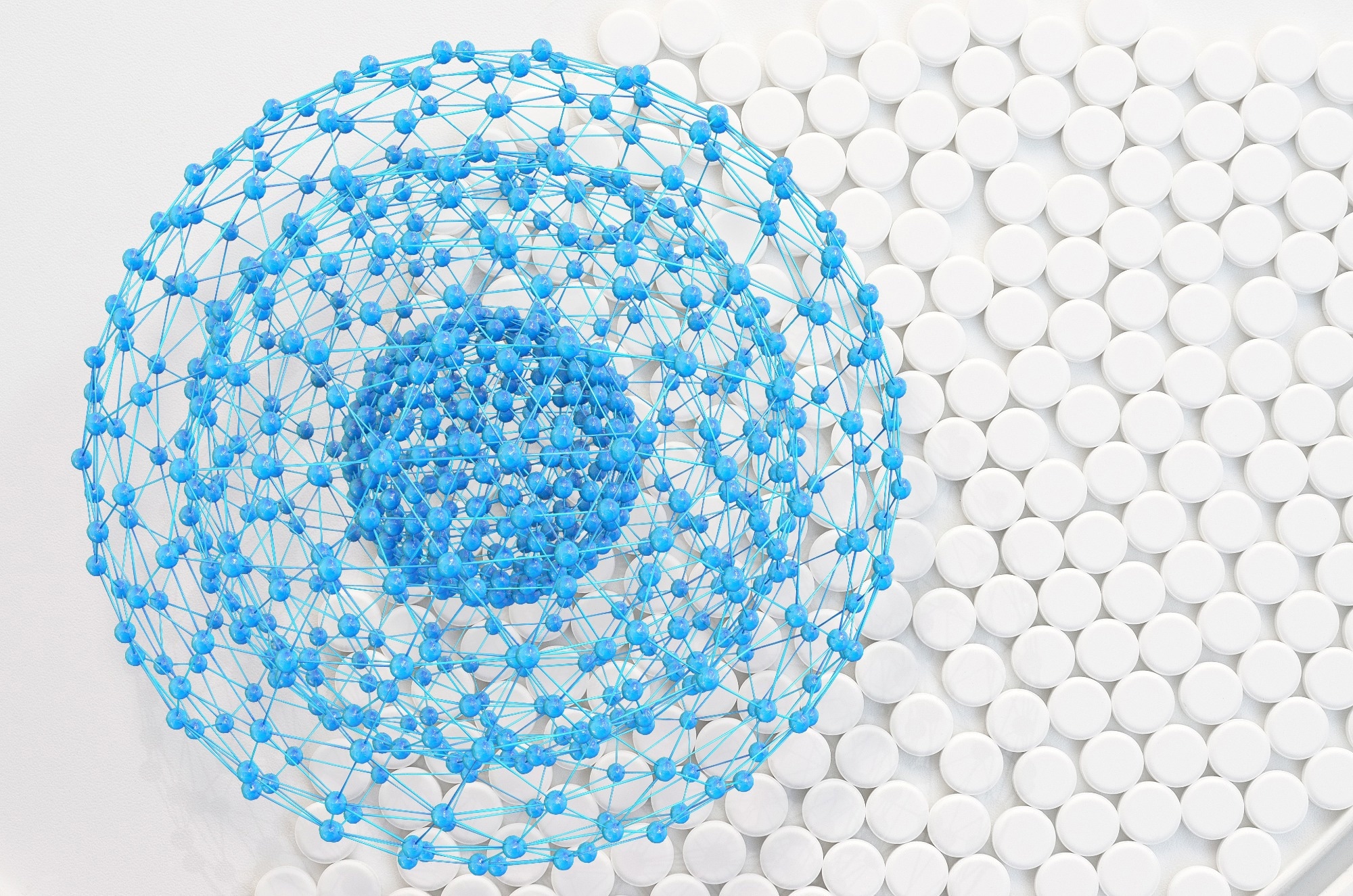

Nanocatalysts have revolutionized chemical research by enabling faster and more selective reactions. Their unique properties enhance efficiency and sustainability across diverse applications.

Image Credit: xrender/Shutterstock.com

Catalysts accelerate chemical reactions by lowering the activation energy without being consumed, increasing reaction rates, improving selectivity, and reducing energy consumption.

Building on these principles, nanocatalysts have emerged as a new class of catalysts that leverage nanoscale properties to achieve enhanced performance and efficiency in chemical reactions.

At the nanometer scale, interactions between atoms and molecules can differ significantly from those in bulk materials, leading to altered electronic structures, modified surface energies, and enhanced interaction with reactants. These characteristics enable nanocatalysts to facilitate complex transformations, stabilize reactive intermediates, and promote reaction pathways often inaccessible to conventional catalysts.

Nanocatalysts can operate under milder reaction conditions, improving overall process efficiency and reducing energy requirements. Their versatility also allows for integration into diverse catalytic systems across various chemical, environmental, and energy-related applications.1

How Nanocatalysts Differ from Traditional Catalysts?

Nanocatalysts differ from conventional catalysts primarily due to their nanoscale dimensions and unique physicochemical properties.

Traditional catalysts generally exhibit lower surface areas, limited reactivity, and reduced durability over repeated use. In contrast, nanocatalysts offer:

- Higher surface area-to-volume ratio, resulting in more active sites and faster reaction rates.

- Size-dependent properties, including tunable selectivity and activity through controlled synthesis.

- Tailored nanostructures, such as core–shell configurations, which enhance performance and stability.

- Greater sustainability, as they can be synthesized from earth-abundant materials, reused efficiently, and aligned with renewable resource utilization.

These distinctions enable nanocatalysts to exhibit higher catalytic activity, improved selectivity, longer operational lifetimes, and lower energy demand, making them more efficient and environmentally compatible than traditional catalysts.2

Types of Nanocatalysts

Homogeneous Nanocatalysts

Homogeneous nanocatalysts function in the same phase as their reactants, often existing as nanoparticles dispersed in solution.

A major challenge in these systems is nanoparticle aggregation, which reduces surface area and diminishes catalytic efficiency. To prevent clustering, nanoparticles are often coated with long-chain molecules that stabilize them in solution. However, this can sometimes block active sites and reduce activity. Recovering homogeneous nanocatalysts from solution is also difficult, hindering reuse and affecting process sustainability.

Click here to download a PDF copy of this page

A common example is palladium nanoparticles dispersed in an organic solvent, which is widely employed in hydrogenation and carbon–carbon coupling reactions.

Heterogeneous Nanocatalysts

Heterogeneous nanocatalysts operate in a different phase than the reactants, typically as solids or nanoparticles immobilized on solid supports. This phase separation facilitates easy recovery and reuse through filtration or other mechanical methods, improving operational efficiency and reducing waste.

For example, titanium dioxide nanoparticles supported on silica are widely used in photocatalytic oxidation reactions, demonstrating high activity and stability in environmental and chemical processes.

Single-Atom Catalysts

Single-atom catalysts represent a breakthrough within heterogeneous nanocatalysts, combining features of both homogeneous and heterogeneous systems.

SACs consist of isolated single-atom active sites, offering high reactivity similar to homogeneous catalysts while maintaining the stability, recoverability, and separation advantages of heterogeneous catalysts. In addition, they provide a promising pathway to maximize catalytic efficiency, selectivity, and sustainability in advanced chemical processes.

Examples include Rh/ZnO and Rh/CoO SACs for olefin hydroformylation, Pt/Al2O3 SACs for hydrosilylation, and M–N–C SACs (M = Fe, Co) for C–H bond activation.2,3

Advancing Green Chemistry

Biological Synthesis Approaches

Nanocatalysts can be synthesized through biological or green routes, serving as eco-friendly alternatives to conventional chemical and physical methods. This sustainable, bottom-up approach utilizes microorganisms and biomolecules, such as enzymes, proteins, and sugars, to reduce metallic ions into nanoparticles, resulting in catalysts with high surface areas, enhanced activity, and improved stability.

For instance, Pseudomonas stutzeri AG259 (a gram-negative bacterium) helps produce silver nanoparticles through NADH-dependent reductase activity. This reduces reliance on toxic chemicals, although challenges remain in controlling particle size, shape, and distribution with precision.2,4

Biodiesel Production

Traditional biodiesel production via transesterification using homogeneous catalysts faces several challenges, including complex product separation, high water consumption, and environmental pollution from liquid waste.

Nanocatalysts offer a promising solution by providing enhanced catalytic activity and greater surface area, improving reaction efficiency. This approach combines the sustainability of solid heterogeneous catalysts with improved reaction rates and efficiency, overcoming limitations of conventional methods.

Recent research has demonstrated that solid base nanocatalysts, such as KF/CaO, can achieve biodiesel yields exceeding 96%. This catalyst effectively converts oils with high acid content into biodiesel, featuring particle sizes ranging from 30 to 100 nanometers with a porous structure that enhances efficiency. The catalyst forms a new crystal structure, KCaF3, which enhances both activity and stability while facilitating improved interaction between the catalyst and reactants. 5,6

Wastewater Treatment

Conventional wastewater treatment methods are often ineffective against halogenated organic compounds (HOCs), which are persistent and toxic pollutants commonly used as solvents and additives in the pharmaceutical and technology industries, posing serious health risks such as cancer and genetic damage.

Nanocatalysts offer a promising alternative by enabling decentralized selective dehalogenation, specifically targeting halogen atoms in HOCs. This approach provides a more efficient, cost-effective, and environmentally sustainable solution, reducing disposal costs and overcoming the limitations of traditional treatment techniques.

A study published in Water Research demonstrated that palladium nanoparticles on nitrogen-doped graphene (Pd/NG) effectively degraded halogenated compounds, such as TBBPA and triclosan, outperforming palladium on undoped graphene (Pd/G) and commercial carbon (Pd/C). DFT calculations further showed that TBBPA degradation on Pd/NG required lower activation energy (2.7 eV vs. 2.8 eV), demonstrating the superior catalytic activity of nanocatalysts against HOCs.7

Hydrogen Fuel Production

Nanocatalysts play a crucial role in hydrogen production for fuel cells, offering a more cost-effective alternative to electrolysis, which currently accounts for less than 5% of global hydrogen production due to high energy costs.

Recently, cobalt–platinum (Co–Pt) alloy nanoparticles with uniform sizes of 3–4 nm were developed through simple thermal treatment, combining the ease of impregnation methods with precise control over size and morphology to enhance catalytic performance. These Co–Pt nanocatalysts enhanced hydrogen generation by stabilizing cobalt atoms within the platinum matrix, thereby increasing active sites and catalytic efficiency, and achieving hydrogen evolution rates significantly higher than those of pure cobalt nanoparticles. They reduced activation energy and improved stability under reaction conditions.8

In another study, green hydrothermal synthesis using tobacco stem extract produced Co–Sb nanoparticles that achieved hydrogen generation rates of 5618 ml min?¹ g?¹, surpassing those of pure cobalt nanoparticles. The 1 wt% Sb doping lowered the activation energy from 35.5 to 30.9 kJ mol?¹, enhancing the efficiency of the water-splitting reaction. These nanocatalysts enhanced proton exchange membrane (PEM) fuel cell performance, achieving peak power densities of 137.3 mW cm?², which demonstrates the potential of biologically assisted synthesis for sustainable and high-performance hydrogen production.9

Conclusion

Nanocatalysts provide enhanced reactivity, high surface area, and improved selectivity, making them central to modern catalytic science. However, challenges such as controlling particle size, shape, and distribution, as well as ensuring stability and scalability, limit their widespread application. Ongoing research continues to address these issues, offering the potential for sustainable solutions across diverse chemical and energy-related processes.

References and Further Reading

- Sen, A., Oswalia, J., Yadav, S., Vachher, M., & Nigam, A. (2023). Recent trends in nanozyme research and their potential therapeutic applications. Current Research in Biotechnology, 7, 100205. https://doi.org/10.1016/j.crbiot.2024.100205

- Baruwa, A., Gbadeyan, O.J. & Permaul, K. (2025). Revolutionizing biotechnology: the impact of nanocatalysts and nanomaterials—a comprehensive review. Discov Mater 5, 89. https://doi.org/10.1007/s43939-025-00269-9

- Wang, Y., He, X., Huang, K., & Cheng, N. (2024). Nanozyme as a rising star for metabolic disease management. Journal of Nanobiotechnology, 22(1). https://doi.org/10.1186/s12951-024-02478-5

- Kesavan, A., Rajakumar, T., Karunanidhi, M., Ravi, A., Vivekanand, P. A., Kamaraj, P., Arumugam, N., Hari Kumar, S., Perumal, K., Djearamane, S., Aminuzzaman, M., Wong, L. S., & Kayarohanam, S. (2024). A Comparative analysis of PESC and PPSC copolyesters: Insights into viscosity, thermal behavior, crystallinity, and biodegradability. Heliyon, 10(2), e24728. https://doi.org/10.1016/j.heliyon.2024.e24728

- Thakur, K., Attri, C., & Seth, A. (2021). Nanocarriers-based immobilization of enzymes for industrial application. 3 Biotech, 11(10). https://doi.org/10.1007/s13205-021-02953-y

- Gómez, J., I., J., Hornos, F., & Hueso, J. L. (2023). Enzyme–Iron Oxide Nanoassemblies: A Review of Immobilization and Biocatalytic Applications. Catalysts, 13(6), 980. https://doi.org/10.3390/catal13060980

- Li, L., Gong, L., Wang, Y., Liu, Q., Zhang, J., Mu, Y., & Yu, H. (2016). Removal of halogenated emerging contaminants from water by nitrogen-doped graphene decorated with palladium nanoparticles: Experimental investigation and theoretical analysis. Water Research, 98, 235-241. https://doi.org/10.1016/j.watres.2016.04.024

- Yoo, T. Y., Lee, J., Kim, S., Her, M., Kim, S.-Y., Lee, Y.-H., Shin, H., Jeong, H., Sinha, A. K., Cho, S.-P., Sung, Y.-E., & Taeghwan Hyeon. (2023). Scalable production of an intermetallic Pt–Co electrocatalyst for high-power proton-exchange-membrane fuel cells. Energy & Environmental Science, 16(3), 1146–1154. https://doi.org/10.1039/d2ee04211h

- Ekinci, A., Sahin, Ö., Turgut, S., & Baytar, O. (2025). Eco-friendly nanocatalysts for hydrogen generation via sodium borohydride hydrolysis and enhanced fuel cell applications. International Journal of Hydrogen Energy, 143, 791-801. https://doi.org/10.1016/j.ijhydene.2025.03.454

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.