Maintaining clean air is essential for industries operating in strictly controlled environments, including cleanroom particle monitoring, environmental control, filter and compliance testing, indoor air quality assessment, quality assurance (QA) programs, and more.

To ensure cleanliness of cleanrooms, global standards have been established by organizations such as the International Organization for Standardization (ISO), the U.S. Food and Drug Administration (FDA), and the European Medicines Agency (EMA). These standards require real-time surveillance of key parameters, including airborne particle counts, temperature, humidity, and pressure, particularly in cleanroom classification environments.

Cubic, the leading manufacturer of gas sensors and gas analyzers, delivers advanced air particle monitoring solutions for critical applications in semiconductor, lithium-ion battery manufacturing, the pharmaceutical industry, and flat panel display production cleanrooms. With a focus on precision, safety, and energy efficiency, the Cubic particle counter is engineered to support strict process control and regulatory compliance across demanding industrial environments.

Features

- Selectable between 6 particle channels >0.3, >0.5, >1.0, >2.5, >5.0 & >10 microns.

- Selectable output units, pcs/L, pcs/ 28.3 LPM and pcs/m³.

- RJ45 MQTT, RS485 Modbus RTU or 4-20 mA analog communications available (optional).

- Color touchscreen for device operations and settings (optional).

- Integrated temperature & relative humidity sensor (optional).

- Built-in flow control system and pump/ fan for 2.83 LPM, 28.3 LPM stable sampling.

- DC-powered and rechargeable Li-battery (optional) for power supply.

- Compliance with ISO 21501-4:2018 and CE standards.

Benefits

- Reduced manual errors with pre-set continuous monitoring.

- Monitoring software supports real-time data log on PC for audit data trail.

- Easy and friendly user interface with touch display (optional).

- Real-time light and sound alert of contamination problems.

- 99.999% HEPA-filtered exhaust and chemically resistant aluminum alloy enclosure.

- Affordable options for site monitoring and troubleshooting.

- Built-in pump/ fan simplifies installation and operation and is easy to use in various applications.

Applications

- Controlled environment/ sensitive area/ process particle monitoring system.

- Portable or remote/fixed particle monitoring.

- Air cleanliness trend analysis.

- Cleanroom assessment and ISO 14644-1 grading.

Accessory

Isokinetic sampling head. Image Credit: Cubic Sensor and Instrument Co. Ltd

Sampling hose (optional). Image Credit: Cubic Sensor and Instrument Co. Ltd

Power adapter and adapter plug (optional). Image Credit: Cubic Sensor and Instrument Co. Ltd

Table Overview for Cubic Optical Particle Counters

Source: Cubic Sensor and Instrument Co.,Ltd

Model

No. |

Output

Channels |

Flow Rate (L/min) |

Output

Unit |

Communication |

Display |

Power

Supply |

OPC-6510DS OPC-6510DS |

0.3 μm, 0.5 μm,

1.0 μm, 5.0 μm,

10 μm |

28.3 |

pcs/28.3L,

pcs/m3 |

RJ45 MQTT

RS485 ModBus |

Yes |

24 V DC |

OPC-6510 OPC-6510 |

0.3 μm, 0.5 μm,

1.0 μm, 5.0 μm,

10 μm |

28.3 |

pcs/28.3L,

pcs/m3 |

RS485

ModBus |

No |

24 V DC |

OPC-6511DS OPC-6511DS |

0.3 μm, 0.5 μm,

1.0 μm, 5.0 μm,

10 μm |

28.3 |

pcs/28.3L,

pcs/m3 |

RJ45 MQTT

RS485 ModBus |

Yes |

Battery or

24 V DC |

OPC-6303DS OPC-6303DS |

0.3 μm, 0.5 μm,

1.0 μm, 2.5 μm,

5.0 μm, 10 μm |

2.83 |

pcs/m3,

pcs/L,

pcs/28.3L |

4-20 mA

RJ45 MQTT

RS485 ModBus |

Yes |

12 V DC |

OPC-6303M OPC-6303M |

0.3 μm, 0.5 μm,

1.0 μm, 2.5 μm,

5.0 μm, 10 μm |

2.83 |

pcs/m3,

pcs/L,

pcs/28.3L |

4-20 mA

RJ45 MQTT

RS485 ModBus |

No |

12 V DC |

28.3LPM Optical Particle Counter

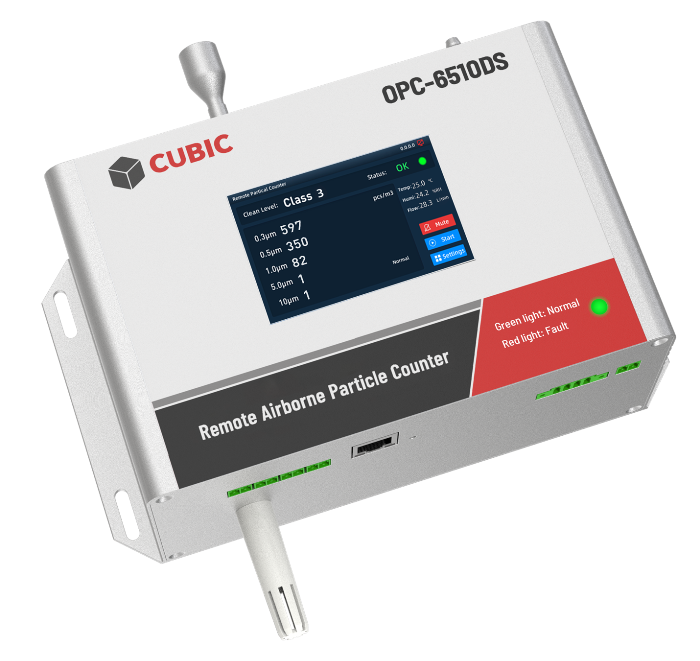

OPC-6510DS

Cubic optical particle counter OPC-6510DS employs light scattering technology to accurately detect particles of various sizes within a specified volume of air. Featuring a unique laser particle counter module, a consistent RPM fan, and a well-designed ultrasonic flow sensor, OPC-6510DS maintains a stable and high gas sampling rate reaching 1 CFM.

OPC-6510DS provides particulate output across five channels for size 0.3 μm, 0.5 μm, 1.0 μm, 5.0 μm, and 10 μm. The device supports long operation duration, enabling continuous particle monitoring.

In addition to high-precision detection and continuous monitoring capabilities, OPC-6510DS also features a 3.5-inch color touch screen for real-time data display. The audible and visual alarm system are also included in the device providing on-site warnings timely.

Cubic OPC-6510DS can achieve real-time monitoring and online data transmission based on RS485 ModBus RTU and RJ45 MQTT communication.

Image Credit: Cubic Sensor and Instrument Co. Ltd

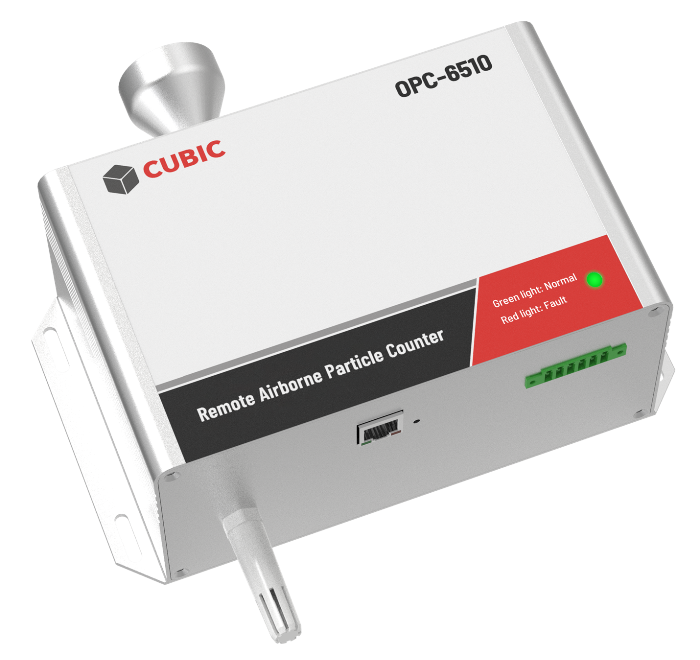

OPC-6510

Cubic remote online particle counter OPC-6510 adopts light scattering technology for high-accuracy detection. The device provides multi-channel output of >0.3μm, >0.5μm, >1.0μm, >5.0μm, >10μm in pcs/28.3L and pcs/m3. The built-in fan ensures continuous and constant sampling. With RS485 Modbus RTU communication interface, OPC-6510 ensures remote online monitor of particles.

Image Credit: Cubic Sensor and Instrument Co. Ltd

OPC-6511DS

Cubic portable particle counter OPC-6511DS utilizes advanced light scattering technology to accurately measure particulates at sizes of 0.3μm, 0.5μm, 1.0μm, 5.0μm, and 10μm. Featuring a communication interface based on RS485 Modbus RTU and RJ45 MQTT, and an intuitive 7-inch touch screen that provides real-time measurement results. Its built-in rechargeable lithium battery enhances efficiency for different applications by extending battery life. With its precise detection capabilities and portability, OPC-6511DS greatly enhances the user experience, making it an ideal choice for applications in cleanrooms, medical manufacturing, semiconductors, and more.

Image Credit: Cubic Sensor and Instrument Co. Ltd

2.83LPM Optical Particle Counter

OPC-6303DS

Cubic wall-mounted particle counter OPC-6303DS uses light-scattering technology with a flow rate of 2.83 LPM and a 3.5-inch touch display. It provides real-time measurements of particle quantities ranging from 0.3 to 10 microns, presented in pcs/m³, pcs/28.3 LPM, or pcs/L. The device monitors cleanroom environments in accordance with ISO standards. Additionally, it supports communication via 4-20 mA analog signals, RS485 Modbus RTU, and RJ45 MQTT, making OPC-6303DS ideal for remote continuous monitoring.

Image Credit: Cubic Sensor and Instrument Co. Ltd

OPC-6303M

Cubic online particle counter OPC-6303M utilizes light scattering technology and a pump-suction sampling method to accurately detect and quantify airborne particles of different sizes. It provides real-time data on particle concentrations across six channels: 0.3μm, 0.5μm, 1.0μm, 2.5μm, 5.0μm, and 10μm, measured in PCS/m³, PCS/L, or PCS/28.3L. OPC-6303M is designed to deliver high-performance monitoring for various cleanroom applications where GMP standards must be met.

Image Credit: Cubic Sensor and Instrument Co. Ltd