The V-857 is a heavy-duty, highly dynamic linear stage designed for industrial use. Its design is continually geared to harsh industrial settings, with high rigidity and the use of high-quality components, such as recirculating ball bearing guides, three-phase linear motors, and incremental or absolute linear encoders.

Features include:

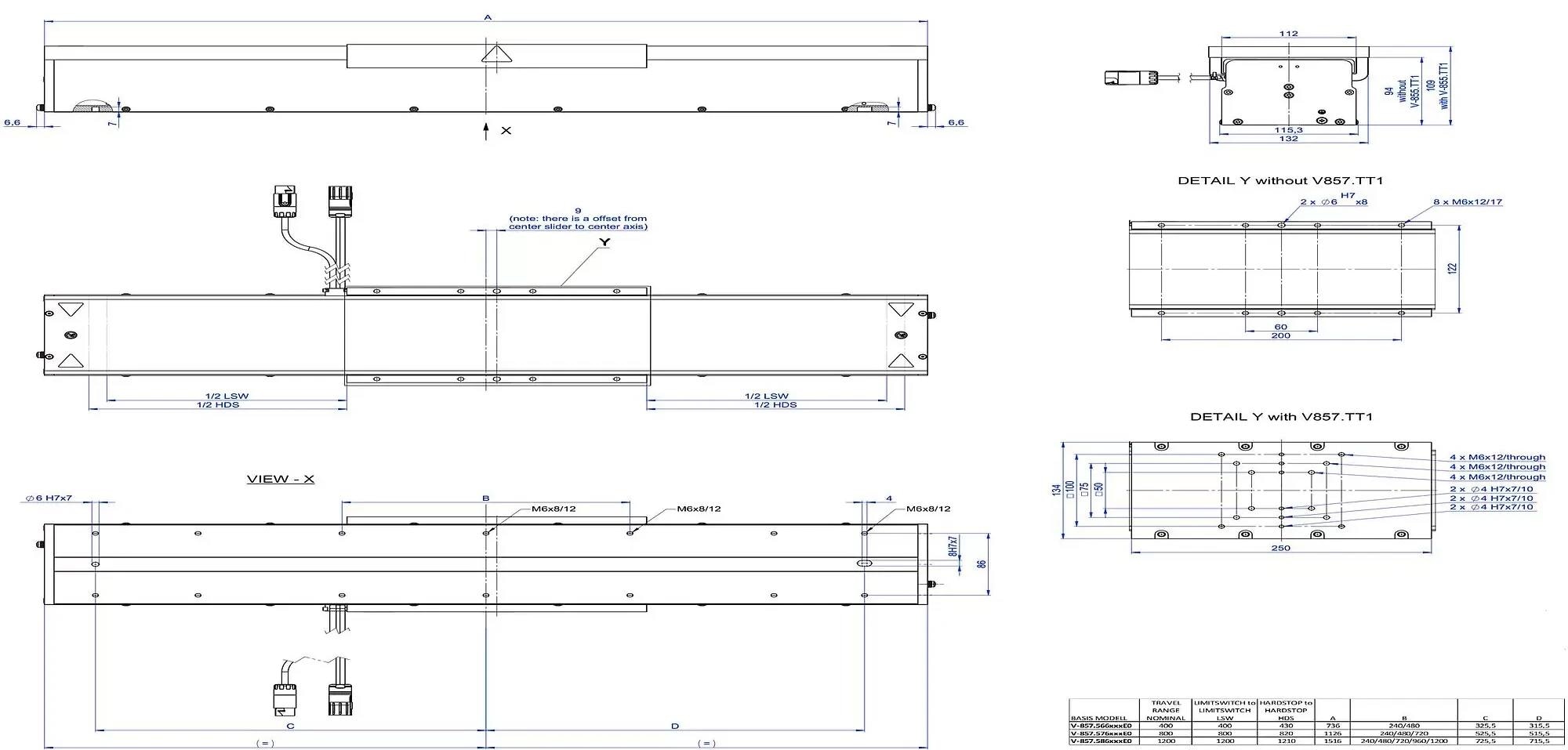

- Long travel ranges (to 800 mm) with narrow profile (132 mm width)

- Highly dynamic, maintenance-free linear motor with velocities up to 5 m/s

- Permanent load capacity to 1000 N

- High-precision incremental or absolute linear encoder

- Sophisticated industrial design for a long lifetime

- Ideal for gantry systems

Linear Motor Stages for High Throughput & Economical Positioning in Precision Industrial Automation

Video Credit: PI (Physik Instrumente) LP

Image Credit: PI (Physik Instrumente) LP

The encoders’ high resolution enables outstanding tracking performance, small tracking errors, and quick settling times. Connectors that are industry-compatible provide rapid and secure connectivity. With a triple M6 hole pattern, the alternative motion platform provides numerous assembly options.

Linear Motor With Direct Drive

Three-phase magnetic direct drives do not require mechanical components in the drivetrain; instead, the drive force is sent directly and without friction to the motion platform. The drives achieve tremendous velocities and accelerations.

Ironless motors are particularly well suited for precision positioning tasks because there is no undesired interaction with the permanent magnets. This enables smooth operation at low speeds while eliminating vibration at high velocities. Control behavior is nonlinear, and any position can be easily controlled. The drive force can be easily adjusted.

Options

Optional accessory: V-857.TT1 motion platform

Application Fields

- Electronics manufacturing includes PCB manufacturing and printed electronics

- Noncontact 2D measurement, inspection sensor and camera positioning, position sensor testing, vibration, and acceleration testing

- Robotic manipulation and microassembly, as well as industrial inkjet printing, are examples of advanced manufacturing

Specifications

400 m

Table 1. Source: PI (Physik Instrumente) LP

| Motion |

V-857.566023E0 |

V-857.566211E0 |

V-857.576023E0 |

V-857.576211E0 |

Tolerance |

| Active axes |

X |

X |

X |

X |

|

| Travel range in X |

400 mm |

400 mm |

800 mm |

800 mm |

|

| Acceleration in X, unloaded |

50 m/s² |

50 m/s² |

50 m/s² |

50 m/s² |

max. |

| Maximum velocity in X, unloaded |

5000 mm/s |

5000 mm/s |

5000 mm/s |

5000 mm/s |

|

| Straightness (Linear crosstalk in Y with motion in X) |

± 12 µm |

± 12 µm |

± 20 µm |

± 20 µm |

max. |

| Flatness (Linear crosstalk in Z with motion in X) |

± 10 µm |

± 10 µm |

± 10 µm |

± 10 µm |

max. |

| Pitch (Rotational crosstalk in θY with motion in X) |

± 100 µrad |

± 100 µrad |

± 150 µrad |

± 150 µrad |

max. |

| Yaw (Rotational crosstalk in θZ with motion in X) |

± 150 µrad |

± 150 µrad |

± 200 µrad |

± 200 µrad |

max. |

| Positioning |

V-857.566023E0 |

V-857.566211E0 |

V-857.576023E0 |

V-857.576211E0 |

Tolerance |

| Integrated sensor |

Absolute linear encoder |

Incremental linear encoder |

Absolute linear encoder |

Incremental linear encoder |

|

| System resolution in X |

1 nm |

0.3 nm |

1 nm |

0.3 nm |

|

| Bidirectional repeatability in X |

± 0.5 µm |

± 0.5 µm |

± 0.5 µm |

± 0.5 µm |

max. |

| Positioning accuracy in X, uncalibrated |

± 15 µm |

± 15 µm |

± 20 µm |

± 20 µm |

max. |

| Minimum incremental motion in X |

0.1 µm |

0.1 µm |

0.1 µm |

0.1 µm |

max. |

| Sensor signal |

BiSS-C |

Sin/cos, 1 V peak-peak |

BiSS-C |

Sin/cos, 1 V peak-peak |

|

| Sensor resolution |

5 nm |

|

5 nm |

|

|

| Sensor signal period |

|

20 µm |

|

20 µm |

|

| Limit switches |

|

Hall effect, N/C contact, 5 V, NPN |

|

Hall effect, N/C contact, 5 V, NPN |

|

| Drive Properties |

V-857.566023E0 |

V-857.566211E0 |

V-857.576023E0 |

V-857.576211E0 |

Tolerance |

| Drive type |

Ironless 3-phase linear motor |

Ironless 3-phase linear motor |

Ironless 3-phase linear motor |

Ironless 3-phase linear motor |

|

| Nominal voltage |

320 V |

320 V |

320 V |

320 V |

|

| Peak voltage |

320 V |

320 V |

320 V |

320 V |

|

| Nominal current, RMS |

6 A |

6 A |

6 A |

6 A |

typ. |

| Peak current, RMS |

21 A |

21 A |

21 A |

21 A |

typ. |

| Drive force in negative direction of motion in X |

120 N |

120 N |

120 N |

120 N |

typ. |

| Drive force in positive direction of motion in X |

120 N |

120 N |

120 N |

120 N |

typ. |

| Peak force in negative direction of motion in X |

420 N |

420 N |

420 N |

420 N |

|

| Peak force in positive direction of motion in X |

420 N |

420 N |

420 N |

420 N |

|

| Force constant |

20 N/A |

20 N/A |

20 N/A |

20 N/A |

|

| Motor constant |

9.7 N/√W |

9.7 N/√W |

9.7 N/√W |

9.7 N/√W |

typ. |

| Time constant |

0.35 ms |

0.35 ms |

0.35 ms |

0.35 ms |

|

| Resistance phase-phase |

2.8 Ω |

2.8 Ω |

2.8 Ω |

2.8 Ω |

typ. |

| Inductance phase-phase |

1 mH |

1 mH |

1 mH |

1 mH |

|

| Back EMF phase-phase |

16 V·s/m |

16 V·s/m |

16 V·s/m |

16 V·s/m |

max. |

| Pole pitch N-N |

30 mm |

30 mm |

30 mm |

30 mm |

|

| Mechanical Properties |

V-857.566023E0 |

V-857.566211E0 |

V-857.576023E0 |

V-857.576211E0 |

Tolerance |

| Guide |

Recirculating ball bearing guide |

Recirculating ball bearing guide |

Recirculating ball bearing guide |

Recirculating ball bearing guide |

|

| Moved mass in X, unloaded |

2300 g |

2300 g |

2300 g |

2300 g |

|

| Permissible push force in Y |

100 N |

100 N |

100 N |

100 N |

max. |

| Permissible push force in Z |

1000 N |

1000 N |

1000 N |

1000 N |

max. |

| Overall mass |

11600 g |

11600 g |

16600 g |

16600 g |

|

| Material |

Aluminum, black anodized, steel (guide rail) |

Aluminum, black anodized, steel (guide rail) |

Aluminum, black anodized, steel (guide rail) |

Aluminum, black anodized, steel (guide rail) |

|

| Miscellaneous |

V-857.566023E0 |

V-857.566211E0 |

V-857.576023E0 |

V-857.576211E0 |

Tolerance |

| Connector |

M15 9-pin (m) |

M15 9-pin (m) |

M15 9-pin (m) |

M15 9-pin (m) |

|

| Sensor connector |

M15 15-pole (m) |

M15 15-pole (m) |

M15 15-pole (m) |

M15 15-pole (m) |

|

| Recommended controllers / drivers |

Ready for use, with fully integrated controller of the G-901 series: G-901.R519, G-901.R5199, G-901.R4199.

Flexible integration with compact modules: ACS SPiiPlusEC and UDMpa.

Also compatible with other third-party controllers and servo drivers.

|

Ready for use, with fully integrated controller of the G-901 series: G-901.R519, G-901.R5199, G-901.R4199.

Flexible integration with compact modules: ACS SPiiPlusEC and UDMpa.

Also compatible with other third-party controllers and servo drivers.

|

Ready for use, with fully integrated controller of the G-901 series: G-901.R519, G-901.R5199, G-901.R4199.

Flexible integration with compact modules: ACS SPiiPlusEC and UDMpa.

Also compatible with other third-party controllers and servo drivers.

|

Ready for use, with fully integrated controller of the G-901 series: G-901.R519, G-901.R5199, G-901.R4199.

Flexible integration with compact modules: ACS SPiiPlusEC and UDMpa.

Also compatible with other third-party controllers and servo drivers.

|

|

| Cable length |

1 m |

1 m |

1 m |

1 m |

|

| Operating temperature range |

5 to 40 °C |

5 to 40 °C |

5 to 40 °C |

5 to 40 °C |

800 m

Table 2. Source: PI (Physik Instrumente) LP

| Motion |

V-857.576023E0 |

V-857.576211E0 |

Tolerance |

| Active axes |

X |

X |

|

| Travel range in X |

800 mm |

800 mm |

|

| Acceleration in X, unloaded |

50 m/s² |

50 m/s² |

max. |

| Maximum velocity in X, unloaded |

5000 mm/s |

5000 mm/s |

|

| Straightness (Linear crosstalk in Y with motion in X) |

± 20 µm |

± 20 µm |

max. |

| Flatness (Linear crosstalk in Z with motion in X) |

± 10 µm |

± 10 µm |

max. |

| Pitch (Rotational crosstalk in θY with motion in X) |

± 150 µrad |

± 150 µrad |

max. |

| Yaw (Rotational crosstalk in θZ with motion in X) |

± 200 µrad |

± 200 µrad |

max. |

| Positioning |

V-857.576023E0 |

V-857.576211E0 |

Tolerance |

| Integrated sensor |

Absolute linear encoder |

Incremental linear encoder |

|

| System resolution in X |

1 nm |

0.3 nm |

|

| Bidirectional repeatability in X |

± 0.5 µm |

± 0.5 µm |

max. |

| Positioning accuracy in X, uncalibrated |

± 20 µm |

± 20 µm |

max. |

| Minimum incremental motion in X |

0.1 µm |

0.1 µm |

max. |

| Sensor signal |

BiSS-C |

Sin/cos, 1 V peak-peak |

|

| Sensor resolution |

5 nm |

|

|

| Sensor signal period |

|

20 µm |

|

| Limit switches |

|

Hall effect, N/C contact, 5 V, NPN |

|

| Drive Properties |

V-857.576023E0 |

V-857.576211E0 |

Tolerance |

| Drive type |

Ironless 3-phase linear motor |

Ironless 3-phase linear motor |

|

| Nominal voltage |

320 V |

320 V |

|

| Peak voltage |

320 V |

320 V |

|

| Nominal current, RMS |

6 A |

6 A |

typ. |

| Peak current, RMS |

21 A |

21 A |

typ. |

| Drive force in negative direction of motion in X |

120 N |

120 N |

typ. |

| Drive force in positive direction of motion in X |

120 N |

120 N |

typ. |

| Peak force in negative direction of motion in X |

420 N |

420 N |

|

| Peak force in positive direction of motion in X |

420 N |

420 N |

|

| Force constant |

20 N/A |

20 N/A |

|

| Motor constant |

9.7 N/√W |

9.7 N/√W |

typ. |

| Time constant |

0.35 ms |

0.35 ms |

|

| Resistance phase-phase |

2.8 Ω |

2.8 Ω |

typ. |

| Inductance phase-phase |

1 mH |

1 mH |

|

| Back EMF phase-phase |

16 V·s/m |

16 V·s/m |

max. |

| Pole pitch N-N |

30 mm |

30 mm |

|

| Mechanical Properties |

V-857.576023E0 |

V-857.576211E0 |

Tolerance |

| Guide |

Recirculating ball bearing guide |

Recirculating ball bearing guide |

|

| Moved mass in X, unloaded |

2300 g |

2300 g |

|

| Permissible push force in Y |

100 N |

100 N |

max. |

| Permissible push force in Z |

1000 N |

1000 N |

max. |

| Overall mass |

16600 g |

16600 g |

|

| Material |

Aluminum, black anodized, steel (guide rail) |

Aluminum, black anodized, steel (guide rail) |

|

| Miscellaneous |

V-857.576023E0 |

V-857.576211E0 |

Tolerance |

| Connector |

M15 9-pin (m) |

M15 9-pin (m) |

|

| Sensor connector |

M15 15-pole (m) |

M15 15-pole (m) |

|

| Recommended controllers / drivers |

Ready for use, with fully integrated controller of the G-901 series: G-901.R519, G-901.R5199, G-901.R4199.

Flexible integration with compact modules: ACS SPiiPlusEC and UDMpa.

Also compatible with other third-party controllers and servo drivers.

|

Ready for use, with fully integrated controller of the G-901 series: G-901.R519, G-901.R5199, G-901.R4199.

Flexible integration with compact modules: ACS SPiiPlusEC and UDMpa.

Also compatible with other third-party controllers and servo drivers.

|

|

| Cable length |

1 m |

1 m |

|

| Operating temperature range |

5 to 40 °C |

5 to 40 °C |