Standard nanobubble (NB) water was examined in conjunction for reference. When compared to the usage of NBs alone, flotation findings of a modeled high-ash fine coal indicated that employing water combining PCNBs and PAC resulted in reduced combustion with a consequent decrease in ash extraction.

Strategies to Improve the Efficiency of High Ash Fine Coal

With depleting ore supplies and rising demand for consumer coal throughout the globe, coal producers have resorted to using foam extraction to create higher amounts of decreased carbon ore deposits, which is based on differences in the surface qualities of anthracite and sludge materials.

Several attempts have been made in the industry to improve the productivity and efficiency of flotation extraction of high ash fine coal.

Researchers have found that clay fine coal flotation with the use of sterile normal saline can increase combustion retrieval from 55 percent in freshwater to 87 percent in saltwater, while concurrently increasing the recuperation of unwanted gravels by 34 percent.

Nanobubbles (NBs) have recently gained a considerable deal of interest in the field of foam floating. The formation of NBs (negatively charged aggregates) occurs in pure water.

They have the potential to rapidly connect to water-insoluble soil surfaces and thereby improve buoyancy efficiency and retrieval performance by stimulating the agglomeration of tiny and nanosized mineral grains through capillary forces and by serving as nuclei for traditional flotation-sized droplets.

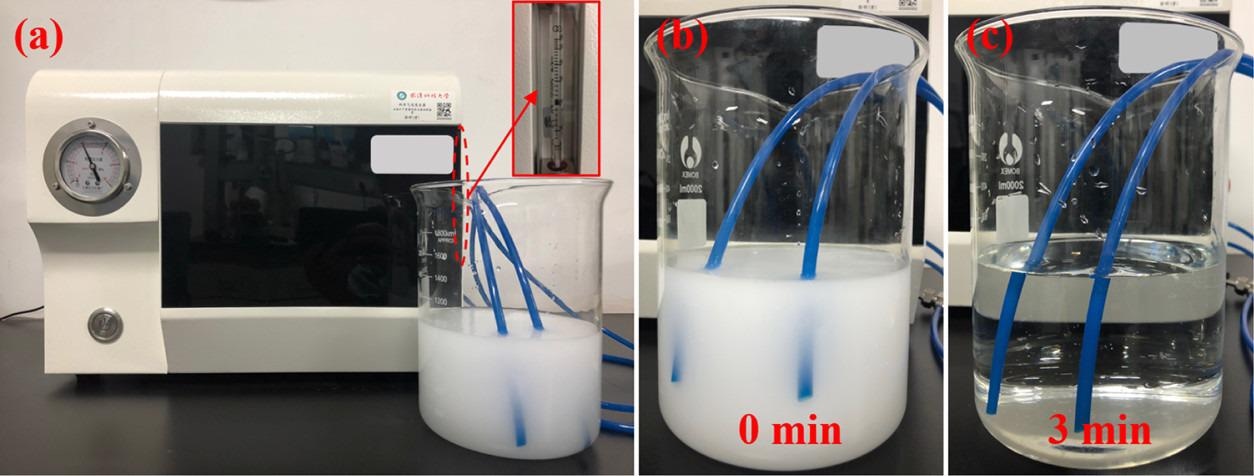

NBs generation system in action (a) and the “milky” solution after standing for 0 (b) and 3 min (c). © Li, P., Zhang. et al. (2022).

Addition of Polyaluminum Chloride (PAC) to Nanobubble (NB)

According to previous research, employing water-containing NBs improved combustible recovery by increasing the relative size of smaller fine powders in the vicinity of NBs and clay particulate entrapment and concentrate restoration. In the same study, PAC was introduced directly to NB aqueous flotation. The results showed that although this technique reduced combustible recovery by affecting the hydrophobic character of coal particles on the surface, it did reduce excessive kaolinite entrapment.

This kind of approach was either unfeasible or had the disadvantage of not being capable of achieving high fine coal retrieval while also restricting the amount of gangue entrapped at the same time. Improved technologies for separating fine coal with high ash content are urgently required.

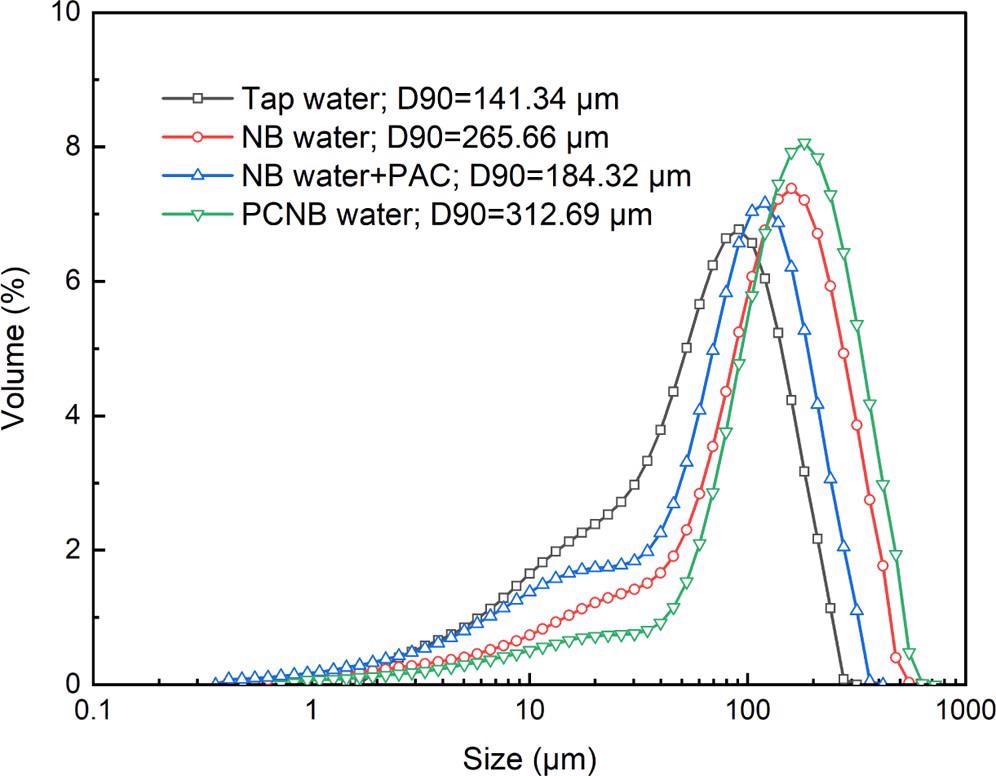

Size distribution of clean coal in different waters with and without PAC. © Li, P., Zhang. et al. (2022).

Advantages of Positively Charged Nanobubbles (PCNBs) in Mineral Flotation

Whereas the relevance of NBs in material recovery is becoming more widely recognized, positively charged nanobubbles (PCNBs), which are made by adding ions and salts to an NB generator, have exhibited potential in sewage treatment.

The ionic interactions between the negative pigment ingredients and positive NBs, whose surface charge was reversed by inserting coagulant Al2(SO4)3, were ascribed by some studies to the accelerated dye degradation rate of deep green Rit pigment employing positively charged NBs (PCNBs).

Positively charged microbubbles have also been reported to improve the float recovery of ultrafine reduced coal.

The researchers recommend employing PCNBs and PAC to separate high-ash fine coal in this investigation. Given PAC's capacity to minimize clay absorption and coal's negative surface charge at normal pH,5,10 it was hypothesized that after inverting the charge, NBs would be better able to enhance flotation recovery and a reasonable concentration grade could be sustained in the vicinity of PAC.

Research Findings and Conclusion

According to the present research, water containing PCNBs and PAC may be simply created by adding PAC to an NB synthesizer. Compared to employing pure NB water, agitation of a modeled high-ash fine coal with PCNBs enhanced the positive impact of NBs on combustible recovery while simultaneously reducing ash recovery.

The former was associated with increased coal particle aggregation caused by PCNBs, while the latter was shown by a lower degree of absorption in the existence of PAC.

It was also discovered that PAC might break coal aggregates caused by NBs, allowing trapped kaolinite particles to be released with less entrapment. Overall, the PCNBs with PAC flotation technology seem viable for separating high-ash fine coal effectively.

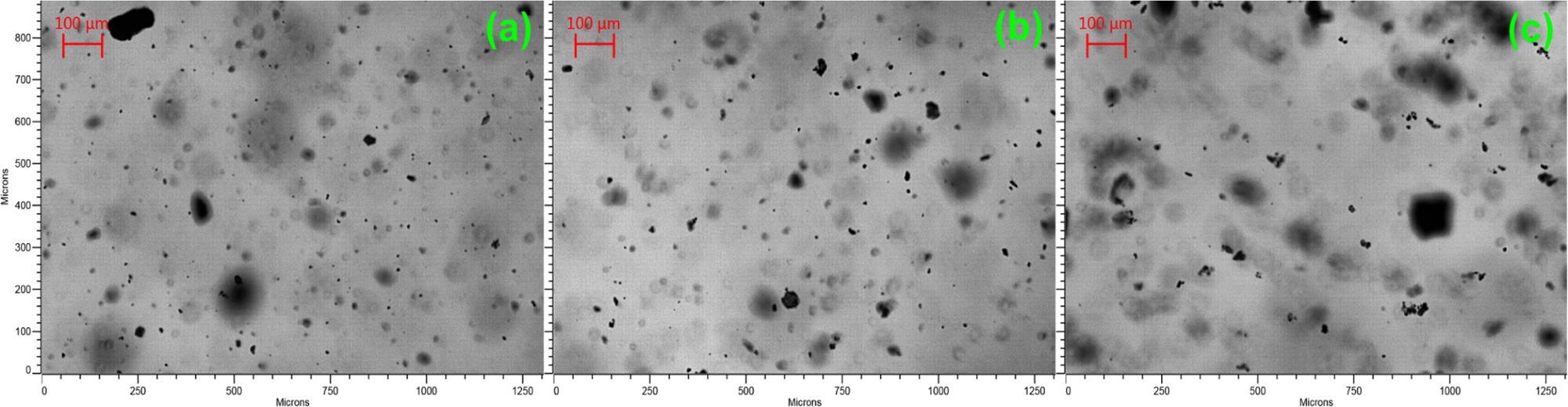

PVM morphology of clean coal particles/flocs in tap water (a), NB water, (b) and PCNB water (c). © Li, P., Zhang. et al. (2022).

Reference

Li, P., Zhang. et al. (2022). Effective Separation of High-Ash Fine Coal Using Water Containing Positively Charged Nanobubbles and Polyaluminum Chloride. ACS Omega. Available at: https://pubs.acs.org/doi/10.1021/acsomega.1c05751

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.