Reviewed by Lexie CornerJun 11 2025

A study published in Nature Communications Engineering reports a non-destructive method for examining structural deformations in nanosheets used in advanced electronic devices. Using a highly focused 12-nanometer X-ray beam, researchers identified two distinct deformation processes occurring at different length scales.

These findings improve understanding of nanosheet behavior and could support the design of more reliable nanoscale electronics.

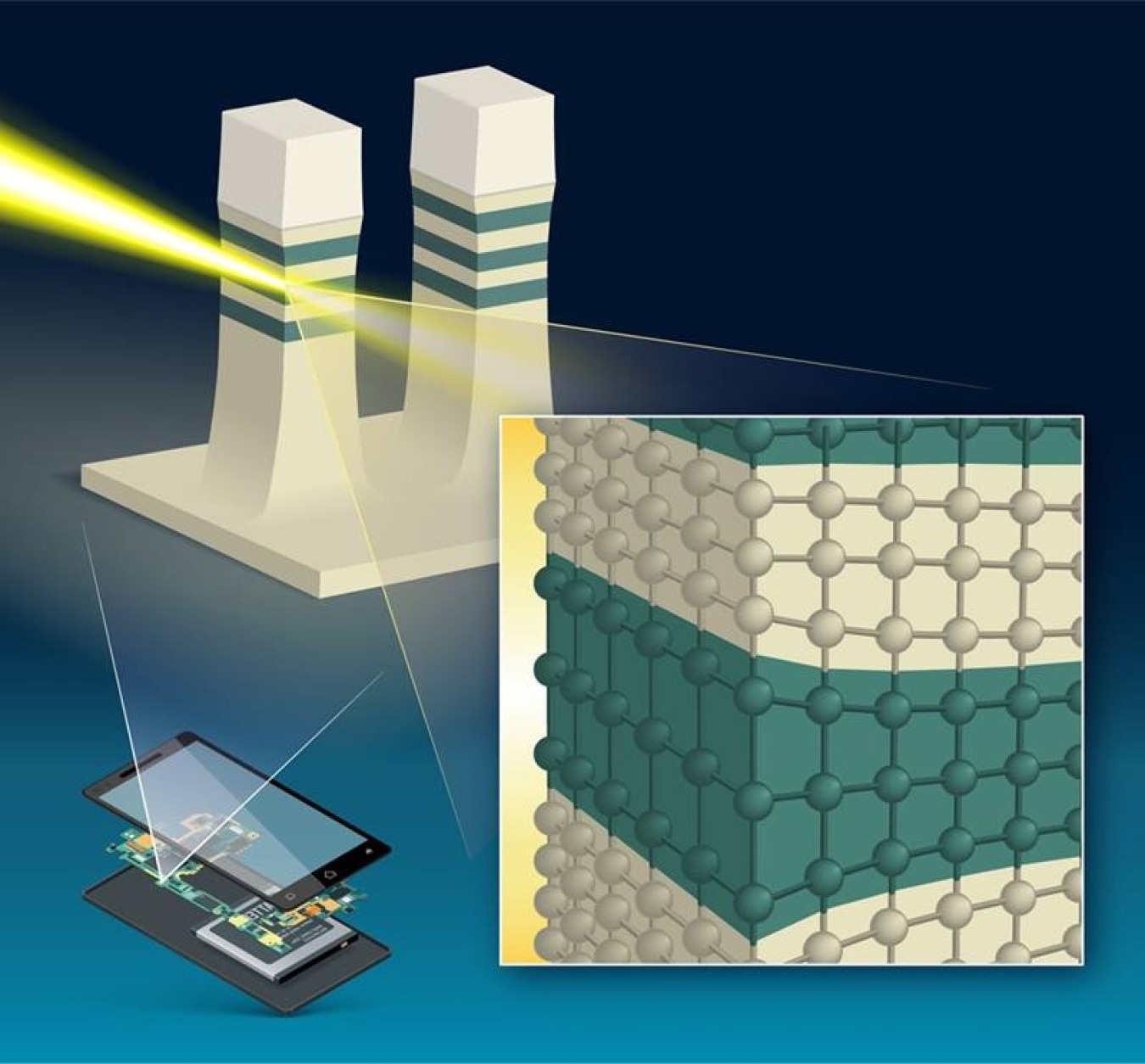

Artist’s impression of how X-rays make it possible to study the distortions of the layers in the microelectronics material. The atoms at the edges of the layers are either squished tighter or pulled apart, creating a bend along the different layers. Image Credit: Brookhaven National Laboratory

Artist’s impression of how X-rays make it possible to study the distortions of the layers in the microelectronics material. The atoms at the edges of the layers are either squished tighter or pulled apart, creating a bend along the different layers. Image Credit: Brookhaven National Laboratory

As electronic devices shrink, researchers are developing new technologies using nanoscale materials. These materials include ultra-thin layered structures called “nanosheets.”

Understanding how these devices function at the microscopic level helps researchers apply them in microelectronics. However, their small size makes it difficult to study them without altering or damaging their original structure.

The Impact

Consumers expect electronic devices to be smaller and faster. However, manufacturing high-performance circuits at the nanoscale is complex. These small structures often contain flaws and deformations that can affect device performance. Studying these imperfections - without causing additional damage - is essential for applying nanoscale materials in real-world devices.

This study presents a non-destructive method to examine nanosheet structures at the nanoscale. It also provides insight that could support the development of new nanostructures for electronic applications.

Summary

Nanosheets are used in advanced electronic components known as Gate-All-Around Field Effect Transistors (GAAFETs). These components form the basis of microprocessors, which power smartphones and computers.

In this study, IBM researchers collaborated with scientists from the National Synchrotron Light Source II (NSLS-II), a Department of Energy Office of Science user facility at Brookhaven National Laboratory. They mapped deformations within nanosheets using the Hard X-ray Nanoprobe (HXN) beamline at NSLS-II.

By combining a high-intensity X-ray source with a nanofocusing optics setup called a multilayer Laue lens, the team observed two deformation mechanisms at different length scales. The first is a long-range process, already known, resulting from lattice constant mismatches between material layers and edge relaxation.

The second process is short-range and linked to the layered structure of the nanosheets. It occurs within a distance comparable to the nanosheet thickness from the edge. These findings could help researchers better predict key performance characteristics in future devices, such as carrier mobility.

The study used resources from the National Synchrotron Light Source II, a facility supported by the U.S. Department of Energy Office of Science.

Journal Reference:

Murray, C. E., et al. (2022) Mapping of the mechanical response in Si/SiGe nanosheet device geometries. Communications Engineering. doi.org/10.1038/s44172-022-00011-w.