In industries where dry powder analysis is essential, such as pharmaceuticals, cement manufacturing, additive manufacturing, and more, precision, efficiency, and flexibility are critical.

Yet, for too long, dry powder systems have remained large, stationary, and challenging to integrate into fast-paced, dynamic work environments.

The ground-breaking invention, the Raptor Portable Dry Powder Analyzer, is the first dry powder system made especially to be portable without compromising functionality.

Why Portability Matters in Dry Powder Analysis

Traditional dry powder systems require samples to be transported to a central analysis lab, a process that can lead to:

- Sample contamination

- Loss of critical time

- Reduced efficiency in production workflows

The Raptor Portable Dry Powder Analyzer eliminates these challenges by allowing engineers, operators, and quality control specialists to perform advanced dry powder analysis right where it's needed - whether on the production floor, in a clean room, or out in the field.

Key Features of the Raptor Portable Dry Powder Analyzer

- Truly Portable: A lightweight, compact design that integrates seamlessly into existing workflows without causing disruption.

- High-Precision Measurement: Utilizes dynamic image analysis to deliver accurate particle size and shape data.

- Easy-to-use Interface and Tools: An intuitive dashboard with built-in tools for fast, informed decision-making in the field - no expertise required.

- Versatile Application: Designed to handle a broad range of powders, including pharmaceutical excipients, cement powders, specialty chemicals, and more.

- Rugged Design: Engineered for mobility without compromising the durability needed for demanding industrial environments.

- Thumbnail Images: See what’s really in your sample. Thumbnail images provide clear, visual evidence - so anyone can interpret the results and act with confidence on the spot.

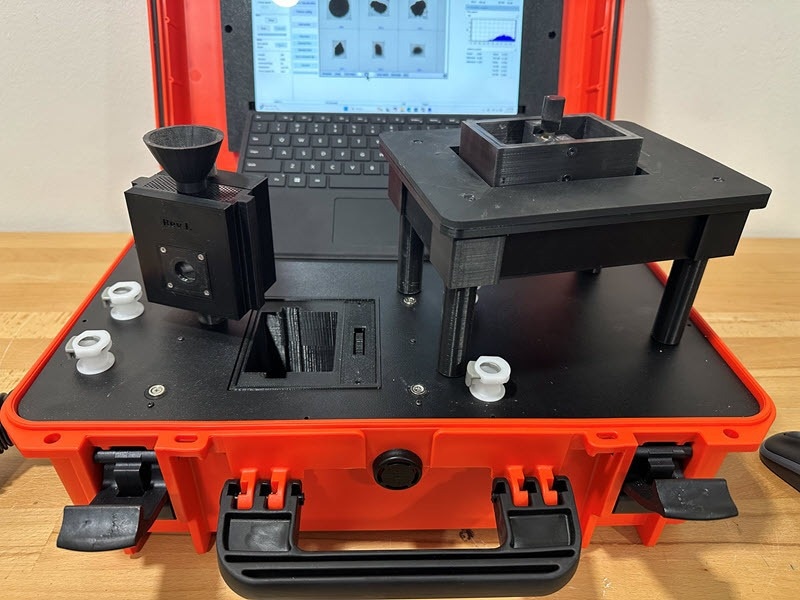

Dry Powder Module on Raptor Portable particle size and shape analyzer. Image Credit: Vision Analytical Incorporated

Industries That Will Benefit

- Pharmaceutical Industry: Conduct real-time analysis of active ingredients and excipients without ever leaving the cleanroom or production site.

- Cement and Construction Materials: Monitor particle size distribution and material consistency on-site to safeguard product quality and optimize formulations.

- Chemical Manufacturing: Examine specialty powders without compromising sample integrity or stopping the manufacturing process.

- Advanced Manufacturing & 3D Printing: Maintaining the proper particle properties will help to maximize powder bed fusion and other additive manufacturing procedures.

Setting a New Standard

With the Raptor Portable Dry Powder Analyzer, Vision Analytical Incorporated defining what’s possible in powder analysis. It’s more than just a tool - it’s a driver of faster insights, better-quality production, and more agile operations.

Whether you're ensuring pharmaceutical quality, producing top-grade cement, or pushing the boundaries of advanced manufacturing, the Raptor empowers you to analyze faster, work smarter, and stay mobile.

Raptor Portable Analyzer: Dry Powder Module Demonstration for Particle Analysis

Video Credit: Vision Analytical Incorporated