaging techniques, the researchers have uncovered remarkable insights into the electro-chemo-mechanical dynamics of graphite/silicon composite electrodes.

A new double-layer architecture has been proposed based on these enhanced mechanistic insights. It tackles critical challenges in material design and demonstrates considerably higher capacity and reduced degradation than traditional formulations.

In this research, we visualize for the first time the interaction between microstructural design and electro-chemo-mechanical performance across various length scales, from individual particles to complete electrodes, by incorporating multimodal operando imaging techniques.

Dr. Xuekun Lu, Study Lead, Queen Mary University of London

Dr. Lu believes the study will provide new opportunities for creating 3D composite electrode architectures, pushing the boundaries of energy density, charging speed, and cycle life for automotive batteries, potentially accelerating the large-scale adoption of EVs.

High silicon anodes are an important technology pathway for high energy density batteries in applications like Automotive. This study offers a much deeper understanding of the way in which their microstructure affects their performance and degradation, and will provide a basis for better battery design in the future.

Professor David Greenwood, CEO of the WMG High Value Manufacturing Catapult Center

Journal Reference:

Lu, X., et al. (2025) Unravelling electro-chemo-mechanical processes in graphite/silicon composites for designing nanoporous and microstructured battery electrodes. Nature Nanotechnology. doi.org/10.1038/s41565-025-02027-7.