Voice coil motors are direct drives conveying the force of the drive element directly to the load without using mechanical transmission parts, such as a coupling, drive screw, or gearhead.

Voice coil drives are made up of a permanent magnet and a winding body positioned in the magnetic field’s air gap.

The winding body moves when current flows through it, causing the permanent magnet’s magnetic field to change.

Voice coil drives are particularly well suited for applications with high dynamics and velocities at constrained travel ranges due to their low weight and friction-free drive mechanism. These drives are free from the effects of hysteresis, enabling high scan frequencies and precise positioning.

Features

- Compact design

- Durable and friction-free thanks to flexures

- Noncontact direct position measuring with linear encoders

- Beam deflection angle to 8°

- Two orthogonal tip/tilt axes with a common center of rotation

- Identical motion characteristics of both axes thanks to parallel kinematics

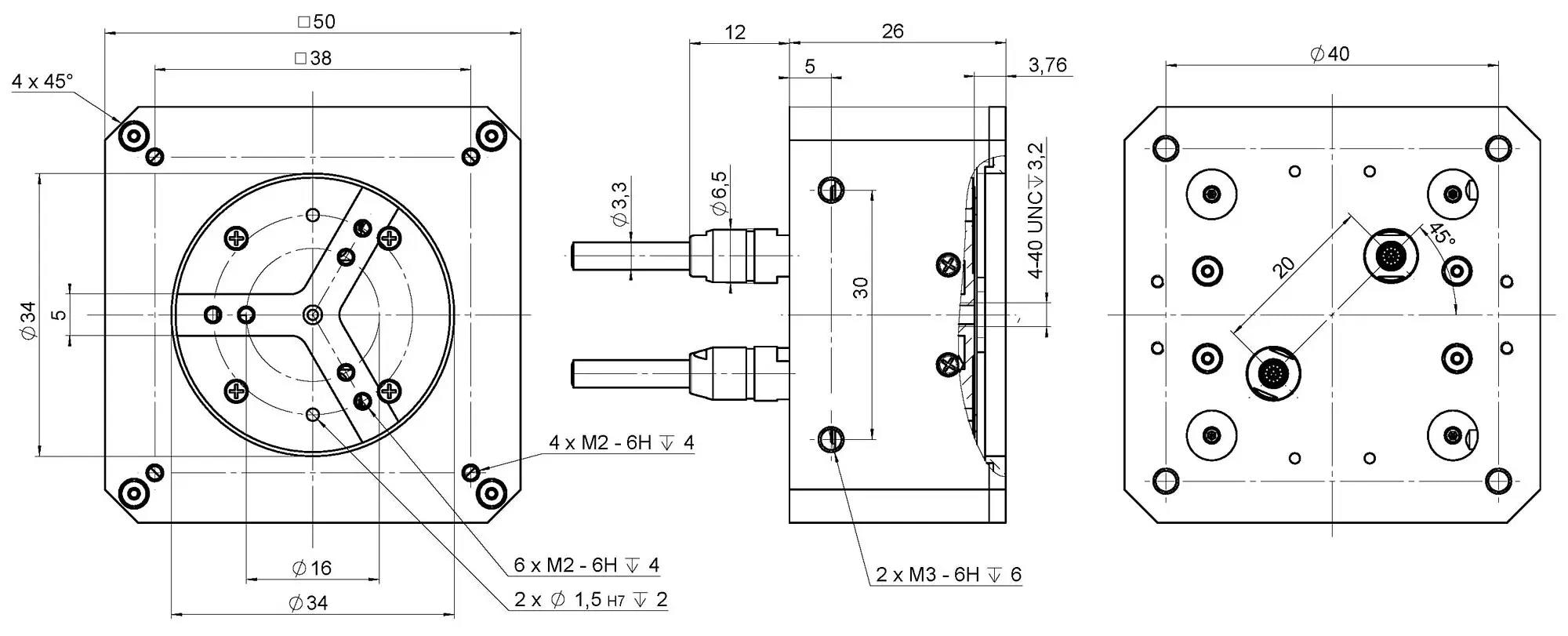

V-931.01, dimensions in mm. Image Credit: PI (Physik Instrumente) LP

High Dynamics Multi-Axis Operation Due to Parallel Kinematics

All actuators in a parallel-kinematic multi-axis system operate on a single platform. The axes’ uniform designs and low mass inertia make fast, dynamic, and precise motion possible.

Application Fields

- Test and inspection: AOI (automated optical inspection), noncontact profilometry, sensor testing

- Optics: Optical filters/switches, optical trapping, grid scan, tracking

- Beam stabilization

- Satellite communication

- Image processing/stabilization

- Laser micromachining. Laser tuning and laser scanning/beam steering with large deflection angles

Specifications

Source: PI (Physik Instrumente) LP

| Motion |

V-931.01 |

Tolerance |

| Active axes |

θX θY |

|

| Rotation range in θX |

± 2 ° |

|

| Rotation range in θY |

± 2 ° |

|

| Linearity error in θX |

0.2 % |

typ. |

| Linearity error in θY |

0.2 % |

typ. |

| Positioning |

V-931.01 |

Tolerance |

| Integrated sensor |

Incremental linear encoder |

|

| Bidirectional repeatability in θX |

± 2 µrad |

typ. |

| Bidirectional repeatability in θY |

± 2 µrad |

typ. |

| Minimum incremental motion in θX |

1 µrad |

max. |

| Minimum incremental motion in θY |

1 µrad |

max. |

| Settling time for 100% step in θX |

20 ms |

max. |

| Settling time for 100% step in θY |

20 ms |

max. |

| Sensor resolution, rotational |

1 µrad |

max. |

| Interpolation factor |

65536 |

|

| Sensor supply voltage |

5 V |

±10 % |

| Drive Properties |

V-931.01 |

Tolerance |

| Drive type |

Voice coil |

|

| Nominal voltage |

24 V |

|

| Peak voltage |

24 V |

|

| Nominal current, RMS |

0.5 A |

typ. |

| Peak current, RMS |

1.5 A |

typ. |

| Force constant |

32.8 N·mm/A |

|

| Resistance phase-phase |

13 Ω |

typ. |

| Inductance phase-phase |

1.9 mH |

|

| Mechanical Properties |

V-931.01 |

Tolerance |

| Distance of pivot point to platform surface |

-3.2 mm |

±0,05 mm |

| Resonant frequency in θX, unloaded |

29 Hz |

±20% |

| Resonant frequency in θY, unloaded |

29 Hz |

±20% |

| Overall mass |

290 g |

|

| Mass without cable |

135 g |

|

| |

V-931.01 |

Tolerance |

| Connector |

D-sub 15-pin (m) |

|

| Recommended controllers / drivers |

C-413.2x

|

|

| Cable length |

1 m |

|

| Operating temperature range |

5 to 40 °C |

|

Peak current, RMS: Max. duration 1.0 s

Settling time for 100% step: 44 mrad, 2% settling band, payload: 1-inch mirror 5 mm thickness

Distance of pivot point to platform surface: Gap below the platform's mounting surface