Scientists at Los Alamos National Laboratory and Berkeley Lab, the University of California have developed a nanoscale method for testing irradiated substances that offer macroscale materials - strength characteristics.

This method could lead to the fabrication of novel materials for the nuclear sector and to lower the quantity of material needed for checking the currently functional facilities.

Andrew Minor, an associate professor in the materials science and engineering department at UC Berkeley stated that it is possible to obtain genuine properties from irradiated specimens of the order of 400 nm in diameter using nanoscale testing that finds application in the field of nuclear materials.

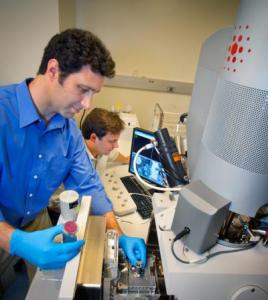

Berkeley Lab scientist Andy Minor (left) and Peter Hosemann have devised a nanoscale testing technique for irradiated materials to provide macroscale materials-strength properties

Berkeley Lab scientist Andy Minor (left) and Peter Hosemann have devised a nanoscale testing technique for irradiated materials to provide macroscale materials-strength properties

In this study, Minor and his team performed compression tests of copper specimens using high-energy protons to determine how radiation damage affects copper’s mechanical properties. The team used special in situ mechanical testing equipment to study the deformation and its localization to a few atomic planes at nanoscale resolution.

Three-dimensional defects generated as a result of radiation within copper can obstruct the movement of one-dimensional defects, known as dislocations and this interaction makes irradiated substances brittle in nature. It changes the material’s withstanding capacity before it breaks ultimately. The translation of nanoscale strength values into bulk characteristics helps designers of nuclear reactors to obtain the right materials for engineering parts in nuclear plants.

An assistant professor in the nuclear engineering department at UC Berkeley, Peter Hosemann, stated that the small-scale testing could aid in improving the life of a nuclear reactor. He added that with a small specimen, they can solve any safety problems that arise due to handling of the test material. He added that using a smaller specimen it is possible to measure the properties of the material used in a 40-year-old nuclear plant to ensure that the new structure will remain durable in the future too.

Minor adds that by knowing the role played by defects on the mechanical properties of materials for designing nuclear reactors will enable us to fabricate materials with resistance to radiation, paving the way for safer and advanced nuclear technologies.