Bettersize Instruments’ PowderPro A1 intelligent powder characteristics tester integrates a wide range of state-of-the-art technologies, including image processing, 3D electromagnetic vibration, and intelligent control via Wi-Fi.

This allows the instrument to measure the physical properties of powders quickly, simply, and accurately. This intelligent powder characteristics tester is essential for any user looking to research and better understand powdered materials.

The PowderPro A1 offers several useful features, including:

- A compact, space-saving design

- Multiple controls

- Intelligent data transmission capabilities

- Data output in a convenient format

- Time-saving automated control technology

- Convenient automated imaging technology

Bulk Density Testing of Non-metallic Powder Materials with PowderPro A1

Bulk Density Testing of Non-metallic Powder Materials with PowderPro A1. Video Credit: Bettersize Instruments

Benefits of the PowderPro A1 Powder Characteristics Tester

Measurement and Calculation Capabilities

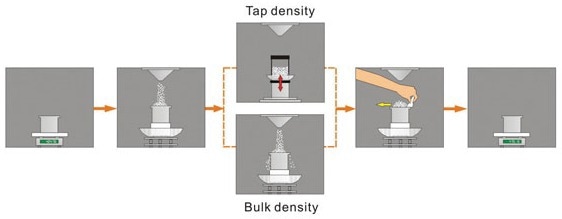

The PowderPro A1 can fully and automatically measure the angle of spatula (flat plate angle), angle of repose and fall, voidage and cohesion, bulk and tapped densities, and dispersibility.

It can also calculate compressibility, angle of difference, uniformity, sieve size, floodability index, and flowability index.

Angles can be measured utlizing the image method with images acquired using high-definition CCD imaging technology. Parameters including angle of spatula, angle of fall and angle of repose can be obtained quickly and easily, ensuring good repeatability and high precision due to the PowderPro A1’s unique image recognition and processing technology.

Technological Advantages

The instrument’s patented rotary vibration technology improves measurement accuracy by ensuring the powder maintains a smooth surface.

Its technology allows for fully automatic mobile or PC control, ensuring ease of use and operation. Accurate and reliable test results can be obtained for standardized testing processes via SOP mode.

Results from the PowderPro A1 powder characteristics tester conform to USP 32-NF27<616>, ISO 3953:1993, and Ph. Eur.7.0 07/2010:20934E standards.

Data is communicated using an electronic scale connected to the instrument. Weight data is automatically transferred for data processing and results calculation.

Tapped density is achieved using an innovative combination of variable frequency and rotary vibration.

The vibration frequency of 50 to 300 times per minute can be continuously adjusted, while a variable vibration amplitude of either 3 mm or 14 mm can be selected. The cylinder is kept in a uniform rotation state during vibration, ensuring a horizontal powder surface and improving the accuracy of the measurement.

Measure Angle of Repose

Image Credit: Bettersize Instruments

Measure Bulk Density and Tapped Densit

Image Credit: Bettersize Instruments

Specification

Source: Bettersize Instruments Ltd.

| Specification of PowderPro A1 Powder Characteristics Tester |

| Powder |

Type |

Metallic Materials (Fe, Ni, alloy, etc.) |

| |

|

Non-metallic Materials (CaCO3, SiO2, Polymer, etc.) |

| Parameters |

Number |

9 (Measured) + 5 (Calculated) |

| Measuring Angle |

Method |

Fully Automatic by CCD Camera |

| |

Range |

0-90° |

| Repeatabillty |

|

≤ 3% |

| Tapping |

Frequency |

50-300 taps/min (Continuous Adjustment) |

| |

Stroke Height |

3 or 14 mm |

| |

Display |

Digital Display |

| Conformity |

ISO |

ISO 3953: 2011 |

| |

USP |

USP 32 - NF 27 <616> |

| |

Ph. Eur |

Ph. Eur. 7.0 07 / 2010: 20934E |

| Control Terminal |

Tablet |

Android System |

| |

Phone |

Android System |

| |

PC |

Windows System |

| Connection |

|

Wi-Fi, LAN |

| Dimensions |

|

600 × 350 × 730 mm (L × W × H) |

| Weight |

|

42 kg |

| Power supply |

|

AC 110/220 V, 50/60 Hz, 230 W |