Carbon nanotubes were a laboratory novelty in the nineties, but are now becoming increasingly popular in aerospace engineering. Their exceptional strength, thermal stability, and conductivity are used in aircraft design, from lightweight composites to smart sensing systems and electromagnetic shielding. However, challenges remain in scaling their production.

Image Credit: Jaromir Chalabala/Shutterstock.com

Image Credit: Jaromir Chalabala/Shutterstock.com

Core Properties of CNTs

Discovered in 1991, carbon nanotubes (CNTs) are cylindrical structures made of graphene sheets rolled into nanoscale tubes. Their atomic structure gives rise to exceptional properties: mechanical strength greater than steel, electrical conductivity akin to metals, and thermal conductivity several times greater than copper.

These characteristics make CNTs ideal candidates in aerospace technology, where strength-to-weight ratio, thermal management, and electronic integration are essential. Both single-walled (SWCNTs) and multi-walled CNTs (MWCNTs) have demonstrated exceptional strength, thermal stability under extreme conditions, and unmatched thermal conductivity when integrated into structural and functional components, particularly in advanced composites.1

CNTs for Mechanical Reinforcements and Lightweight Structures

When used for rocket structures and hypersonic aircraft, traditional composites often undergo delamination failure. This has forced experts to look for alternatives.

Unlike these materials, CNT-reinforced composites have improved mechanical stability, reduced brittleness, and embedded sensing capabilities. Furthermore, innovative CNT materials integrated within the composites can function as highly sensitive strain meters for detecting faults, cracks, and imperfections, making them highly useful for live damage monitoring.

Researchers at the University of Texas at Dallas have taken advantage of these properties by integrating ultra-thin sheets of MWCNTs into the interfacial layers of a composite sandwich structure. Through end-notched flexural testing, they found this incorporation resulted in a 37 % increase in flexural strength and a 126 % improvement in fracture toughness, despite a negligible increase in mass.

The MWCNTs also reduced the stress concentration points and enabled a shift from brittle failure towards a stable ductile failure mode, which is critical in aerospace safety.2

This composite incorporating MWCNTs is suitable for mechanical components, de-icing applications, and structural health monitoring of aerospace parts.

NASA’s Super-lightweight Aerospace Composites Project

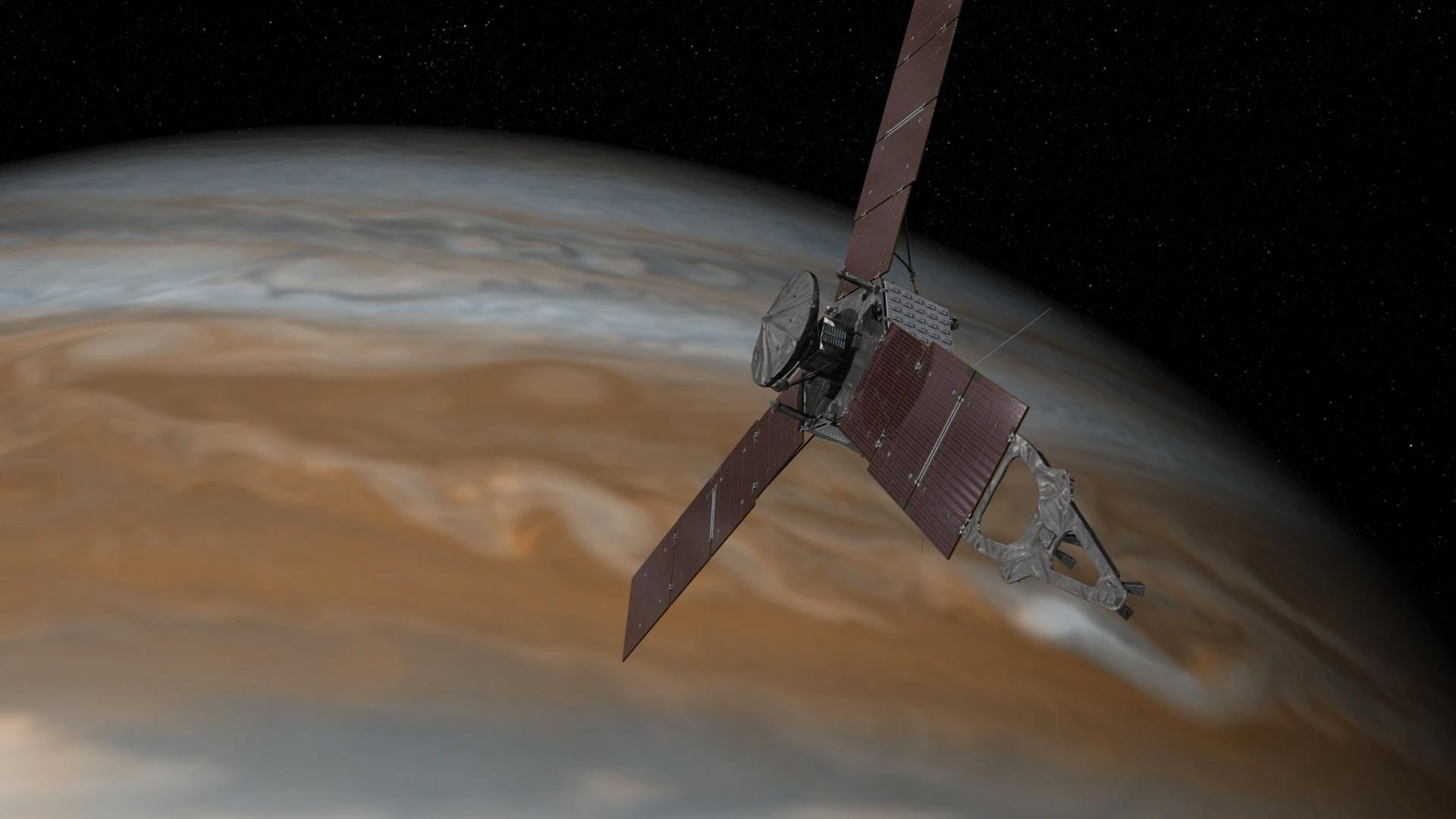

NASA's super-lightweight aerospace composites project is accelerating efforts to scale up CNT production and incorporate them into high-performance structures. They have already used CNT-based materials in the Juno spacecraft, including in engine tubes, thermal shielding, and structural covers.

Image Credit: NASA/JPL-Caltech

Image Credit: NASA/JPL-Caltech

CNT yarns and composite materials are also being tested in sounding rockets in an attempt to achieve a higher Manufacturing Readiness Level in the next few years. Currently at MRL 2, NASA aims to reach MRL 6, a stage at which the technology can be considered for broader operational use.3

CNTs for Thermal Management Systems

During flight, planes and other aerospace vehicles endure increasing thermal loads, from atmospheric re-entry, high-speed flight, or onboard electronics. CNTs are a compelling material for mitigating this effect. Their high thermal conductivity and resistance to heat make them suitable for both protection and heat dissipation.

Recent studies have used vertically aligned CNTS grown via chemical vapor deposition to improve the thermal conductivity of composite films. After surface modification and integration into a poly(vinyl alcohol) matrix, these films achieved thermal conductivities up to 14.9 W/mK, more than 50 times greater than the unmodified polymer.

These kinds of adaptations are invaluable in the thermal protection systems of spacecraft.4

CNTs for Sensing Mechanisms in Aircraft and Spacecraft

Beyond their mechanical and thermal roles, CNTs are being used as embedded sensors within aerospace structures. When integrated into composites, CNTs can monitor strain and temperature during flight, functioning as distributed sensing networks.

In one study, CNTS showed negative resistance coefficient behaviour, where resistance decreased as temperature increased. Furthermore, CNTs proved to be useful for accurate measurements across a wide range of temperatures (from -70 °C to 180 °C).5

Other sensor designs have combined MWCNTs with MXene powders, forming thin-film layers of just 20 µm. They designed a mechanical testing framework specifically for testing the sensor functionality and its capability for structural health monitoring.

Tests using this framework demonstrated the films’ long-term durability and stable resistance behavior even after 1000 cycles of tensile loads. The Gauge factor of the resulting CNT-based sensing film was found to be around 115.3, making it a highly stable platform for health monitoring of aerospace components.6

Download your PDF now!

Electromagnetic (EMI) Shielding and De-Icing Applications

CNTs are also being used in electromagnetic interference (EMI) shielding, a growing area as aerospace systems are becoming increasingly electronically complex. Because of their high conductivity and lightweight structure, CNT films can deliver shielding over 60 dB across key frequency ranges, even in harsh environments.

Experts created a CNT-glassy carbon composite film using a multi-step process, wrapping the ultra-thin material around CNTs to form a core-shell network structure. This structure maintained its shielding performance even after a week of continuous exposure to 200 °C temperatures.

Additionally, the CNT material successfully demonstrated Joule heating capability as its surface temperature was measured to be around 135 at 3V, also enabling fast anti-icing or de-icing response.7 The exceptional attributes of the CNT-based GC film proved the effectiveness of the nanotube material in EMI shielding.

Scientists have also used spin-coated MWCNTs for de-icing applications. They enabled functional stability at -20 degrees and initiated a de-icing process in under a minute. Their high radio-frequency transmission and fast thermal response make them extremely attractive for next-generation aircraft and UAVs.

Challenges in Scaling and Manufacturing

Despite the popularity of CNTs for aerospace applications, bulk production of error-free CNTs is still quite challenging. However, experts are performing extensive research studies to resolve these challenges and understand the correlation between their attributes and morphology.9

References and Further Reading

- Aerospace America, American Institute of Aeronautics and Astronautics (AIAA), (2020). Resetting expectations for carbon nanotubes. Materials and Structures. [Online]. Available at: https://aerospaceamerica.aiaa.org/features/resetting-expectations-for-carbon-nanotubes/ [Accessed on: August 15, 2025].

- Cao, D. et. al. (2024). Strengthening sandwich composites by laminating ultra-thin oriented carbon nanotube sheets at the skin/core interface. Composites Part B: Engineering. 280. 111496. Available at: https://doi.org/10.1016/j.compositesb.2024.111496

- Siochi, E. Langley Research Center, United States. (2024). Superlightweight Aerospace Composites: Technology Maturation of Structural Carbon Nanotubes. STMD Monthly Technical Briefing. NTRS: NASA Technical Reports Server. 20240012767. [Online]. Available at: https://ntrs.nasa.gov/api/citations/20240012767/downloads/STMD%20Tech%20Brief%2010-22-24b.pdf [Accessed on: August 15, 2025].

- Peng, J. et. al. (2025). Vertically Oriented Carbon Nanotubes for Thermal Management. ACS Applied Nano Materials. 8(6). 3219–3226. Available at: https://doi.org/10.1021/acsanm.4c07152

- Karlsson, T. et. al. (2023). Sensing abilities of embedded vertically aligned carbon nanotube forests in structural composites: From nanoscale properties to mesoscale functionalities. Composites Part B: Engineering. 255. 110587. Available at: https://doi.org/10.1016/j.compositesb.2023.110587

- Zhang, L. et. al. (2022). Lifetime health monitoring of fiber reinforced composites using highly flexible and sensitive MXene/CNT film sensor. Sens. Actuators A Phys. 332. 113148. Available at: https://doi.org/10.1016/j.sna.2021.113148

- Zhang, D. et al. (2024). Ultra-thin robust CNT@GC film integrating effective electromagnetic shielding and flexible Joule heating. Nano Res. 17, 3462–3471. Available at: https://doi.org/10.1007/s12274-023-6349-8

- Zecchi, S. et. al. (2025). A Concise Review of Recent Advancements in Carbon Nanotubes for Aerospace Applications. Micromachines. 16(1). 53. Available at: https://doi.org/10.3390/mi16010053

- Syduzzaman, M. et. al. (2025). Carbon nanotubes: Structure, properties and applications in the aerospace industry. Results in Materials. 25. 100654. Available at: https://doi.org/10.1016/j.rinma.2024.100654

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.