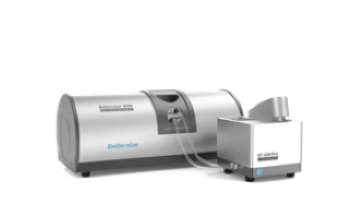

The Bettersizer 2600 utilizes the widely recognized Laser Diffraction Technology for particle measurement, with a range of particle sizes from 0.02 to 2,600 μm. A total of 92 photoelectric detectors transform light signals into electrical signals, which are transmitted into intelligent software from the scattering spectrum. A precise and reliable particle size distribution can be obtained by applying the Mie scattering theory to the data and carrying out mathematical conversion.

Due to its modular design, the Bettersizer 2600 has many uses. The dynamic imaging module allows for combined laser and imaging tests, offering both particle shape and size analysis and expanding the measurement range to 3,500 μm. The various dispersion system modules accommodate a broad spectrum of testing requirements, including wet and dry dispersion techniques to satisfy different testing specifications.

BT-A60 Autosampler | Automated Efficiency in Particle Test

Video Credit: Delta-T Devices Ltd

Features and Benefits

- Auto-alignment of the laser diffraction system: elimination of manual adjustments

- Modular dual-camera imaging system: 24 detailed particle parameters

- Seamless switching dispersion units: adaptability to both dry and wet methods

- User-friendly software: efficiency and ease of use

- Compliance with ISO 13320, 21 CFR Part 11, USP <429>, ISO 13322-2

- Measurement: Particle size and shape

- Wide particle size range: wet dispersion: 0.02–2,600 μm; dry dispersion: 0.1–2,600 μm; dynamic image: 2.0–3,500 μm

- Dual optical system: Laser Diffraction and Dynamic Imaging

- Advanced laser diffraction system: A Combination of Fourier and inverse Fourier design

- 92 distributed spherical detectors array: detection of light signals 0.016–165°

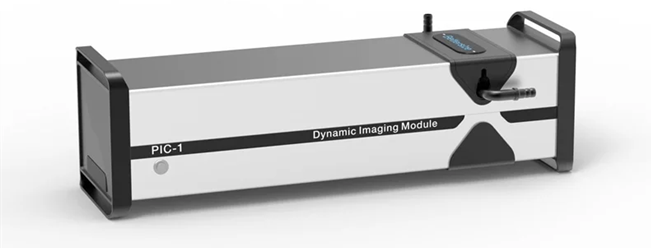

Dynamic Imaging Module: PIC-1. Image Credit: Bettersize Instruments Ltd.

The PIC-1 dynamic imaging module is a flexible and comprehensive dynamic image analysis tool that is designed to work seamlessly with the Bettersizer 2600 laser particle size analyzer and wet dispersion systems.

Parameter and Specification of PIC-1 Dynamic Imaging Module

- Particle size range: 2–3,500 μm

- Size and shape parameters: 24

- Camera type: CCD sensor, 1.5 Megapixels

- Magnification: 0.5× and 10×

- Imaging rate: 120 fps

- Illumination: White and blue LED

- Image recognition: Up to 10,000 particles per minute

Source: Bettersize Instruments Ltd.

| Sample Dispersion Modules |

BT-802 |

BT - 804 |

BT-80N |

BT - 80N Pro |

BT-902 |

BT-903 |

| Sample Dispersion |

Wet sample dispersion |

Wet small volume sample dispersion |

Anti-corrosive sample dispersion |

Anti-corrosive Wet sample dispersion |

Dry sample dispersion |

Dry small volume sample dispersion |

| Dispersion Modules |

|

|

|

|

|

|

| Combine with Main Device |

|

|

|

|

|

|

| Volume / Sample Mass |

600 mL |

8 mL |

50 - 80 mL (dispersion medium) |

80 - 200 mL

(dispersion medium) |

0.2 g-10 g |

0.05 g-1 g |

| Automation |

Fully automated |

Semi-automated |

Semi-automated |

Fully automated |

Fully automated |

Fully automated |

Intuitive and Powerful Software

- Easy to operate and a clear, intuitive interface

- Simple standard operating procedures

- Automatic cleaning routine

- Real-time mode to determine optimal measurement parameters

- Fully automated measurement procedure with automatic calibration

- Single-button click to switch from wet to dry dispersion

- Automatic data backup and editable reports

- Based on sample size and type, accurate analysis is accomplished through suitable implementation of the Fraunhofer or Mie evaluation models

Applications

The following domains are among those where the instrument is used:

- Abrasives

- Batteries

- Building Materials

- Ceramics

- Cosmetics

- Food and Beverage

- Mining and Materials

- Paints, Inks, and Coatings

- Pharmaceuticals

- 3D Printing Materials

Image Credit: Bettersize Instruments Ltd.